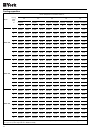

20

% Flow 70 80 90 100 110 120 130

5 3 1.5 0 -1 -2 -2.5

Correction in °C on real

temperature of coil

intake temperature

Correcting factors

Foul factors

Altitude factors

Correcting factors for real temperature of coil air intake at

flows other than nominal

Factors with water and glycol

Glycol can be used for antifreeze protection, or as brine for

operation at low temperatures. We recommend the use of

water and glycol when the discharge water temperature is

below +6° C. The “Solution with glycol/freezing point” table

gives the freezing point of water with glycol, and the “Recom-

mended glycol concentration” table shows the glycol concen-

tration needed, depending upon application.

Glycol contains anticorrosive and antifoam components that

favour circuit protection.

Solution with glycol/freezing point

A mixture of glycol and water has a freezing point below that

of pure water. Depending upon the concentration of glycol in

the solution, an even lower freezing point can be achieved

and this protects the circuit when the unit is off and ambient

temperature is low (below 0° C). This table indicates freezing

point in accordance with glycol concentration. This concen-

tration appears in % per weight.

Recommended glycol concentration

The glycol concentration in the water should be checked regu-

larly to ensure adequate protection of the chiller.

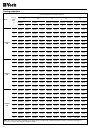

Correcting factors

Water flow correcting factors for ethylene glycol solu-

tions

Evaporator

Foul factor m

2

°C/kW

Capacity factor

Absorbed power

factor comp.

0.044 1.000 1.000

0.088 0.987 0.995

0.176 0.964 0.985

0.352 0.926 0.962

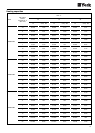

Altitude (m) Capacity factor

Absorbed power

factor comp.

0 1.000 1.000

600 0.987 1.010

1 200 0.973 1.020

1 800 0.958 1.029

2 400 0.943 1.038

LWT °C Glycol % per weight

6°C > LWT > 0°C 20

0°C > LWT > -5°C 30

Correcting factors

Water flow Pressure drop

20 1.035 1.16

30 1.075 1.27

Ethylene glycol

percentage by weight

(%)

00

10 -4

20 -10

30 -17

35 -20

40 -25

50 -37

% Glycol weight per weight Freezing point °C

Ethylene

glycol

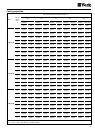

percentage

by weight

(%)

LWT

25 35 45

5 1.045 0.902 0.754

4 1.004 0.866 0.726

3 0.962 0.83 0.697

2 0.921 0.794 0.669

1 0.879 0.758 0.64

0 0.838 0.722 0.612

-1 0.795 0.681 0.574

-2 0.764 0.652 0.545

-3 0.734 0.623 0.515

-4 0.703 0.594 0.486

-5 0.673 0.565 0.457

20

30

Nominal capacity

correcting factors

Air temperature at

condenser intake (°C DB)