177820-YIM-A-0506

30 Unitary Products Group

The ASCD is initiated on unit start-up and on any com-

pressor reset or lock-out.

FLASH CODES

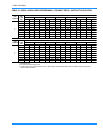

The UCB will initiate a flash code associated with

errors within the system. Refer to UNIT CONTROL

BOARD FLASH CODES Table 23.

RESET

Remove the call for cooling, by raising thermostat set-

ting higher than the conditioned space temperature.

This resets any pressure or freezestat flash codes.

HEATING SEQUENCE OF OPERATIONS

WITH OR WITHOUT ELECTRIC HEAT

When the thermostat calls for the first stage of heating,

the low voltage control circuit is completed between “R”

and “W1”. The 24vac signal is passed through the

UCB to the “Y” contact on the Defrost Control (DC)

assuring the reversing valve cannot be energized,

except during defrost. If the ASCD timer is satisfied the

UCB will energize compressor contactor M1.

If the compressor alone cannot satisfy the heating

requirements, a second stage call from the thermostat

completes the circuit between “R” and “W2”. This

24vac signal is passed through the UCB to the electric

heat section (if available). The total available kW of

electric heat will be energized on a call for “W2”.

DEFROST MODE

As mentioned earlier, the defrost control (DC) utilizes a

time/temperature defrost scheme. The following two

conditions must be met before the DC will enter a

defrost mode:

The defrost thermostat (SD) must be closed. This nor-

mally open thermostat is mounted on the liquid line and

is set to close at 28 ± 4°F.

Once the defrost thermostat closes, the defrost control

starts a run timer that must be satisfied before defrost

can begin. This is accumulated compressor run time.

The selection pin is factory set at 60 minutes, but is

field adjustable to 30, 60 or 90 minutes.

When the DC enters the defrost mode, it’s on-board

defrost relay is powered. This energizes the reversing

valve, de-energizes the condenser fan motor and ener-

gizes the unit’s optional electric heater. The DC

remains in defrost mode until either

of the following two

conditions is met:

1. The liquid line thermostat is open. It is set to open

at 55 ± 4°F.

2. The maximum defrost run time of 10 minutes is

met.

FORCED DEFROST

The processor on the defrost board is only energized

when the defrost sensor (DS) is closed.

To create a forced defrost:

1. The DS must either be closed or a jumper must be

placed across the DFS terminals on the board.

2. Place a jumper across the test pin terminals on the

board.

Depending on the selected defrost minimum run

time of 30, 60 or 90 minutes, the board will go into

defrost in 7.5, 15 or 22.5 seconds.

The DC will remain in defrost until the jumpers

across the DS and the test pin terminals are

removed.

Once the jumpers are removed, the board then ter-

minates defrost when the DS opens or a maximum

of 10 minutes after the test pin jumper is removed,

whichever comes first.

SAFETY CONTROLS

The control circuit includes the following safety con-

trols:

1. Temperature Limit Switch (TLS) - This control is

located inside the heater compartment and is set to

open at the temperature indicated in the Electric

Heat Limit Control Setting Table 21. It resets auto-

matically. The limit switch operates when a high

temperature condition, caused by inadequate sup-

ply air flow occurs, thus shutting down the heater

and energizing the blower.