107272-UIM-B-1105

Unitary Products Group 13

Follow information provided with the burner, the fuel pump, or the calcu-

lation below to determine pipe size and length.

L = Line Length in feet

H = Head in feet

Q = Firing rate in GPH

3/8” (0.95 cm) line L = (6 - 0.75 x H) / 0.0086 x Q)

1/2” (1.27 cm) line L = (6 - 0.75 x H) / (0.00218 x Q)

If tank is above the oil pump, then use the following calculation:

3/8” (0.95 cm) line L = (6 + 0.75 x H) / (0.0086 x Q)

1/2” (1.27 cm) line L = (6 + 0.75 x H) / (0.00218 x Q)

IMPORTANT: The recommended piping configuration is a single or two

pipe system that is inserted into the top of the tank as shown in Figure

17 or 18. The two pipe system should be used in applications where the

oil tank is considerably lower than the burner and the oil pump keeps

losing its prime. The oil line should never be connected to the bottom of

the oil tank if the oil tank is outdoors. Water in the bottom of the oil will

freeze in the winter causing the oil line to freeze.

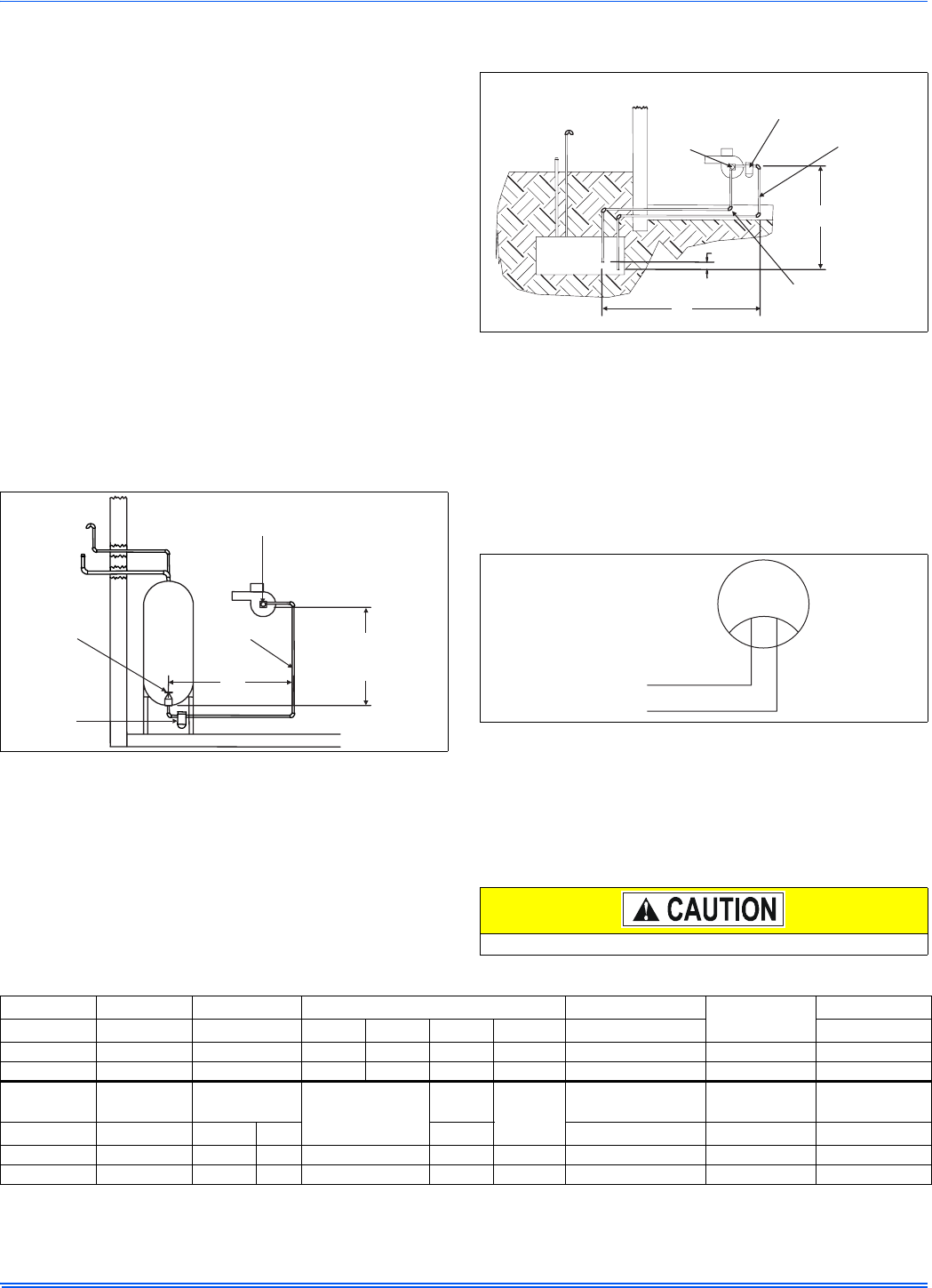

ONE PIPE SYSTEM

DO NOT INSTALL BY-PASS PLUG! Connect inlet line to pump inlet.

Start burner. Arrange primary burner control for continuous operation

during the purging. Place a clear plastic tube on bleed valve. Open

bleed valve 1 turn counterclock wise. Bleed until all air bubbles disap-

pear. Tighten bleed valve securely. Hurried bleeding will impair efficient

operation of unit. Refer to Figures 16 and 17.

TWO PIPE SYSTEM

Remove 1/16” (0.16 cm) pipe by-pass plug from plastic bag attached to

the unit. Remove 1/4” (0.635 cm) plug from return port. Insert by-pass

plug into the return port of the oil pump. The oil pump return port loca-

tion is shown in Figure 16.

Insert a 1/4” MPT x flare adaptor into the by-pass port and the inlet port.

Attach the return and inlet copper lines that go to the oil tank. Start the

burner. DO NOT open the bleed valve. The air in the oil lines will bleed

automatically.

The return line must terminate 3” to 4” above supply line in the oil tank.

Failure to do this may introduce air into the system and could result in

the loss of the prime. Refer to Figure 18.

SOLENOID WIRING

DISCONNECT THE POWER SUPPLY BEFORE WIRING TO PRE-

VENT ELECTRICAL SHOCK OR EQUIPMENT DAMAGE.

Lead wires on these devices are long enough to reach the junction box

on most burner installations. Refer to Figure 19.

NOTE: Check the burner manufacturer’s installation sheets for the cor-

rect solenoid wiring. All electrical wiring must be done in accordance

with the local codes.

NOTE: Solenoid power requirements: 115 VAC, 0.1 Amp, 60 Hz

SECTION V: ELECTRICAL POWER

Electrical Power Connections

Field wiring to the unit must be grounded. Electric wires that are field

installed shall conform to the temperature limitation for 63°F (35°C) rise

wire when installed in accordance with instructions. Refer to Table 8 in

these instructions for specific furnace electrical data.

Annual Fuel Utilization Efficiency (AFUE) numbers are determined in accordance with DOE Test procedures.

Wire size and over current protection must comply with the National Electrical Code (NFPA-70-latest edition) and all local codes.

The furnace shall be installed so that the electrical components are protected from water.

Rotation when facing shaft end.

FIGURE 17: One-Pipe System

Oil

Tank

Maximum

One Pipe (H)

Lift: 8 Ft

“R”

Inlet

Fuel Unit

Primary

Filter

Shut-Off

Valve

Fill

Pipe

Air

Vent

L=H+R

FIGURE 18: Two-Pipe System

FIGURE 19: Solenoid Wiring

Use copper conductors only.

Oil

Tank

Fill

Pipe

Air

Vent

Outside Tank Fuel Unit

Above Bottom of Tank

Fuel

Unit

Inlet

Primary

Filter

L=H+R

“R”

“H”

Use Protective Plastic

Tubing in Concrete or as

Local Codes Require

3”-4”

To Power

Control

Violet

White

Bypass

Solenoid

Valve

TABLE 8: Ratings & Physical / Electrical Data

Input Output Nominal Burner Air Temp. Rise

AFUE

Input Rate

MBH (kW) MBH (kW) CFM (cm) Amps HP RPM Rotation °F (°C) GPH (Liter / H)

66 (19.3) 53 (15.5) 1050 (29.7) 2.1 1/7 3450 CCW 45 - 75 (28 - 47) 80 0.50 (1.9)

84 (24.6) 67 (19.6) 1250 (35.4) 2.1 1/7 3450 CCW 45 - 75 (28 - 47) 80 0.65 (2.5)

Input

Max. Outlet

Air Temp

Blower

Max Over-current

Size (awg) @

75 ft. protect

Total

Unit

Min. Wire

One Way

Blower Size

DFAA

Operation Wgt.

DFAH

Operation Wgt.

MBH (kW) °F (°C) Hp Amps Amps In. (cm) LBS/Kg LBS/Kg

66 (19.3) 165 (74) 1/6 8.0 15 8.3 14 10 x 8 (25.4 x 20.3) 175/79.4 158/71.7

84 (24.6) 165 (74) 1/4 5.9 15 7.8 14 10 x 8 (25.4 x 20.3) 175/79.4 158/71.7