REFRIGERANT PIPING

GENERAL GUIDELINES

Many service problems can be avoided by taking adequate

precautions to provide an internally clean and dry system and

by using procedures and materials that conform with estab-

lished standards.

Useharddrawncopper tubingwhereno appreciableamountof

bending around pipes or other obstructions is necessary. Use

long radius ells wherever possible with one exception—short

radius ells for the traps in all suction risers. If soft copper is

used, care should be taken to avoid sharp bends which may

cause a restriction.

Pack fiber glass insulation and a sealing material such as per-

magum around refrigerant lines where they penetrate a wall to

reduce vibrations and to retain some flexibility.

Support all refrigerant lines at minimum intervals with suitable

hangers, brackets or clamps.

Braze all copper to copper joints with Silfos-5 or equivalent

brazing material. Do not use soft solder.

Insulate allsuction lines witha minimum of 1/2"ARMAFLEX or

equal. Liquid lines exposed to direct sunlight and/or high tem

-

peratures must also be insulated.

Never solder suction and liquid lines together. They can be

tapedtogetherforconvenience andsupportpurposes, butthey

must be completely insulated from each other.

Afilter-drierMUST beinstalled inthe liquidline ofeverysystem

to prevent dirt and moisture from damaging the system. A

properly-sized filter-drier is shipped with each condensing unit

forfieldinstallationnear theevaporatorcoil. Thefilter-drierand

is taped to the top of the compressor.

NOTE: Installing a filter-drier does not eliminate the need for

the proper evacuation of a system before it is

charged.

A moisture indicating sight-glass may be field installed in the

liquid line(s) between the filter-drier and the evaporator coil.

The moisture indicating sight-glass can be used to check for

excess moisture in the system or used as a visual means to

verify refrigerant charge.

LINE SIZING

When sizing refrigerant lines for a split-system air conditioner,

check the following:

1. Suction line pressure drop due to friction

2. Liquid line pressure drop due to friction

3. Suction line velocity for oil return, and

4. Liquid line pressure drop due to static head.

NOTE: Never base refrigerant line sizes on the O.D. of the

suction and liquid connections on the unit.

Tables 4and 5 list friction losses for both the suctionand liquid

lines on the system. Table 6 shows the amount of refrigerant

charge required per foot of refrigerant line.

Whentheevaporatorcoilisbelowthecondensingunit,thesuc-

tion linemust be sizedfor both pressuredrop andfor oil return.

For certain piping arrangements, different suction line sizes

may have to be used. The velocity of the suction gas must al

-

ways be great enough to carry oil back to the compressor.

When the condensing unit is below the evaporator coil, the liq

-

uidline mustbe designedfor thepressure dropdue toboth fric

-

tion lossand vertical rise. Ifthe total pressuredrop exceeds 40

psi, some refrigerant may flash before it reaches the thermal

expansion valve. This flashing will not only cause erratic valve

operation and poor system performance, but could also dam

-

age the expansion valve.

SERVICE VALVES

These condensing units have service valves on both the com

-

pressor suction connection and the liquid line leaving the con

-

denser coil.

The liquid and suction lineservice valves are shipped from the

factoryfront-seatedand closedwith thevalvestem inthe maxi

-

mum clockwise position.

Bothoftheservice valveshavea1/4" maleflareaccessport for

evacuating, charging and pressure checking the system.

NOTE: Never remove a cap from an access port unless the

valve is fully back-seated with its valve stem in the

maximum counter-clockwise position because the re

-

frigerant charge will be lost. ALWAYS USE A RE

-

FRIGERATION VALVE WRENCH TO OPEN AND

CLOSE THESE SERVICE VALVES.

035-15407-002-B-0404

Unitary Products Group 7

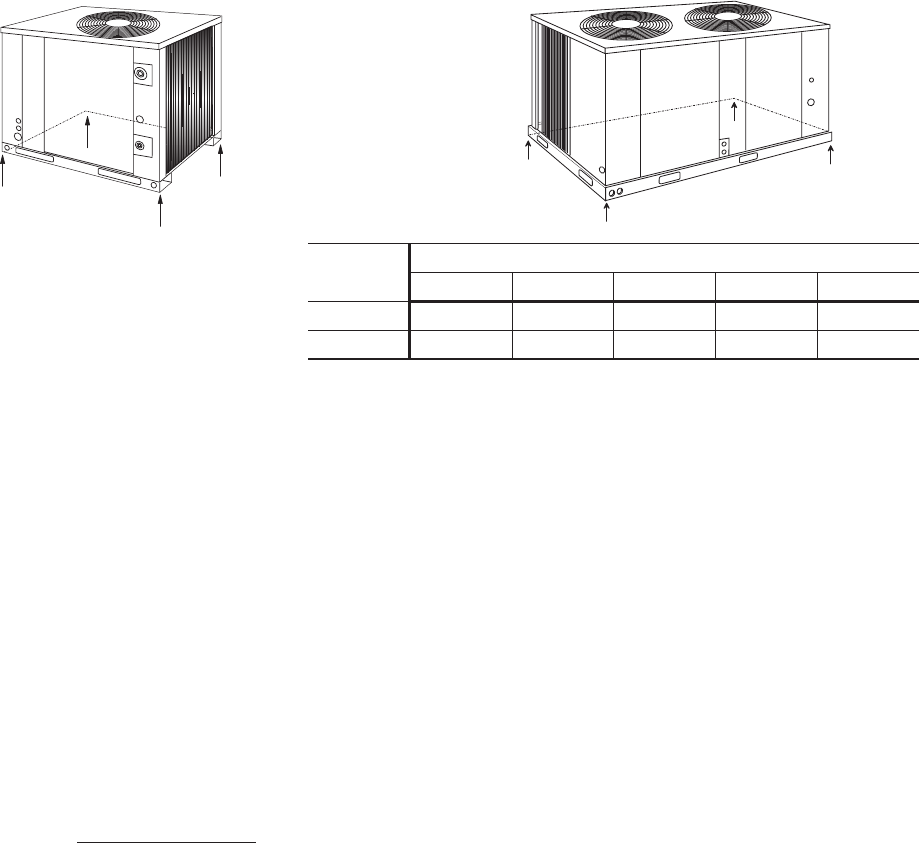

FIG. 6 - FOUR POINT LOADS

)

*

+

,

HCE090

)

,

+

*

HCE120 & 150

UNIT

4- POINT LOAD (LBS)

TOTAL A B C D

120 430 90 114 127 99

150 510 111 152 143 104