15

SECTION E

Standard Polishing Process for Single-mode and

Multimode Connectors

4. PREPARE TO PERFORM THE 1 ϑm FINISH

Using an isopropyl alcohol dampened lint-free cloth, clean the

ferrule, the polishing jig, and the 5 ϑm lapping acetate. Blow all

pieces dry with compressed air.

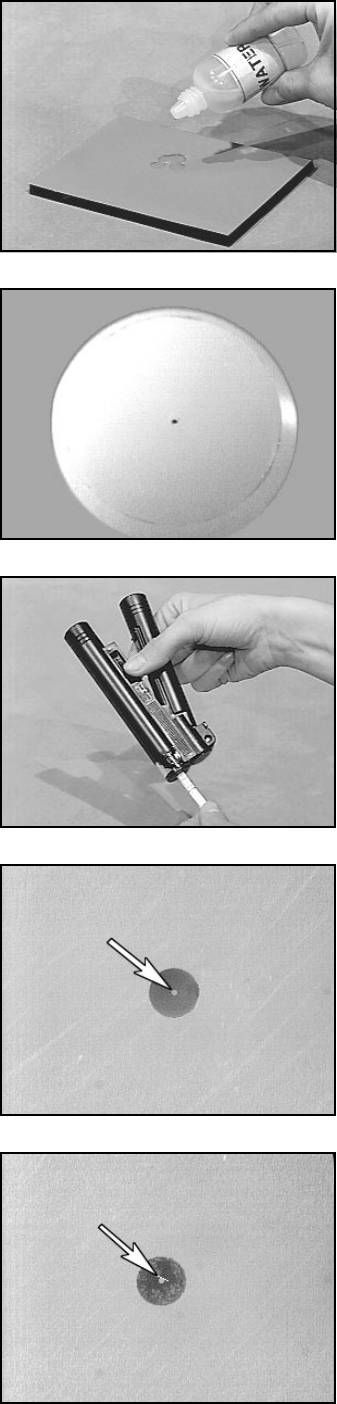

Clean a sheet of the green 1 ϑm lapping acetate and place it shiny

side down directly on top of the 5 ϑm acetate which remains on

the polishing pad. Place three to four drops of water on the 1 ϑm

acetate (Fig. E5).

5. PERFORMING THE 1 ϑm FINISH

Insert the ferrule into the jig and lower it gently on to the

moistened green 1 ϑm acetate.

Lightly polish until all the epoxy is removed (15 to 20 figure 8's).

Inspect with the jewelers loupe (Fig. E6).

Do not overuse the 1 ϑm lapping acetate. Always attempt to

polish on fresh areas of the acetate. After the entire surface of the

acetate has been used it can be cleaned with isopropyl alcohol

and reused to polish several more connectors and then discarded.

If deep scratches appear on the fiber, discard the 1 ϑm acetate at

that time.

6. FINAL INSPECTION

After polishing, remove the connector from the polishing jig, clean

the ferrule and insert it into the fiber view scope (Fig. E7). The

fiber should be free of epoxy and scratches and be flush with the

domed end of the ceramic ferrule (Fig. E8). If scratches or epoxy

are present (Fig. E9) clean the 1 ϑm acetate surface and repeat

step 5 with frequent inspections.

Fig. E5

Fig. E6

Fig. E7

Fig. E8

Fig. E9