17

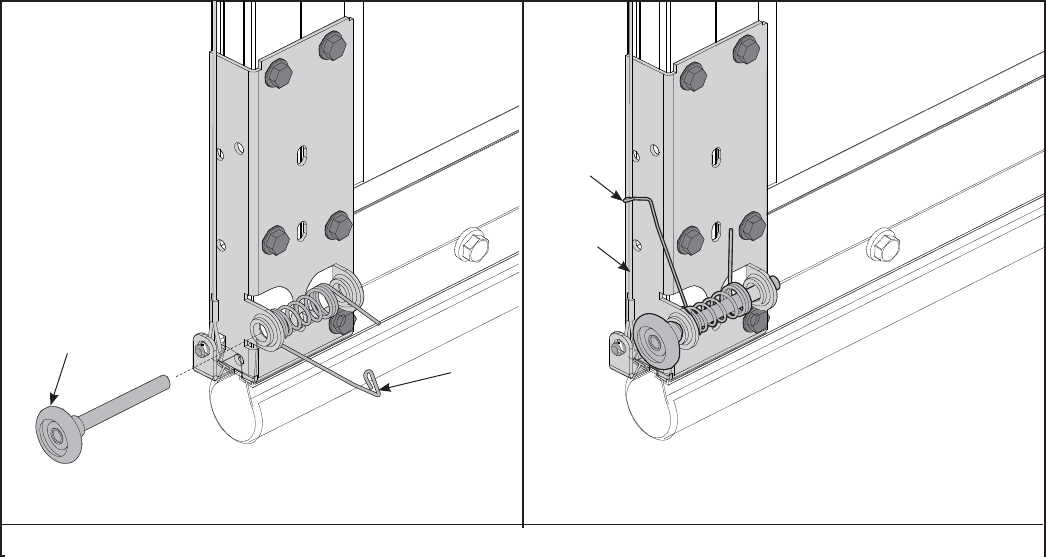

CABLE KEEPER INSTALLATION

Place cable keeper between roller carrier tabs. Insert roller through holes in the tabs and through cable keeper. Rotate arm up and hook around cable, letting cable

keeper arm pull against the counterbalance cable, keeping it taut, as shown in FIG Y.

NOTE: Cable keepers are color coded, black for right hand and red for left hand.

IMPORTANT: Cable keepers are intended to keep cables from coming off drums on manually operated doors.

ROLLER

CABLE

KEEPER

CABLE

KEEPER

CABLE

CHAIN HOIST INSTALLATION (STANDARD LIFT APPLICATIONS)

Chain Hoists and JackShaft Operators are limited to:

1.) Standard Lift Doors with roof pitch track 2:12 or greater.

2.) High Lift track greater than or equal to 24”.

3.) High Lift track 12” thru 24” with roof pitch track 1:12.

If your door is to be trolley operated, it is recommended that an optional strut be installed on the top section.

Wayne-Dalton recommends the use of a trolley rail(s) and auxiliary shaft for standard or high lift doors below these limits. Cable Keepers are recommended for all chain

hoist or jackshafts operators. Install the chain hoist or sprocket as close to the end bearing bracket as possible, to minimize torsion shaft defl ection, as shown in FIG Z.

Chain tensioners are recommended for door over 144 sq. ft. with jackshaft operators.

Wayne-Dalton recommends the use of a trolley rail(s) coupled to an auxiliary shaft that is powered by a side mount type chain hoist as shown in FIG Z.

9’” of extra headroom are required for these installations.

Assemble the trolley rail as per the manufactures installation instructions. Secure the trolley header bracket to the building using the appropriate fasteners

(2-5/16” X 1-5/8” lags for wood, 2-5/16” X 1” self drilling and tapping screws for steel, and 2-3/8” 2-1/2” sleeve anchors for masonry.

Back hang the trolley using angles, center hang supports are required for doors over 14’ wide and 12’ high.

Attach the trolley arm to the bracket.

Secure the auxiliary shaft to the building with bearing brackets and couple the shaft to the trolley rail.

Assemble the chain hoist and secure to the auxiliary shaft.

FIG Y