THIS

INSTRUCTION

MANUAL

IS

DESIGNED

TO

GIVE

BASIC

INFORMATION,

TO

UNDERSTAND

THE

FUNCTIONS

OF

A

SEWING

MACHINE,

THREAD,

AND

NEEDLES.

For

sewing

a

normal

seam,

the

material

must

be

fed

regularly

for

the

formation

of

each

stitch.

The

feed

dog

does

the

conveying,

together

with

the

presser

bar

on

which

a

presser

foot

has

been

fastened.

Feed

Dog

The

task

of

the

feed

dog

is

to

move

the

cloth

on

for

a

certain

distance

after

each

stitch.

This

distance,

called

stitch

length,

can

be

accurately

adjusted

by

means

of

a

lever

or

a

knob,

which

acts

on

the

feed

mechanism.

The

feed

dog

is

equipped

with

small,

sharp

teeth.

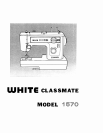

Fig.

1

shows

the

most

common

types

of

feed

dogs.

Fig.

2

A.

A

thread

is

left-twist

if,

when

held

horizontally,

the

individual

strands

slant

to

the

left

from

bottom

to

top.

B.

A

thread

is

right-twist

if,

when

held

horizontally,

the

individual

strands

slant

to

the

right

from

bottom

to

top.

F

Fig.

1

A.

The

“L”

shaped

feed

dog

is

the

oldest

type

and

common

to

sewing

machines

with

vibrating

shuttles.

It

has

the

disadvantage

that

it

does

not

feed

all

kinds

of

work,

such

as

f

ii.

collar

points,

evenly.

B.

The

“H”

shaped

feed

dog,

with

a

row

of

teeth

on

either

side

of

the

needle

plate

hole,

is

an

improve

ment

on

the

former,

but

does

not

feed

narrow

strips

or

hems

well.

C.

The

“M”

and

“0”

shaped

feed

dogs

guarantee

the

uniform

feed

of

any

kind

of

work

or

material.

Twist

of

the

Thread

Depending

on

the

kind

of

shuttle

used,

the

twist

of

the

thread

is

of

a

certain

importance.

If

thread

with

a

right-hand

twist

is

used,

it

will

unravel

slightly,

when

the

stitch

is

formed,

due

to

the

direction

of

rotation

of

the

shuttle.

This

naturally

reduces

the

tensile

strength

of

the

thread.

For

sewing,

the

question,

whether

left-

or

right-

hand

twist

is

used,

is

of

lesser

importance.

t

is

strongly

recommended,

however,

to

use

left-twist

thread

for

darning

with

fine

thread.

The

difference

between

the

two

kinds

of

twist

is

best

determined

in

the

following

manner:

tion.

1.

The

Needle:

Aim:

To

become

acquainted

with

the

structure

of

the

sewing

machine

needle

in

detail,

so

as

later

on

to

be

able

to

understand

better

how

the

stitch

is

formed.

Different

systems

and

sizes.

As

has

already

been

mentioned,

needles

have

existed

since

the

most

ancient

times.

They

were

made

of

thorns,

horn,

fish-bones,

gold

and

ivory.

The

first

steel

rteedles

were

made

in

Germany.

The

needle

with

the

eye

near

the

point

became

more

widely

used

with

the

introduction

of

the

Iockstitch

sewing

machine.

At

first,

each

manufacturer

used

a

needle

which

could

only

be

used

on

his

own

models.

The

differ

ent

kinds

of

needles

have

since

been

standardized

by

an

International

Agreement,

Needle

Systems

There

exist

approximately

2000

rliffer

ent

types

of

needles,

amongst

which

system

705

(U.S.A.:

style

15

x

1)

is

the

most

frequently

used

for

household

sewing

machines.

This

needle

is

also

used

for

the

ELNA!

WHITE

and

is

described

below

in

detail:

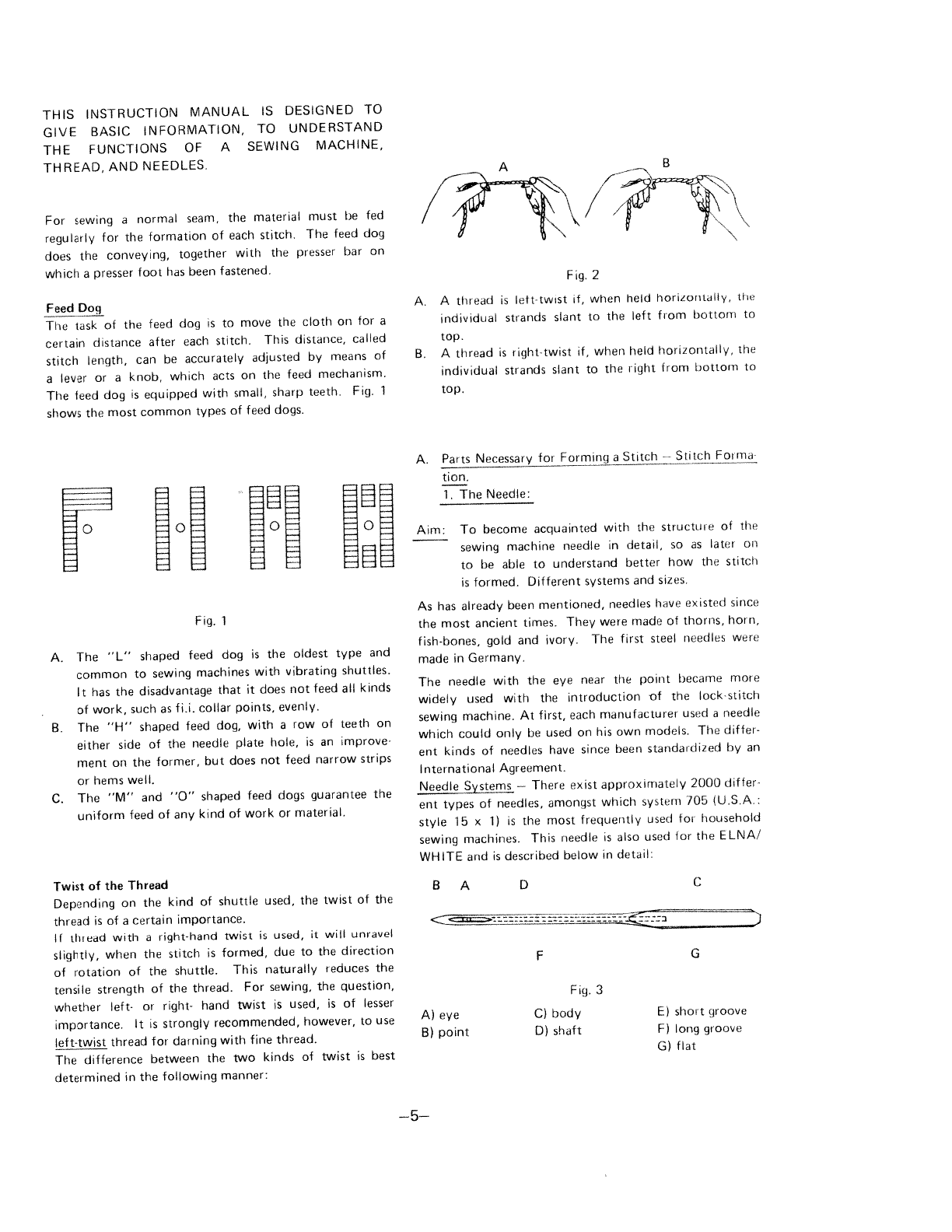

S

A

D

A)

eye

C)

body

E)

short

groove

B)

point

0)

shaft

F)

long

groove

G)

flat

A

B

A.

Parts

Necessary

for

Forming

a

Stitch

-—

Stitch

Forma

C

F

G

Fig.

3

—5—