TURN-AROUND

BUTTONHOLES

It

is

possible

to

make

small

and

dainty

but

tonholes

if

you

desire

or

repair

damaged

but

tonholes.

This

entails

a

slight

shifting

of

the

cloth

but

with

some

practice,

good

buttonholes

can

be

achieved.

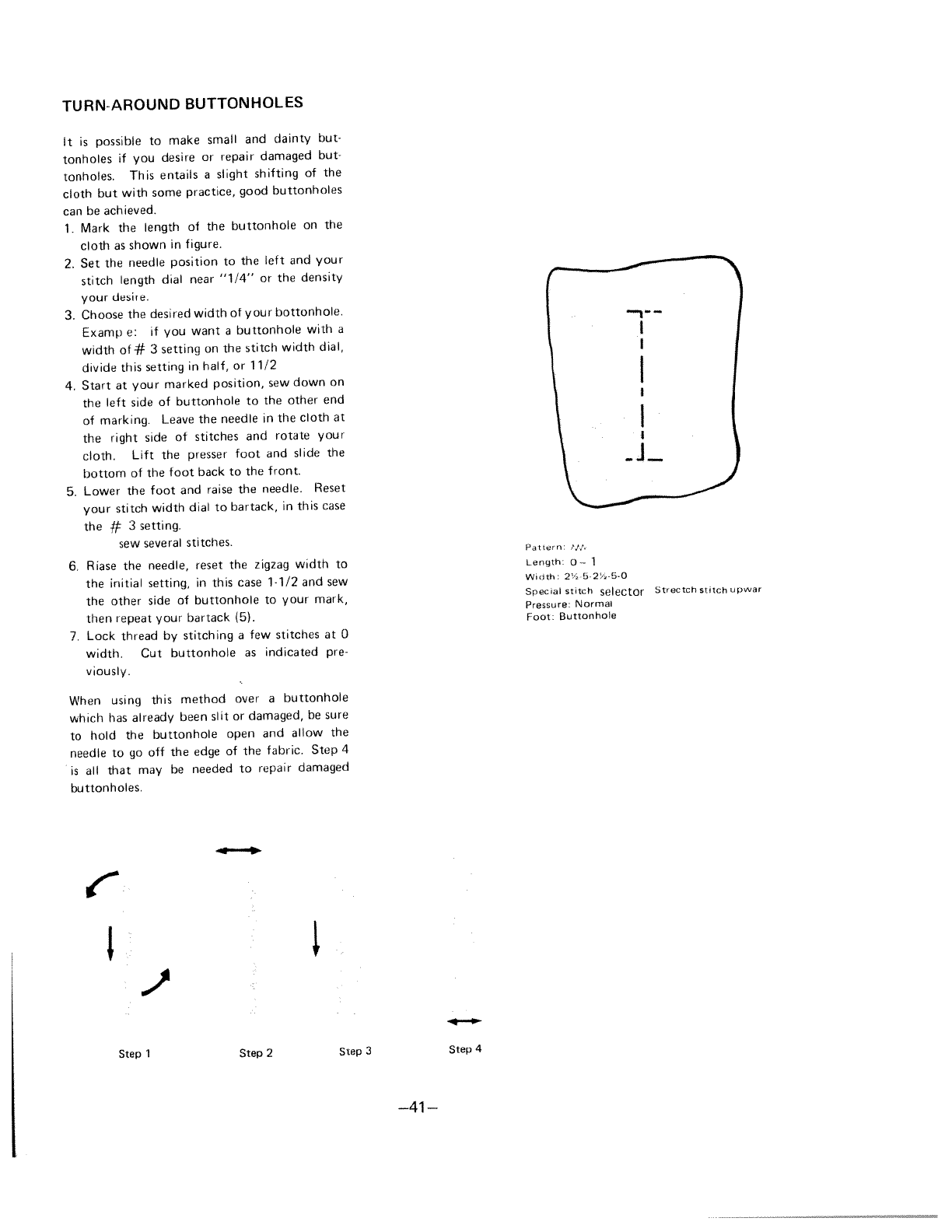

1.

Mark

the

length

of

the

buttonhole

on

the

cloth

as

shown

in

figure.

2.

Set

the

needle

position

to

the

left

and

your

stitch

length

dial

near

“1/4”

or

the

density

your

desire.

3.

Choose

the

desired

width

of

your

buttonhole.

Examp

e:

if

you

want

a

buttonhole

with

a

width

of#

3

setting

on

the

stitch

width

dial,

divide

this

setting

in

half,

or

11/2

4.

Start

at

your

marked

position,

sew

down

on

the

left

side

of

buttonhole

to

the

other

end

of

marking.

Leave

the

needle

in

the

cloth

at

the

right

side

of

stitches

and

rotate

your

cloth.

Lift

the

presser

foot

and

slide

the

bottom

of

the

foot

back

to

the

front.

5.

Lower

the

foot

and

raise

the

needle.

Reset

your

stitch

width

dial

to

bartack,

in

this

case

the

if

3

setting.

sew

several

stitches.

6.

Riase

the

needle,

reset

the

zigzag

width

to

the

initial

setting,

in

this

case

1-1/2

and

sew

the

other

side

of

buttonhole

to

your

mark,

then

repeat

your

bartack

(5).

7.

Lock

thread

by

stitching

a

few

stitches

at

0

width.

Cut

buttonhole

as

indicated

pre

viously.

When

using

this

method

over

a

buttonhole

which

has

already

been

slit

or

damaged,

be

sure

to

hold

the

buttonhole

open

and

allow

the

needle

to

go

off

the

edge

of

the

fabric.

Step

4

is

all

that

may

be

needed

to

repair

damaged

buttonholes.

Step

1

Step

2

Step

3

Pdirerr,

“i/,

Length:

0—

1

Width:

2-b-2.-5-O

Special

stitch

selector

Strectch

stitch

pwar

Pressure:

Normel

Foot:

Buttonho’e

4

-1-

I

Step

4

—41—