Installing in a casement window

to be fastened to the jamb. If the window cannot

open far enough (more than 15% inches) for the

cabinet to clear the window, remove the window

entirely by drilling out the rivets. Bolts can serve

as the pivots in the future.

NOTE: Open the window the maximum amount

To avoid the crank handle and window clearance

to allow for clearance of the cabinet. The crank

handle should be removed to allow the platform

problems, the unit can be installed in a stationary

sash section. However, the horizontal mullion

and the 2 glass panels must be removed before

installation.

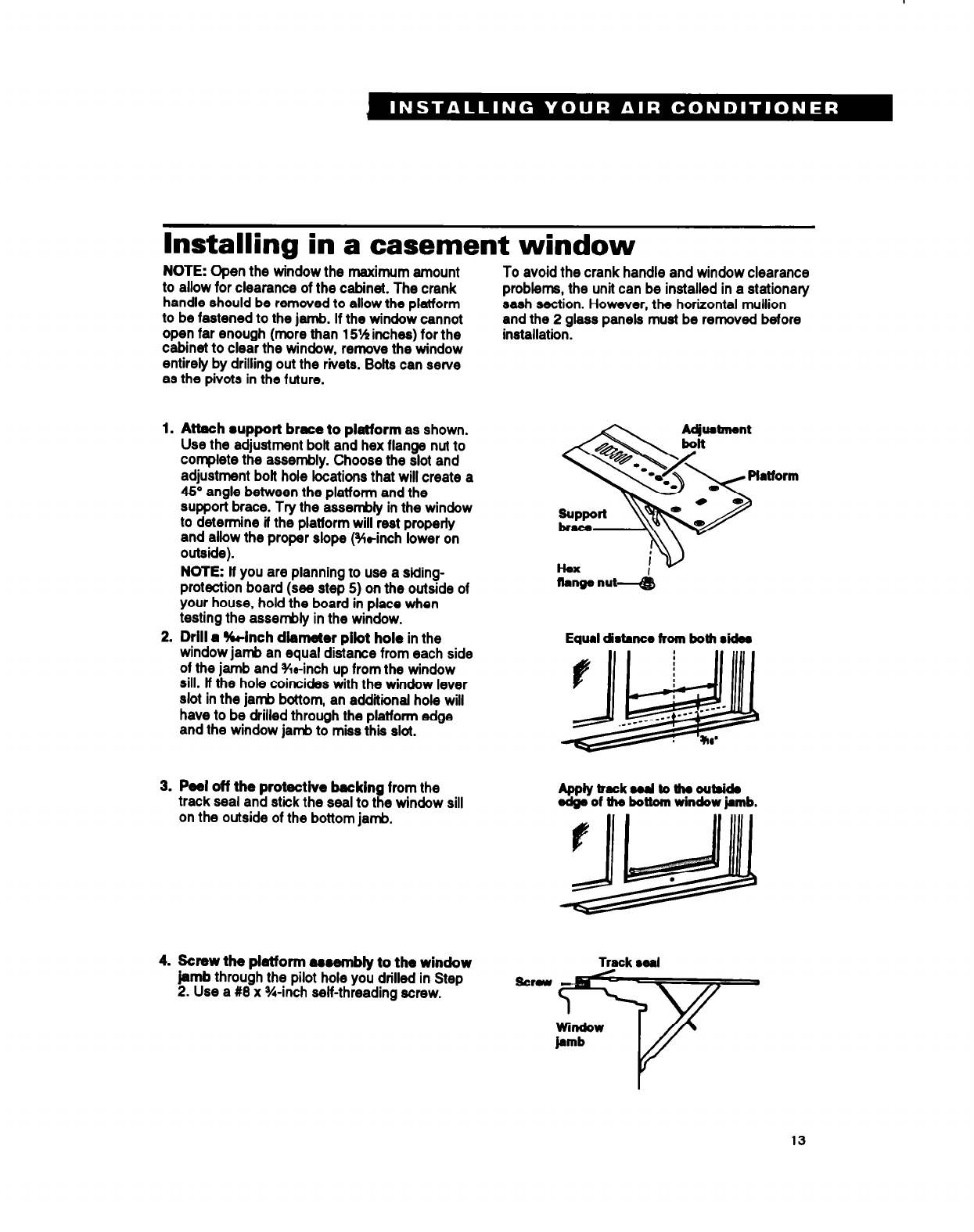

1. Attech support brace to platform as shown.

Use the adjustment bolt and hex flangs nut to

complete the assembly. Choose the slot and

adjustment bolt hole locations that will create a

45’ angle between the platform and the

support brace. Try the assembly in the window

to determine if the platform will rest properly

and allow the proper elope (?&inch lower on

outside).

NOTE: lf you are planning to use a skfing-

protection board (see step 5) on the outside of

your house, hold the board in place when

testing the assembly in the window.

2. Drill a Wclnch diameter pikt hole in the

window jamb an equal distance from each side

of the jamb and %-inch up from the window

sill. lf the hole coincides with the window lever

slot in the jamb bottom, an additional hole will

have to be drilled through the platform edge

and the window jamb to miss this slot.

3. Peel off the protective backing from the

track seal and stick the seal to the window sill

on the outside of the bottom jamb.

Equal df~tance from both

l

ickr

Appiytmcksuitotboouteido

dg~ of UM bottom

window jamb.

4.

Screw the pletform assembly to the window

jamb through the pilot hole you drilled in Step

2. Use a #8 x %-inch self-threading screw.

Track seal

-

13