12

GAS INSTRUCTIONS

Gas supply

Shut off

Locking shut off

Inside wall

Outside wall

Quick

disconnect

3

/

8

" Pipe

nipple

1

/

2

" Pipe

nipple

Do Not Use

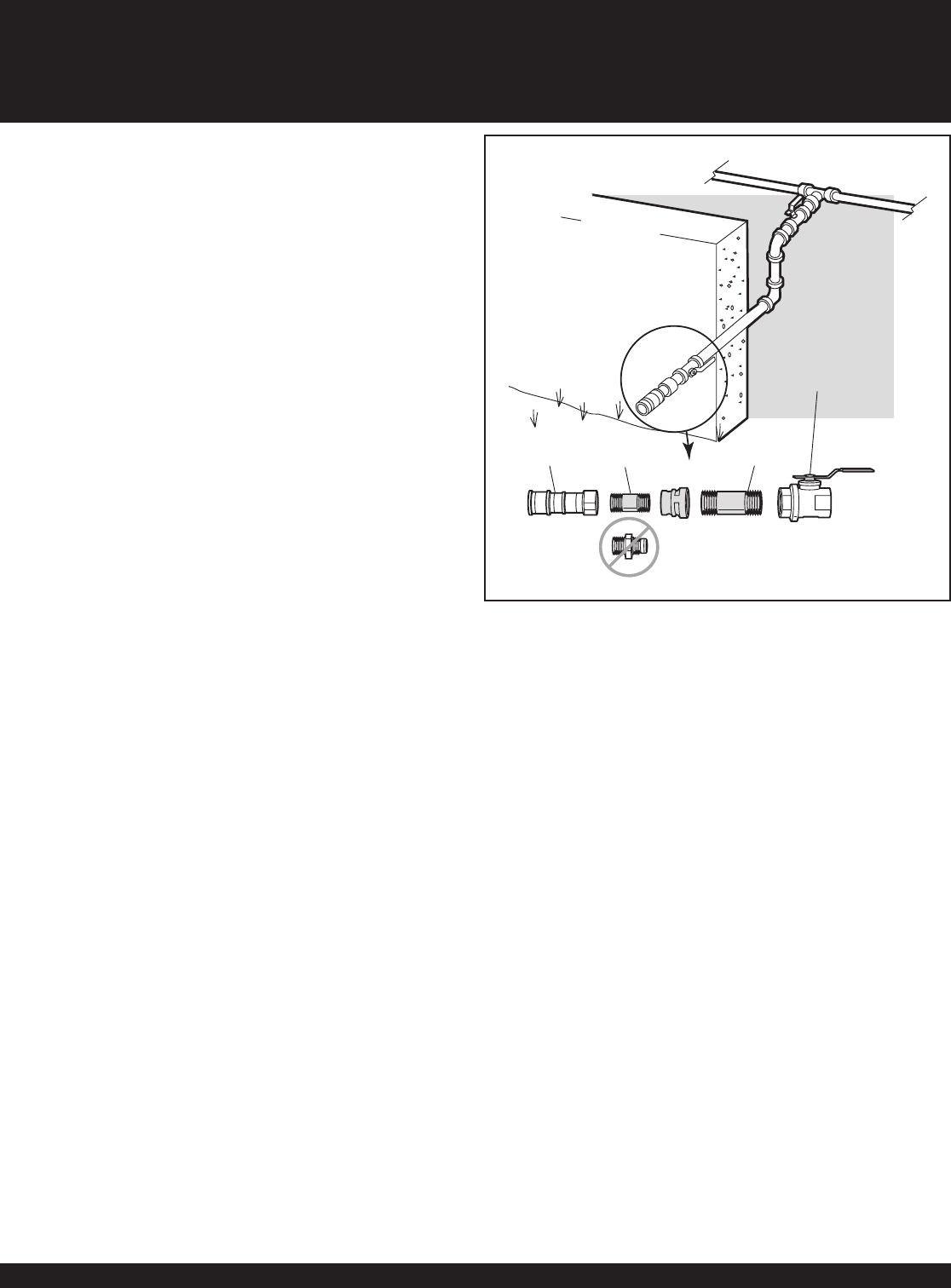

This is a typical installation

of a Weber

®

natural gas

fireplace. Local codes may

require different

installations.

INSTALL GAS SUPPLY

General Specifi cations for Piping

Note - Contact your local municipality for building codes regulating

outdoor gas fi replace installations.

• Refer to AS5601 gas installations for piping and hose requirements.

• Refer to AS5601/AG 601, local authority, gas, electric, and other

relevant statutory regulations for use and installation.

• WE RECOMMEND THAT THIS INSTALLATION BE DONE BY A

PROFESSIONAL.

Some of the following are general requirements taken from the latest

edition of the National Fuel Gas Code: ANSI Z 223.1/NFPA 54, or CAN/

CGA-B149.1, see Natural Gas and Propane Installation Code for complete

specifi cations.

• This fi replace is designed to operate at 4 inches of water column

pressure (.2526 psi).

• The maximum inlet gas pressure for this fi replace is 7 inches of water

column pressure.

• A manual shut-off valve must be installed outdoors, immediately ahead of

the quick disconnect.

• An additional manual shut-off valve indoors should be installed in the

branch fuel line in an accessible location near the supply line.

• The quick disconnect connects to a 3/8 inch NPT thread from the gas

source. The quick disconnect fi tting is a hand-operated device that

automatically shuts OFF the fl ow of gas from the source when the

fi replace is disconnected.

• The quick disconnect fi tting can be installed horizontally, or pointing

downward. Installing the fi tting with the open end pointing upward can

result in collecting water and debris.

• The dust covers (supplied plastic plugs) help keep the open ends of the

quick disconnect fi tting clean while disconnected.

• Pipe compound should be used which is resistant to the action of natural

gas when connections are made.

• The outdoor connector must be fi rmly attached to rigid, permanent

construction.

ƽ WARNING: Do not route the 10 foot hose under a

deck. The hose must be visible.

Gas Line Piping

• If the length of the line required does not exceed 50 feet, use a 5/8" O.D.

tube. One size larger should be used for lengths greater than 50 feet.

• Gas piping may be copper tubing, type K or L; polyethylene plastic tube,

with a minimum wall thickness of .062 inch; or standard weight (schedule

40) steel or wrought iron pipe.

• Copper tubing must be tin-lined if the gas contains more than 0.3 grams

of hydrogen sulfi de per 100 cubic feet of gas.

• Plastic tubing is suitable only for outdoor, underground use.

• Gas piping in contact with earth, or any other material which may corrode

the piping, must be protected against corrosion in an approved manner.

• Underground piping must have a minimum of 18" cover.

• Installation and repair should be done by a qualifi ed service person.

The fi replace should be inspected before use and at least annually by

a qualifi ed service person. More frequent cleaning may be required

as necessary. It is imperative that control compartment, burners and

circulating air passageways of the fi replace be kept clean.

Test Connections

All connections and joints must be thoroughly tested for leaks in accordance

with local codes and all listed procedures in the latest edition of the National

Fuel Gas Code: ANSI Z 223.1/NFPA 54, or CAN/CGA-B149.1.