Maintenance

FURNACE BLOWER ADJUSTMENT

Set adjustable motor pulley so blower will give

approximately 80-90º F temperature rise through furnace.

After pulley has been adjusted check bolt as follows:

The belt is drawn tight during shipment. Therefore both

belt tension and sheave alignment must be rechecked by

the installer. This is done when the furnace is placed in

service.

Improper belt tension and pulley misalignment are the

major causes of furnace fan noise. It also causes failure of

belts and bearings.

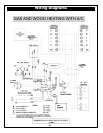

Sheave alignment is determined with a straight edge held

across outer face of fan sheave. The face of motor

sheave should be parallel to the straight edge at all points.

See Figs. 36-38

Proper belt tension is more difficult to determine

accurately. Too little tension will permit slippage causing

belt wear. It may cause noise or squealing when the motor

starts. Excessive tension increases motor load. It may

cause the oil film between shaft and bearing to fail. This,

in turn, causes the bearing to seize or burn out.

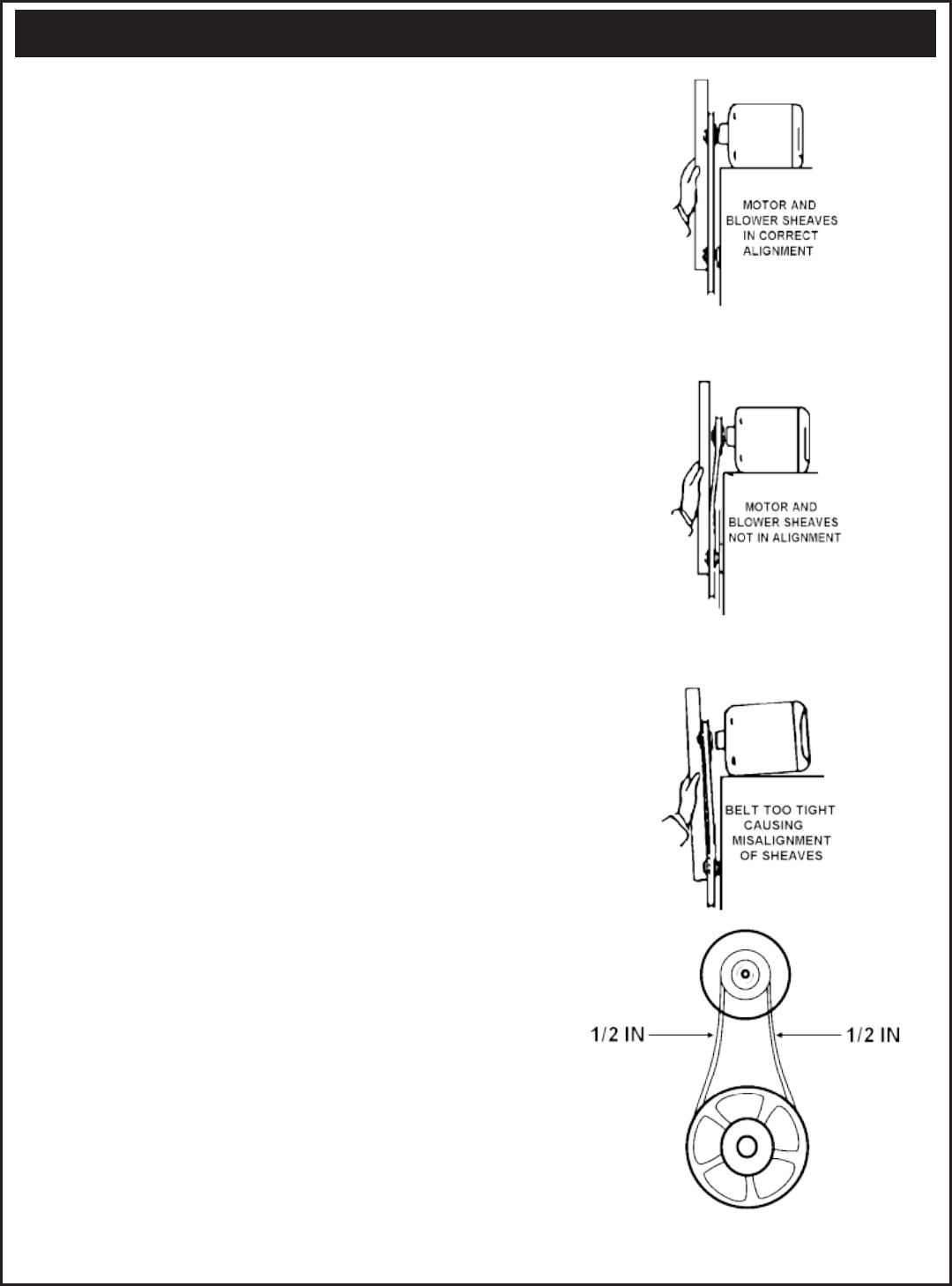

The proper belt tension is the minimum which will drive

the blower without slippage. This varies with sheave

diameter, fan size, and motor starting torque

characteristics. The practical belt tension can best be

determined by actual experience. When in doubt it is

better to have the belt too loose rather than too tight. Belt

tension can be judged by grasping the belt as shown. The

belt should be deflected approximately one inch, without

the motor moving, when moderate pressure is applied.

See Fig. 39

Questions? Visit www.yukon-eagle.com or call 1-800-358-0060

FIG. 39

FIG. 38

FIG. 37

FIG. 36

43