(29 feet x 8.0 psi/100 feet)

.............................................

2.3 psi

7 feet of 1-3/8" OD, type “L” copper tubing (horizontal)

(7 feet x 2.8 psi/100 feet)

...............................................

0.2 psi

Fitting*

....................................................................................

0.5 psi

Vapor Line Pressure Drop = 3.0 psi

*

Determinethepressuredropofthefittingsforeachinstallation- DONOTusetheestimated

values as shown in the above examples.

°

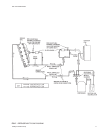

SERVICE VALVES

EXTENDING THE SERVICE PORTS

1. Loosen the screws securing the service ports in shipping

position. (See FIG 6).

2. Push the service ports through the corner post.

3. Tighten thescrews to secure theservice portsfor installation.

INSTALLATION

Since the condensing units are shipped with a holding charge

of Refrigerant-22, they can be checked for a refrigerant leak by

depressing the stem on either of the service ports that extend

through the cabinet. As soon as some internal pressure is re

-

lieved release the stem. DO NOT release the entire holding

charge.

CAUTION: When making a braze connection, wrap a wet rag

around all tubinginside the unit toprevent damage

to the other components.

Dry nitrogen should always be supplied through a

connection while it is being brazed or unbrazed

because the temperature required to make or

break a brazed joint is sufficiently high to cause

oxidation of the copper unless an inert atmos

-

phere is provided. The flow of nitrogen should be

continued until the joint has cooled.

WARNING: The dry nitrogen must always be supplied through

a pressure regulating valve.

Make sure the refrigerant in the line has been recovered

and that the liquid service valve on the unit is front-seated

and closed. The valve stem should be turned to its maxi-

mum clockwise position.

Drill a small hole throughthe disc before unbrazing it to per-

mit a flow of dry nitrogen through the connection while it is

being unbrazed.

WARNING: This hole is also required to prevent the internal

pressure from building up as the disc is being un

-

brazed and from blowing the disc off.

This warning applies to any disc being removed

from a service valve, coil connection, etc.

Remove the cap from the 1/4" access port on the liquid line stop

valve.

Connect a supply of dry nitrogen to this access port.

Unbraze the copper disc from the liquid connection while

maintaining a minimum flow of dry nitrogen through the

connection.

Burnish the external surfaces of the liquid connection on

the outdoor unit and the end of the field-supplied piping be

-

ing used for the liquid line.

NOTE:

2. Carefully clean the internal surfaces of the above. Any par

-

ticles left on these surfaces may lead to a future system

malfunction.

8 Unitary Products Group

1

All horizontal vapor lines should be level since the refrigerant flows in both directions.

2

Allvaporlineswithaverticalriseexceeding50feetshouldhaveanintermediatetrap.Small

radiustrapswillprovidedrainagepointsfortheoilwhichisintheriserwhenthecircuitis

deactivated.Whenthecircuitisreactivated,theoilwillbereturnedtothecompressormore

quickly and in smaller slugs.

3

Everyvaporrisergreaterthan5feetinheightshouldhaveasmallradiustrapatthebottom.

4

BasedonRefrigerant-22atthenominalcoolingcapacityofthesystem,avaportemperature

of40°Fandaliquidtemperatureof105°F.Sincerefrigerantflowrateswillbealittlelowerat

thenominalheatingcapacityofeachsystem,vaporlinefrictionlossshouldalwaysbebased

on cooling operation.

5

Althoughvaporlinesshouldbesizedforafrictionlossequivalenttoa2°Fchangeinsaturation

temperature (or approximately 3 psi), sizing the lines for the proper return of oil is more

important.

6

These friction losses do not include any allowance for fittings. Only use a 1-1/8" riser when

the indoor unit is above the outdoor unit.

TABLE 5

1

Charges are based on 40°F suction temperature and 105°F liquid temperature.

2

Type “L” copper tubing.

TABLE 6