19

SECTION F

Polishing Process for Single-mode Connector Return

Loss >40dB

7. PREPARE TO PERFORM THE FINAL POLISH

Using an isopropyl alcohol dampened lint-free cloth, clean the

ferrule and the polishing jig.

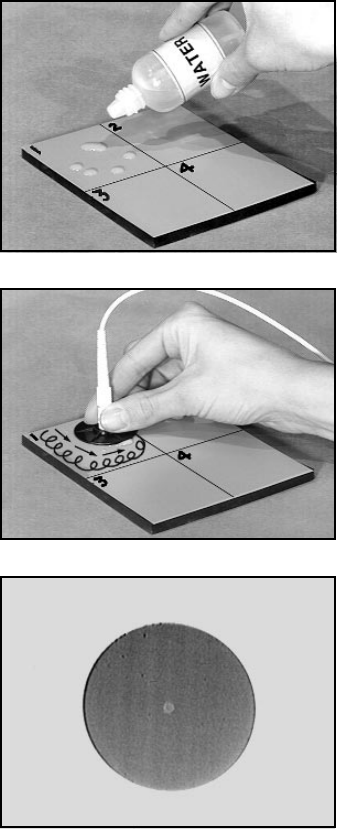

Clean a sheet of the final polishing film and place it shiny side

down onto the clean polishing pad. Section the film into four (4)

quarters. Mark the section 1, 2, 3 and 4. Place a few drops of

water on section 1 of the film (Fig. F9).

8. PERFORM THE FINAL POLISH

Insert the ferrule into the jig and lower it gently onto the moistened

polishing film.

Using the same medium pressure as in step 6, perform small

circles in a spirograph pattern as shown in (Fig. F10). Perform 25

circular strokes. Wipe the ferrule dry with a lint-free cloth and

inspect the ferrule end using the 100X microscope. The fiber

should be completely smooth and free of any scratches (Fig. F11).

If scratches are present in the fiber, perform an additional 3 to 5

strokes on an unused area of the film and inspect again. If

necessary a final lapping of 3 to 5 strokes can be performed.

Note: The final polishing film can be used to polish up to 4

ferrule ends. Be sure to use a fresh area of the polishing

film each time a new connector is to be polished.

Fig. F9

Fig. F10

Fig. F11