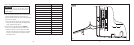

APRILAIRE MODEL

8570 THERMOSTAT

FAN

RELAY

1ST STAGE

AUX. HEAT

R

INDOOR UNIT - AIR HANDLER

C

G

Y2

Y1

W1

W2

L1

L2

120

VAC

24

VAC

2ND STAGE

EMER. HEAT

L

O

Y2

Y1

W1

C

R

1ST STAGE

COMP.

2ND STAGE

COMP.

REV.

VALVE

DEFROST

SERVICE

OUTDOOR UNIT - HEAT PUMP

SUPPLIED JUMPER

1ST STAGE COMP.

2ND STAGE COMP.

ZA

ZB

I+

I-

6504

CONNECTION

B

O

Y2

Y1

G

RC

R

RH

W1

W2

C

AHC

CONNECTION

SINGLE/MULTI – SET TO

MULTI FOR TWO STAGE

HEAT PUMP

ELECT/GAS - SET TO

ELECT FOR ELECTRIC

AUXILIARY HEAT, SET TO

GAS FOR FOSSIL FUEL

(DUAL FUEL) AUXILIARY

HEAT

O/B – SET TO “O” IF HEAT

PUMP REVERSING VALVE

MUST BE ENERGIZED

WHEN COOLING, SET TO

“B” IF IT IS TO BE

ENERGIZED IN HEATING

THERMOSTAT

CONFIGURATION

SWITCH SETTINGS

OUTDOOR (ODT)

& INDOOR (IDS)

TEMPERATURE

SENSORS

HC

SINGLE

B

GAS

HP

MULTI

O

ELECT

4

3

2

1

ON

NC

NO

COM

EVENT

TRIGGERED

OUTPUT

(ETO)

IDS

ODT

GND

Diagram 8: Two-Stage Heat Pump

- 16 - - 17 -

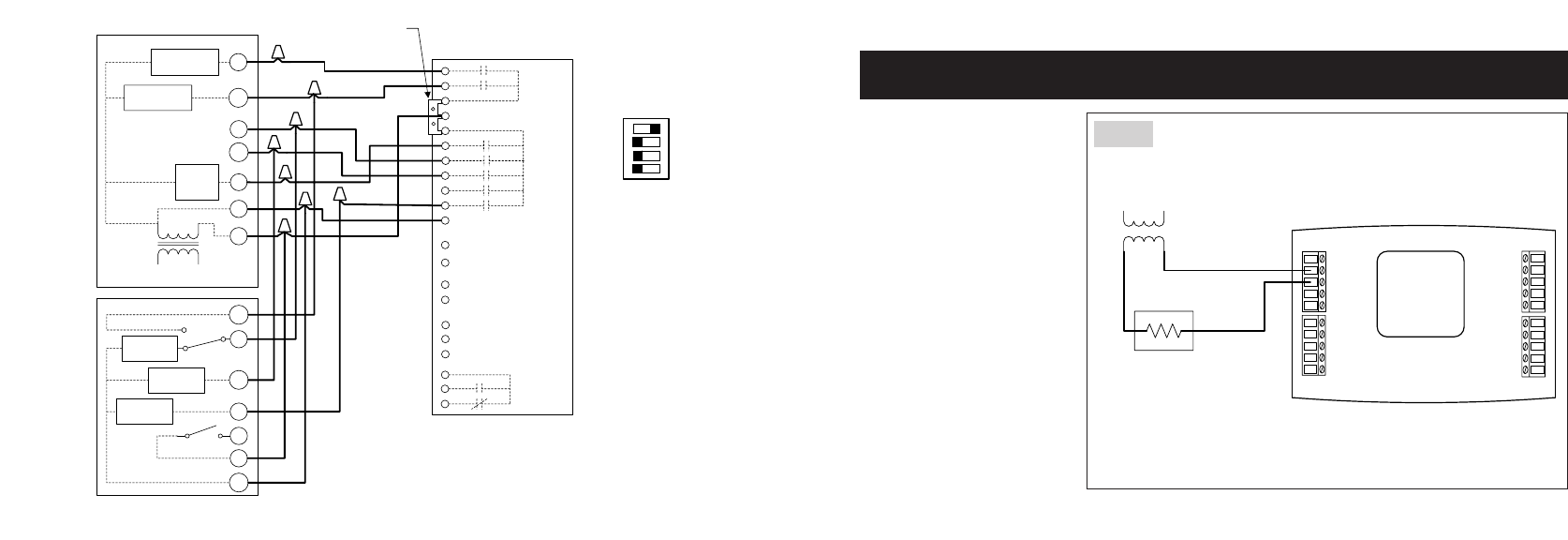

(6) OPTIONAL – WIRE THE EVENT TRIGGERED OUTPUT (ETO)

Terminals NO, COM and NC are the

Normally Open, Common and Normally

Closed outputs, respectively, of a relay

that can be used to control auxiliary

equipment. When the relay is on, a

circuit is complete between NO and

COM; when the relay is off a circuit is

complete between NC and COM. The

relay is programmed to be on or off,

with each of the programming events.

Examples of where this output might

be used include:

• Turn on outdoor ventilation for

programming periods of the day

when the building is occupied and

turn it off when unoccupied.

• Have an electronic air cleaner turn

on and off only when the building is

occupied to reduce maintenance

time/cost.

Y2

Y1

O/B

G

W2

W1

RH

RC

R

C

GND

ODT

IDS

I-

I+

MODEL 8570 THERMOSTAT

(shown with enclosure face removed)

ZB

ZA

NO

COM

NC

USE ONLY TO

CONTROL 24-VOLT

LOADS

LOAD

2A MAX OPERATING CURRENT

3A MAX IN-RUSH CURRENT

Figure 6