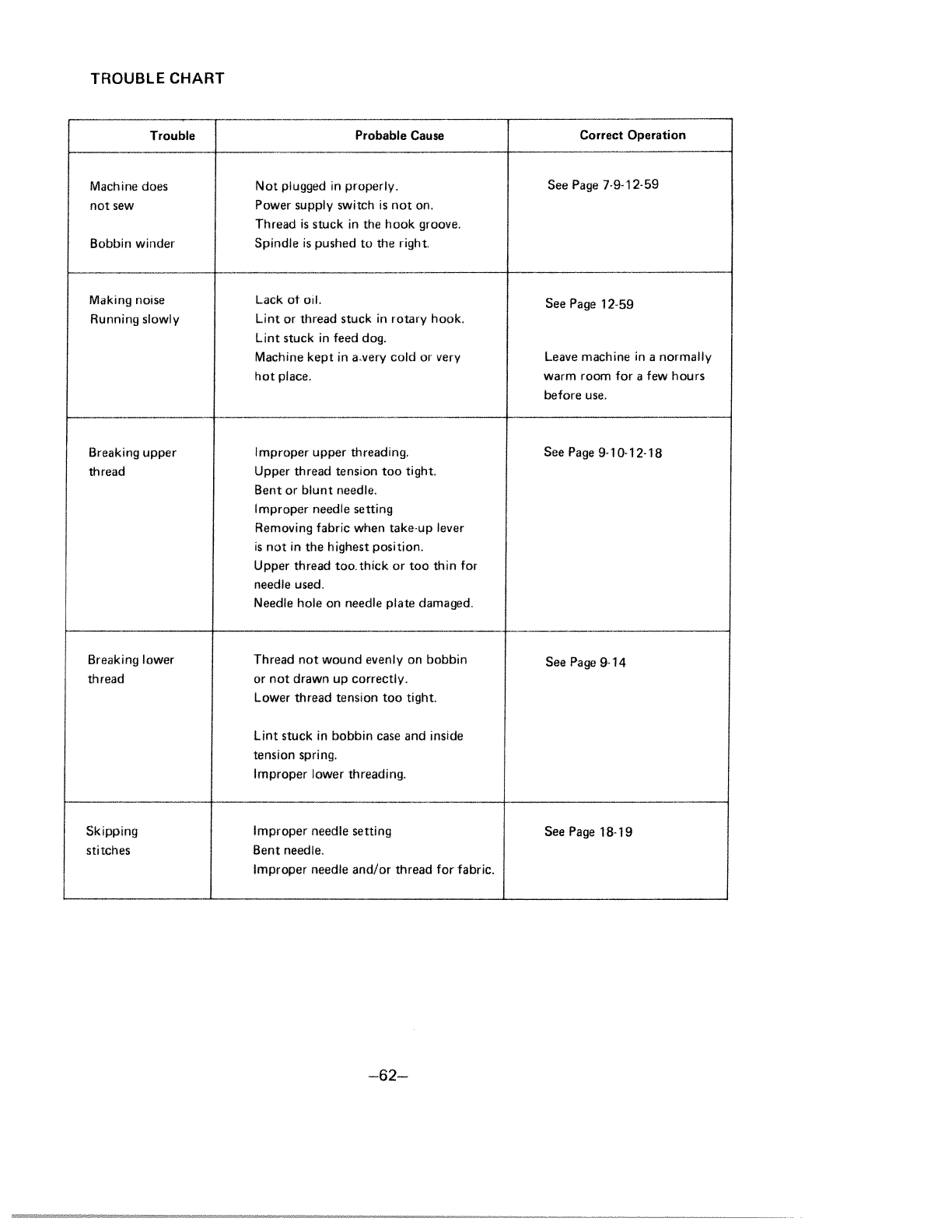

TROUBLE

CHART

Trouble

Probable

Cause

Correct

Operation

Machine

does

Not

plugged

in

properly.

See

Page

7-9-12-59

not

sew

Power

supply

switch

is

not

on.

Thread

is

stuck

in

the

hook

groove.

Bobbin

winder

Spindle

is

pushed

to

the

right.

Making noise

Lack

of

oil.

See

Page

12-59

Running

slowly

Lint

or

thread stuck

in

rotary

hook.

Lint

stuck

in

feed

dog.

Machine

kept

in

avery

cold

or

very

Leave

machine

in

a

normally

hot

place.

warm room

for

a

few

hours

before

use.

Breaking

upper

Improper upper

threading.

See

Page

9-10-12-18

thread

Upper

thread

tension

too

tight.

Bent or

blunt

needle.

Improper

needle

setting

Removing

fabric

when

take-up

lever

is

not

in

the

highest

position.

Upper

thread

toothick

or

too

thin

for

needle

used.

Needle

hole

on

needle

plate

damaged.

Breaking lower

Thread

not

wound

evenly

on

bobbin

See

Page

9-14

thread

or

not

drawn

up

correctly.

Lower

thread

tension

too

tight.

Lint

stuck

in

bobbin

case

and

inside

tension

spring.

Improper

lower

threading.

Skipping

Improper

needle

setting

See

Page

18-19

stitches

Bent

needle.

Improper

needle

and/or

thread

for

fabric.

—62—