46

Maintenance

TEST PROCEDURE

Step 1.

Set the thermostat high enough so that the unit will run

for at least 15 minutes, the maximum time that should

be required for the test. Let the unit operate enough

for the stack temperature to stabilize.

Step 2.

For your initial set of readings, set the Draft Regulator

so that there is .03 Water Column Draft in the smoke

pipe between the flue outlet and draft regulator.

A manometer must be used to properly set the draft to

.03” WC.

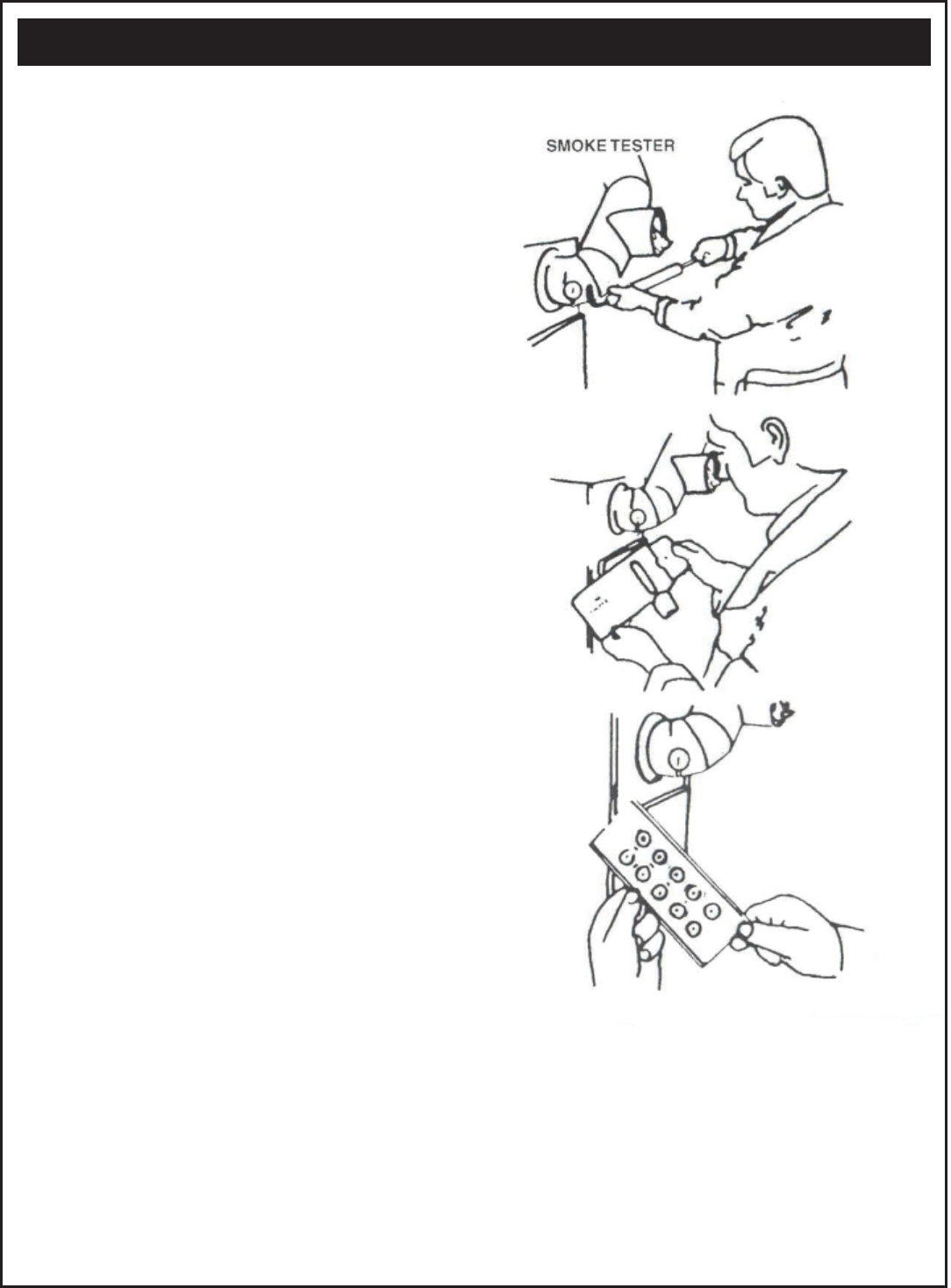

Step 3.

Insert the sampling tube of the CO

2

tester in the hole

that you have drilled adjacent to the stack

thermometer and find the percentage of CO

2

in the

sample of the products of combustion. Follow the

instructions of the manufacturer of the instrument you

are using.

Step 4.

Use efficiency finder chart or stack loss slide rule to

determine efficiency. Be sure to subtract room

temperature from stack thermometer reading and use

this net stack temperature for determining the

efficiency.

Step 5.

Insert end of smoke tester into same hole as was

used to test for CO

2

and perform the smoke test.

Step 6.

The filter paper from the smoke test, when compared

to the standard, must be determined and be found to

be satisfactory. It should never be greater than #2,

preferably #1 or zero, depending on local

requirements or your own service standard.

Repeat steps 3, 4, and 5 as needed, adjusting the air

shutter on the burner and draft regulator until you

obtain the highest possible efficiency. It is desirable to

have a high CO

2

reading and low stack temperature

with a minimum smoke reading.

FIG. 41

Questions? Visit www.yukon-eagle.com or call 1-800-358-0060