11 - 36

current to a direct current is called a RECTIFIER. A

diode is one type of rectifier.

To check a diode, isolate if from the circuit by

disconnecting one end. With a multitester set on the

lowest ohms scale setting, measure the resistance in

one direction, reverse the test leads, and measure in

the other direction. Readings should be high in one

direction and low in the other. (If the readings are low in

both directions, the diode is shorted, and if the

readings are high, the diode is open.) If the readings

are the same in both directions, the diode is defective

and must be replaced.

IMPORTANT: Diodes are marked to indicate polarity (a

band on one end, an arrow on the side, or they fit on a

holder only one way.

Rectifiers

A battery is charged through the use of an alternator

located in or on the engine. A charging circuit contains

a rectifier because alternators produce alternating

current (AC) and batteries require direct current (DC)

for charging.

The rectifier may be built into the engine or it may be

an external part. It may also contain a regulator to

prevent overcharging the battery. (Servicing of

rectifiers built into the engine should be done by an

approved engine manufacturer’s service center. Such

a service center has access to the information and

parts required to test and repair or replace engine

components, including rectifiers and regulators.)

Units that contain both a rectifier and regulator are

tested in a working circuit to make sure the regulator

portion of the device is operating.

11.9 ELECTRIC CLUTCH

The electric clutch is used to turn on and off the

attachment used on the unit by use of a switch. The

clutch is also designed so that a brake is applied to the

output shaft when the clutch is disengaged (off).

The field coil is mounted to a bearing support and does

not rotate. The rotor is attached to the power output

shaft and rotates around the field assembly. The

armature is attached to the output pulley. The armature

assembly is held close to the rotor by the brake

assembly. The clutch is engaged by applying current to

the coil connection. This results in a current flowing

through the coil, magnetizing the coil pulling the

armature onto the rotor with sufficient force to hold the

two pieces together, effectively connecting the output

and the input shafts together. Pulling the armature

against the rotor pulls it away from the brake, releasing

the brake.

Engine Electrical Components

Engine servicing and repair should be referred to local

engine manufactures service centers that have the

service information and parts available to properly

service the engine. Ariens dealers should be able to

test engines and engine components to pinpoint

troubles and narrow them down to properly advise the

engine serviceman.

IMPORTANT: Check the serial number on the unit. The

serial number will indicate which of the following

sections apply.

11.10 ELECTRICAL FOR SERIAL

NUMBERS ABOVE 10,000

Safety Interlock System

WARNING: Safety Interlock failure and improper

operation of unit can result in death or serious injury.

Check system before each use to make sure it is

functioning properly.

Perform the following tests to ensure the safety

interlock system is working properly.

Initial check out: Make sure that all switches are in their

proper position for starting: (A) PTO off. (B) transaxle in

neutral position. (C) operator on the seat. If there is no

battery voltage to start the engine, use the following

steps to determine the problem.

STEP 1

Check out the battery. Use a voltmeter to check for

proper voltage. Replace the battery if necessary and/or

charge to proper level. Refer to Battery.

STEP 2

Use a voltmeter to make sure you have battery voltage

to terminal B on the back side of the ignition switch in

the off position. If you don’t have battery voltage to

terminal B check the battery connection and the fuse in

the red lead.

STEP 3

With the ignition switch in the "run" position, check to

see if the battery voltage is being transferred from

terminal B to terminal L. Terminal L on the ignition

switch supplies battery voltage to the back of the PTO

switch on the purple lead and on to the neutral switch

on the red/green lead. Then to terminal 86 on the start

relay.

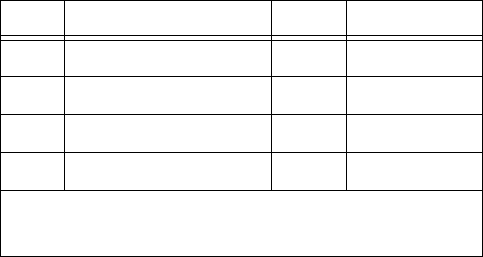

Test Steering Lever PTO Engine

1 Neutral Position Off Starts

2 Neutral Position On Doesn’t Start

4*+ Out of Neutral Position Off Shuts Off

5*+ Neutral Position On Shuts Off

* Test with engine running.

+ Operator lifts off seat.