23

Hydraulic connections

The hydraulic connections of the water intake and outlet of

the chiller should be carried out respecting the intake and

outlet directions indicated at the front of the unit.

An iron (not galvanised) or copper tubing can be use, with

dimensions no lower than those indicated, and keeping in

mind the pressure drops of the indoor exchanger and of the

installation.

Pump dimensioning should be carried out considering a nomi-

nal flow that allows the ∆t of the project within the limits of the

unit: min. 3° C and max. 7° C. The head pressure of the pump

chosen must cover the pressure drops of the installation plus

the pressure drops of the chiller.

It is convenient that the tubing connection be carried out by

means of anti-vibratory couplings.

In all cases, a flow switch must be installed so as to avoid the

possibility of operation without water circulation, as well as a

water filter (both are obligatory for warrantee application).

In the water feedback tubing, an expansion vessel adequate

to the total volume of the water in the installation should also

be installed in the unit.

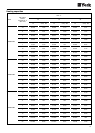

Chiller water volume is as follows:

During the winter season, with outdoor temperatures below

0° C, precautions should be taken to avoid the water from

freezing in the tubing networks and inside the inner chiller

exchanger.

The following solutions are usually applied:

a) Drain the circuit.

b) Fill the circuit with an antifreeze mixture (glycol).

c) Keep the circulator in constant operation.

Note: See hydraulic connections diagram.

WATER GAUGE

BUFFER TANK

(IF NECESSARY)

ISOLATOR

VALVE

SAFETY

VALVE

PURGER

AUTOMATIC FILLING

ASSEMBLY

FLOW SWITCH

THERMOMETERWATER GAUGE

DRAIN

EXPANSION

VESSEL

FLEXIBLE GASKET

FILTER

CIRCULATING

PUMP

FLEXIBLE GASKET

YLCC

YLCC-H

Size Litres

42 25

62 28

82 38.2

102 38.2

122 78.5

152 73.5

Hydraulic connections diagram