A

THE

TENSION

What

happens

now,

if

the

upper

tension

is

too

weak?

At

the

moment

the

lower

thread

should

he

drawn

from

the

bobbin

to

finish

the

stitch,

its

resistance

becomes

too

strong

in

relation

to

the

upper

tension.

Thus

the

upper

thread

in

unwound

before

the

lower

thread

is

drawn

into

the

material.

The

thread

take-up

lever

no

longer

meets

with

enough

resistance

from

the

upper

tension

to

enable

the

thread

to

cross

in

the

material

and

the

hewer

thread

remains

tretched

(Fig.

4

C).

What

happens,

if

the

upper

tension

is

too

tight?

At

the

moment

the

lower

thread

should

be

drawn

from

the

bobbin

to

finish

the

stitch,

its

resistance

is

too

weak

in

relation

to

the

upper

tension.

The

lower

thread

thus

un

winds

too

freely

and

does

not

offer

enough

resistance

to

the

pull

of

the

upper

thread.

The

upper

thread

withdraws

entirely

from

the

material

and

remains

stretched

on

top

of

it.

whilst

the

lower

thread

crosses

right

through

it

(Fig.

4

8).

It

is

most

important

that

the

functioning

of

the

upper

tension

and

how

it

should

be

adjusted

be

explained

in

detail

to

the

user.

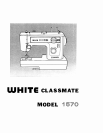

Fig.

5

Fig.

5

starts

by

showing

a

perfect

seam,

then

a

skipped

stitch

(A)

and

then

a

broken

thread

(B).

Skipped

stitches

are

caused

when,

for

one

reason

or

another,

the

point

of

the

hook

does

not

catch

the

loop

of

the

upper

thread.

On

all

lock-stitch

machines,

regardless

of

what

shuttle

systems

they

may

have,

the

upper

thread

has

to

form

the

loop

explained

in

detail

below.

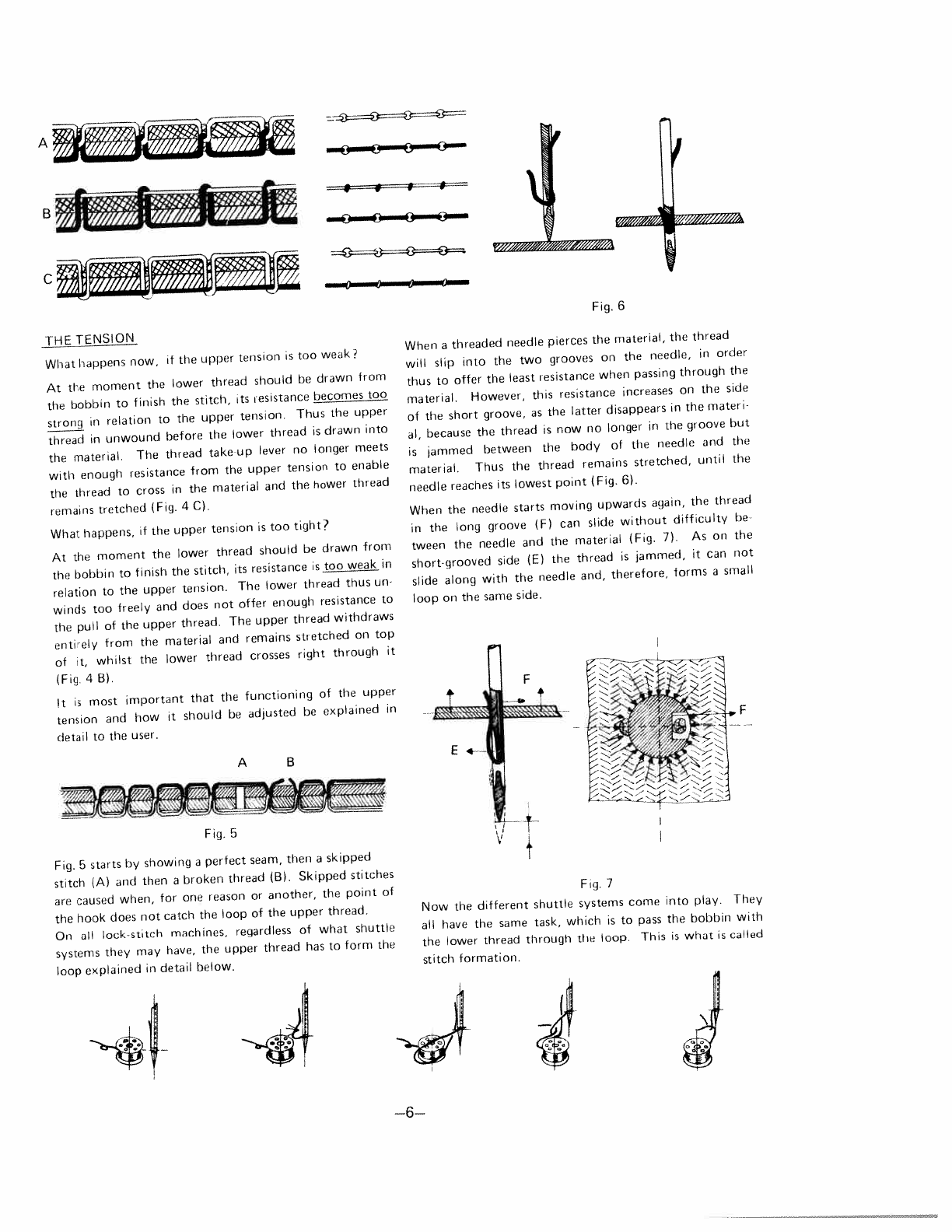

When

a

threaded

needle

pierces

the

material,

the

thread

will

slip

into

the

two

grooves

on

the

needle,

in

order

thus

to

offer

the

least

resistance

when

passing

through

the

material.

However,

this

resistance

increases

on

the

side

of

the

short

groove,

as

the

latter

disappears

in

the

materi

al,

because

the

thread

is

now

no

longer

in

the

groove

but

is

jammed

between

the

body

of

the

needle

and

the

material.

Thus

the

thread

remains

stretched,

until

the

needle

reaches

its

lowest

point

(Fig.

6>.

When

the

needle

starts

moving

upwards

again,

the

thread

in

the

long

groove

(F)

can

slide

without

difficulty

be

tween

the

needle

and

the

material

(Fig.

7).

As

on

the

short-grooved

side

(E)

the

thread

is

jammed,

it

can

not

slide

along

with

the

needle

and,

therefore,

forms

a

small

loop

on

the

same

side.

Fig.

7

Now

the

different

shuttle

systems

come

into

play.

They

all

have

the

same

task,

which

is

to

pass

the

bobbin

with

the

lower

thread

through

the

loop.

This

is

what

is

called

stitch

formation.

Fig.

6

P

F

V

4

1

—6-—