10

Fig. C8

Fig. C9

Fig. C10

Fig. C11

SECTION C

Mounting

8. THREAD THE CONNECTOR ONTO THE FIBER

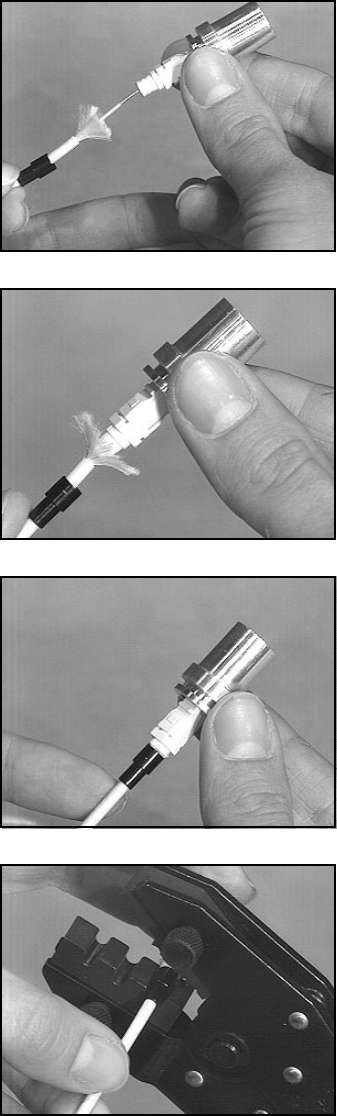

Slide the crimp ring up the cable within 1/2" (13 mm) of the end of

the jacket. Hold the cable in one hand directly behind the crimp

ring and hold the connector in the other hand. Rest your hands

on the table or against each other and carefully thread the

connector straight onto the fiber. Slowly rotate the connector

between thumb and forefinger in order to ease the funneling of the

fiber into the guide hole of the ferrule (Fig. C8). Carefully observe

that the fiber is moving through the ferrule while threading the

connector. This ensures that the fiber hasn't broken during the

mounting process.

While rotating the connector, maintain a continuous light inward

pressure in order to assist entry alignment. Slowly slide the

connector onto the fiber until the buffer seats at the base of the

ferrule. The Kevlar must flare around the backbone of the

connector (Fig. C9).

Once the buffer is seated, do not pull on the fiber. Keeping the

fiber forward will ensure that the epoxy does not deposit anywhere

inside the body of the connector. Hold the connector in place and

carefully slide the crimp ring up over the Kevlar until the ring is

seated with the back end of the connector (Fig. C10).

9. CRIMP THE RING ONTO THE CONNECTOR BACKBONE.

Make sure that the crimp ring is fully seated over the back of the

connector. Hold the connector in place with your forefinger and

middle finger. Be sure that the crimp cavity marked .190

completely covers the upper portion of the ring and crimp the ring

to the connector, securing the Kevlar (Fig. C11).

Next, crimp the smaller diameter of the crimp ring to retain the

cable's jacket. Use cavity .137 for 3.0 mm and .120 for 2.4 mm.

Be careful not to pinch the cable between the jaws.

10. EXAMINE THE EPOXY BEAD

The correct epoxy bead height at the fiber should be between 2 to

4 fiber diameters (0.10" to 0.020") above the ceramic tip. If this is

not the case, additional epoxy must be applied around the fiber

base to build the bead to the proper height. A short piece of

buffered fiber with about 1/4" (6 mm) of exposed fiber makes a

good applicator.

To apply: Carefully deposit epoxy on the end of the ferrule

through the opening in the load adapter using a short piece of

buffered fiber .

Important: The outside diameter of the ceramic ferrule must be

free of epoxy. Excess epoxy will adhere the load

adapter to the ferrule during the curing process.