107272-UIM-B-1105

4 Unitary Products Group

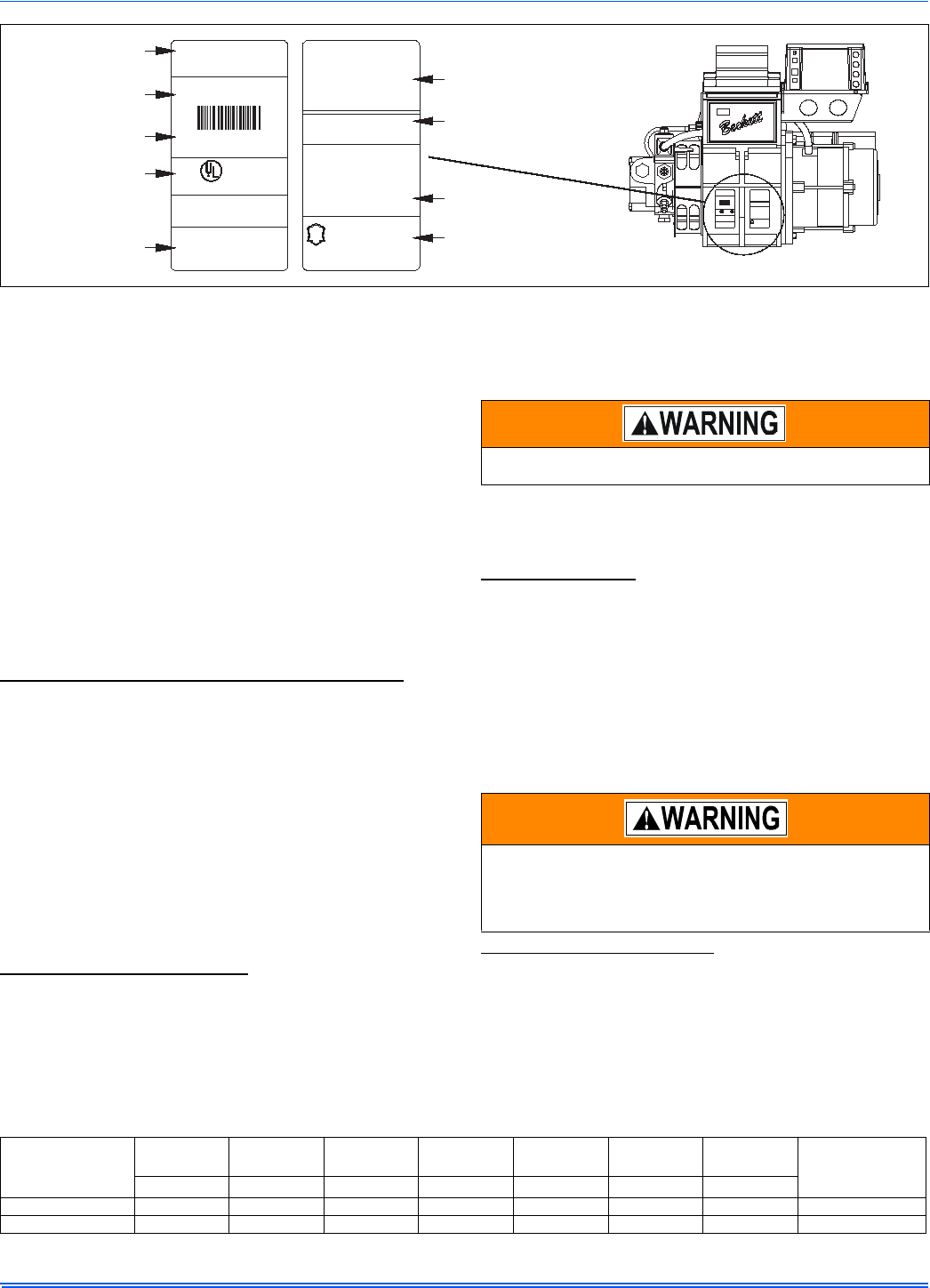

CHECK CERTIFICATIONS / APPROVALS

• Underwriters Laboratories has certified this burner to comply with

ANSI/UL 296 and has listed it for use with #1 or #2 fuel oil as

specified in ASTM D396. Low sulfur #1 and #2 fuel oils reduce

heat exchanger deposits with all burners compared to the stan-

dard fuels. Reduced deposits may extend the service interval for

cleaning and improve the efficiency of the appliance over time.

Low sulfur fuels reduce particulate and oxides of nitrogen emis-

sions as well. The Oil Heat Manufacturers’ Association recom-

mends these fuels as the preferred fuels for this burner.

• State and local approvals are shown on burner rating label (See

Figure 1).

• All oil burners must be installed in accordance with the regula-

tions of the latest revision of the National Fire Protection Associa-

tion Standard NFPA 31 and in complete accordance with all local

codes and authorities having jurisdiction. Regulation of these

authorities take precedence over the general instructions pro-

vided in this installation manual.

FURNACE LOCATION AND CLEARANCES

The furnace shall be located using the following guidelines:

1. The furnace should be located where the roof jack can be installed

without major modifications to the roof of the structure.

2. As centralized with the air distribution as possible.

3. Where there is access to fresh air particularly when the blend air

accessory will be installed.

4. Where it will not interfere with proper air circulation in the confined

space.

5. Where the outdoor section of the roof jack will not be blocked or

restricted. Refer to “VENT CLEARANCES” located in SECTION VI

of these instructions. These minimum clearances must be main-

tained throughout the installation.

6. Where the unit will be installed in a level position with no more than

1/4” (0.64 cm) slope side-to-side and front-to-back to provide a

proper roof jack connection and seal.

Installation in freezing temperatures:

1. Furnace shall be installed in an area where ventilation facilities

provide for safe limits of ambient temperature under normal oper-

ating conditions. Ambient temperatures below 32º F (0º C) may

result in the vent temperature falling below 260º F (127º C) at any

point in the vent pipe. Vent temperatures below 260º F (127º C)

will cause the flue products in the vent pipe to condense causing

the vent pipe to deteriorate rapidly.

2. Do not allow return air temperature to be below 55º F (13° C) for

extended periods. To do so may cause condensation to occur in

the main heat exchanger, leading to premature heat exchanger

failure.

3. If this furnace is installed in an unconditioned space and an

extended power failure occurs, there will be potential damage to

the internal components. Following a power failure situation, do

not operate the unit until inspection and repairs are performed.

Clearances for access:

Ample clearances should be provided to permit easy access to the unit.

The following minimum clearances are recommended:

1. Twenty-four (24) inches (61 cm) between the front of the furnace

and an adjacent wall or another appliance, when access is

required for servicing and cleaning.

2. Twenty-four (24) inches (61 cm) at the side where access is

required for passage to the front when servicing or for inspection

or replacement of flue/vent connections.

In all cases, accessibility clearances shall take precedence over clear-

ances for combustible materials where accessibility clearances are

greater.

Installation in a residential garage:

1. An oil-fired furnace for installation in a residential garage must be

installed so the burner(s) and the ignition source are located not

less than 18 inches (46 cm) above the floor, and the furnace must

be located or protected to avoid physical damage by vehicles.

FIGURE 1: Label Location

#1or#2fueloil

MP1192BJB3001R00

ApprovalJuly1,1988

ForusewithGroup1or2

primarysaftycontrols&

MadeintheU.S.A.

ApprovalJuly1,1988

Approval#BEC-88-01

StateFireMarshall

Comm.ofMass.-

CS

DEPT.

OFFICEOF

MARSHAL

FIRE

THESTATE

P

U

B

L

I

Y

T

F

A

E

AcceptedN.Y.C.MEA.213-83-E

Elyria,Ohio

000405-62736

SERIALNUMBER

R.W.BeckettCorp.

OILBURNERNO.PI-100001

LISTED

R

R

0.50-3.00GPH,120V/60HZ5.8A

2-3/4U

100PSI

1.0X80BDLVN

0.75-1.35GPH

F3

NOZZLE:

STCPLT:

HEAD:

BJB3001R00

FIRINGRNG:

PUMPPRS:

4ULTESTSPEC

5ULTESTSPEC

6ULTESTSPEC

7ULTESTSPEC

8ULTESTSPEC

9ULTESTSPEC

000405-62736

SeriesOilBurner

Model"AF"

AF65XNATC:

MFR'SSETTINGS

RWB

ELYRIA

OHIO U.S.A.

AcceptedN.Y.C.MEA.213-83-E

Comm.ofMass.-

StateFireMarshall

Approval#BEC-88-01

ApprovalJuly1,1988

FIRE

MARSHAL

E

DEPT.

CS

A

F

I

L

T

Y

U

P

THESTATE

OFFICEOF

B

020923-49038

026-37357-000

NOZZLE: 0.65X70ADLVNHLW

EVC201 R00

PUMPPRS: 100PSI

MFR'S SETTINGS

HEAD:

STCPLT:

FIRINGRNG:

ATC:

0.5-1.10GPH

F3

3-3/8U

AF36YHHS

R.W.BeckettCorp.

OILBURNER NO.PI-100001

Series OilBurner

MadeintheU.S.A.

primarysafetycontrols&

ForusewithGroup1or2

#1or#2fueloil

MP1192 EVC201 R00

Elyria,Ohio

LISTED

R

120V/60Hz5.8A

FiringRng:0.50-0.75GPH

020923-49038

SERIALNUMBER

Model "AFEVC"

R. W. Beckett

Manufacturer’s Settings

R. W. Beckett Specification

Number and Revision

Can be Customized by

Individual Specification

State and LocalApprovals

General Model

Information

Serial Number,

Including Date Code

Rating Information

Approval Agency

Symbols

Primary Group

and Fuel Oil

Installation in an ambient below 32ºF (0.0° C) could create a haz-

ard, resulting in damage, injury or death.

Check the rating plate and power supply to be sure that the electri-

cal characteristics match. All models use nominal 115 VAC, 1

Phase 60Hz power supply.

Furnace shall be installed so the electrical components are pro-

tected from water.

TABLE 1:

Unit Clearances to Combustibles

APPLICATION

TOP FRONT BACK SIDES

AIR INLET

PIPING

ROOF JACK

DUCT

1

1. Approved Duct Connector must be used. Refer to Section II - Ductwork.

FLOOR/BOTTOM

In. (cm) In. (cm) In. (cm) In. (cm) In. (cm) In. (cm) In. (cm)

CLOSET 2 (5.08) 6 (15.24) 0 (0.0) 0 (0.0) 0 (0.0) 3 (7.62) 0 (0.0) 0 (0.0)

ALCOVE 2 (5.08) 24 (60.96) 0 (0.0) 0 (0.0) 0 (0.0) 3 (7.62) 0 (0.0) 0 (0.0)