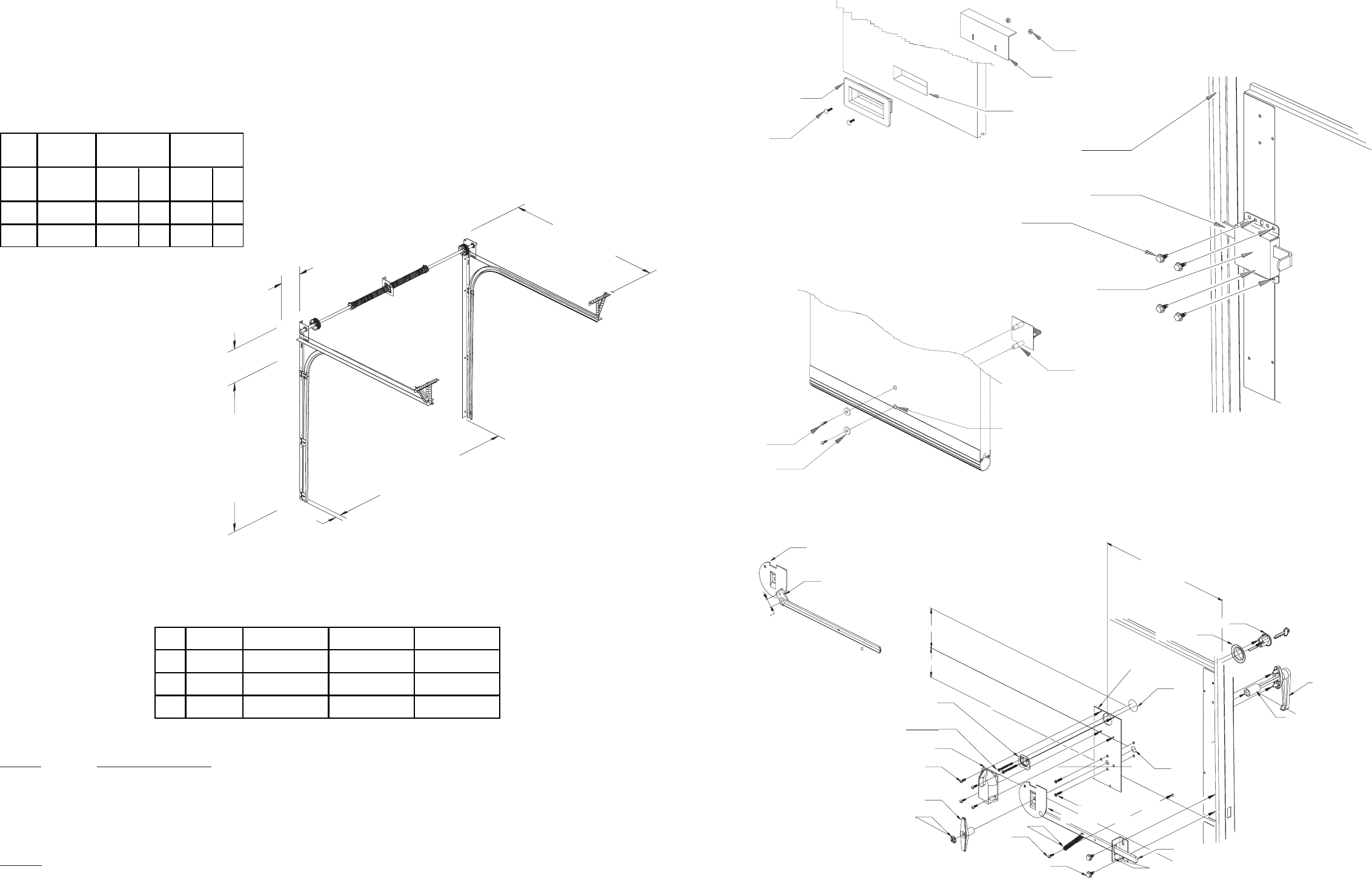

HEADROOM

A

B

SIDE ROOM

DAYLIGHT

OPENING

HEIGHT

BACKROOM

DAYLIGHT

OPENING

WIDTH

SIDE ROOM

OPERATING ZONE

You Can Save Time And Effort If You First Establish All The Facts About

The Operating Zone

HEADROOM CHART For Standard Lift Track (Minimum Distance Required)

Dim. Y INDICATES THE DISTANCE FROM THE HEADER TO THE CENTER LINE OF TORSION SHAFT.

NOTE: 2 1/2 OF ADDITIONAL HEADROOM IS REQUIRED FOR SINGLE TROLLEY OPERATOR INSTALLATIONS.

TRACK DEPTH

SIZE INTO

ROOM

STEEL

and WOOD SOLID TUBE

MASONRY

DOOR HEIGHT

PLUS 18"

DOOR HEIGHT

PLUS 24"

DIM. B

SIDEROOM

TORSION SHAFT

5"

3" 10" 5"

2-1/2" 3-1/2" 10"

3"

DIM. A

SIDEROOM

TRACK

2"

5"

3" TRACK 2" TRACK 2" TRACK

15" RADIUS 15" RADIUS 12" RADIUS

400-8 HEADROOM 15 1/2" 15" 12"

400-12 DIM Y 13" 12 1/2" 9 1/2"

HEADROOM 17 1/2" 17" 14"

DIM Y 14 1/2" 14" 11"

HEADROOM 21" 20 1/2" NA

DIM Y 16 1/2" 16" NA

DRUMS DIMS

5250-18

800-32

PG. 2

1. Daylight Opening; Exact size of finished opening

2. Sideroom; required distance from the door opening to a wall or any obstruction. Refer To Sideroom Chart

3. Headroom; required distance from top of door opening to the ceiling or underside of joists. Refer To Headroom Chart

4. Backroom; required distance from door opening header to the furthest back point to which the door track or operator unit, and their

brackets, will extend.

The Operating Zone is the area surrounding the door opening, extending upward and backward as far as the door will travel. We call it

the Operating Zone because it is the area that the door will have to operate within and the dimensions are critical and must be known in

advance of a door and operator installation.

STEP 1. Verify The OPERATING ZONE Dimensions

A - Exact size of finished daylight opening. Do you have the correct door size?

B - Sideroom requirements for track and spring shaft. (Refer to sideroom chart)

C - Headroom requirements. (Refer to headroom chart)

D - Backroom (depth into room) Manual lift = Door height plus 18 Operators = Door height plus 48

E - Jambs must be plumb and solidly attached to the building. Floor must be level or exact gradeline established

before you start.

STEP 2. Shipping tags show important information, door size, track size and type, spring size and hardware type.

Verify that all material is present and correct before attempting installation.

PG. 15

Vertical Track

5/8 X 20 self-drilling

TEK screws (4)

Align with slot in track

Outside Step Plate

3/16 holes drilled 1-3/16

and 3-3/8 from bottom

of section.

#8 Self-Tapping

Screw (2)

#8 Washer (2)

Rim Cylinder Plate

(2) 1-7/8 X #12 pan head

screws (broken to length

1-7/8 or 1-1/4

Inside T Handle

5/8 X 20 self-drilling

TEK screw (2)

Lock Plate

spring

Night Latch

Lock Bar

Cupped Lock Disk

Tinnerman Nut

(see note)

7/8

1-1/4

(2) #10 Pan head screws

(4) 3/4 X #8 screws

1/2 X #12

screw

Lock Plate

Trim Ring

12-1/2

Rim Cylinder

Lock Disk for 3 track

1/8 X 1-1/8 X 1-1/8

Steel welded to lock

plate

7/8 Extension

Side Lock

PG. 15

Fig. U

Fig. T

Fig. W

1/4 X 5/8

carriage bolt (2)

Step Dish

Cut Out

1/4-20 Nut (2)

Inside Step Plate

4-1/4

4

Outside Handle

1-5/16 PVC Spacer

5150 & 5155

1-11/16 PVC Spacer

5200 & 5255