18

SECTION F

Polishing Process for Single-mode Connector Return

Loss >40dB

6. PERFORM THE 1.5 ϑm FINISH

Insert the ferrule into the jig and lower it gently onto the 1.5 ϑm

acetate.

Using medium pressure (equivalent to 1 lb of force), perform four

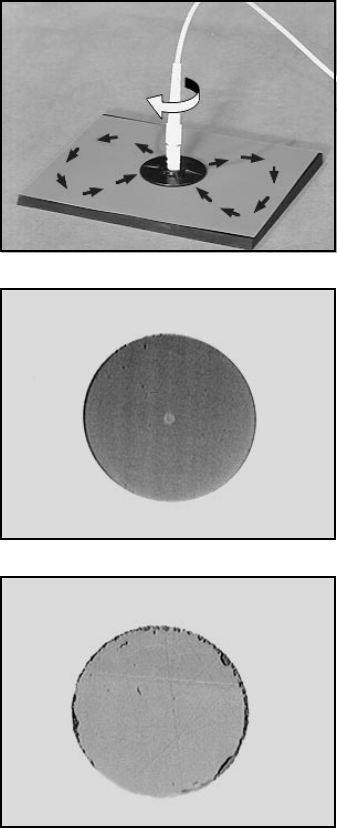

figure 8 strokes. Rotate the ferrule in the jig 180ϖ (Fig. F6) and

perform another four figure 8's. Continue to follow this sequence

rotating 180ϖ every 4 strokes until 6 sets of 4 figure 8's (24 total)

have been performed.

Note: Without rotating the ferrule the radius center may drift.

Rotating effectively eliminates this.

Clean the ferrule with a lint-free cloth moistened with isopropyl

alcohol and inspect the fiber using the 100X view scope. The

fiber should be completely smooth and all the epoxy removed as

in Fig. F7. If epoxy remains or scratches or rough edges are

present on the fiber as in Fig. F8, perform a few more figure 8

strokes on each 180ϖ orientation.

Note: If all of the epoxy was removed from the fiber during the

first step of polishing, the fiber surface may be heavily

scratched and pitted. If this is the case, perform another

set of figure 8's on each 180

ϖ

orientation and inspect again.

Note: The 1.5

ϑ

m diamond film can be cleaned with isopropyl

alcohol and blown dry for reuse. The sheet can be used to

polish up to 15 connectors.

Fig. F6

Fig. F7

Fig. F8