177820-YIM-A-0506

26 Unitary Products Group

PHASING

Check for proper compressor rotation. If the blower or

compressors rotate in the wrong direction at start-up,

the electrical connection to the unit is misphased.

Change the incoming line connection phasing to obtain

proper rotation. (Scroll compressors operate in only

one direction. If the scroll is drawing low amperage,

has similar suction and discharge pressures, or pro-

ducing a high noise level, the scroll is misphased).

SUPPLY AIR BLOWERS

These blowers have either 3-speed direct drive motors,

or single speed motors equipped with a belt drive. Belt

drive units have a variable pitch motor pulley that

allows the blower speed to be adjusted.

CHECKING SUPPLY AIR CFM

The RPM of the supply air blower will depend on the

required CFM, the unit accessories or options and the

static resistances of both the supply and the return air

duct systems. With this information, the motor speed

tap (direct drive) or the motor pulley number of turns

open (belt drive) can be determined from the Blower

Performance Data Tables.

Note the following:

1. The supply air CFM must be within the limitations

shown in the Unit Application Data Table 1.

2. Pulleys can be adjusted in half turn increments.

3. The tension on the belt should be adjusted as

shown in the Belt Adjustment Figure 12.

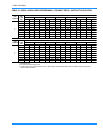

TABLE 20: STATIC RESISTANCES

1000 1200 1400 1600 1800 2000 2200 2400 2600

0.07 0.08 0.09 0.11 0.13 0.15 0.17 0.20 0.23

5-15KW 0.04 0.05 0.06 0.07 0.08 0.10 0.12 0.14 0.16

20-30KW 0.06 0.07 0.08 0.09 0.11 0.13 0.15 0.17 0.20

0.06 0.07 0.08 0.09 0.10 0.11 0.12 0.14 0.16

BOTTOM DUCT CONNECTIONS

1

ELECTRIC

HEATERS

1

RESISTANCE, IWG

CFM

DESCRIPTION

ECONOMIZER

1, 2

1. Deduct these resistance values from the available external static pressure shown in SUPPLY AIR BLOWER PERFORMANCE Tables.

2. The pressure through the economizer is greater for 100% outdoor air than for 100% return air. If the resistance of the return air

duct system is less than 0.25 IWG, the unit will deliver less CFM during full economizer operation.

Scroll compressors require proper rotation to

operate correctly. Do not change the internal

wiring to make the blower, condenser fans, or

compressor rotate correctly. Change the

incoming power to the main terminal block to

obtain proper rotation.

FIGURE 12 - BELT ADJUSTMENT