17. Annual Maintenance Cont.

17.5 Checking the pressurization in the expansion vessel:

Empty the central heating system as described in section 17.3 of this chapter and check

that the pressure in the expansion vessel is not less than 1 bar (14.5 psi). See also

section 13.2 page 26 of this manual. If the pressure should be lower, take steps to correct

the pressure level.

17.6 Cleaning the burner:

The sloping and multi-gas type burner (7 on page 11) does not need special maintenance,

but it is sufficient to dust it with a bristle paintbrush.

17.7 Checking the flue:

Have the integrity of the flue outlet pipe (24 on page 12) air intake pipe (25 on page 12),

checked periodically, the venturi device (23 on page 12) cleaned and the efficiency of the

flue safety circuit checked at least once a year. For all the above maintenance operations

it is advisable to call an approved Service Engineer.

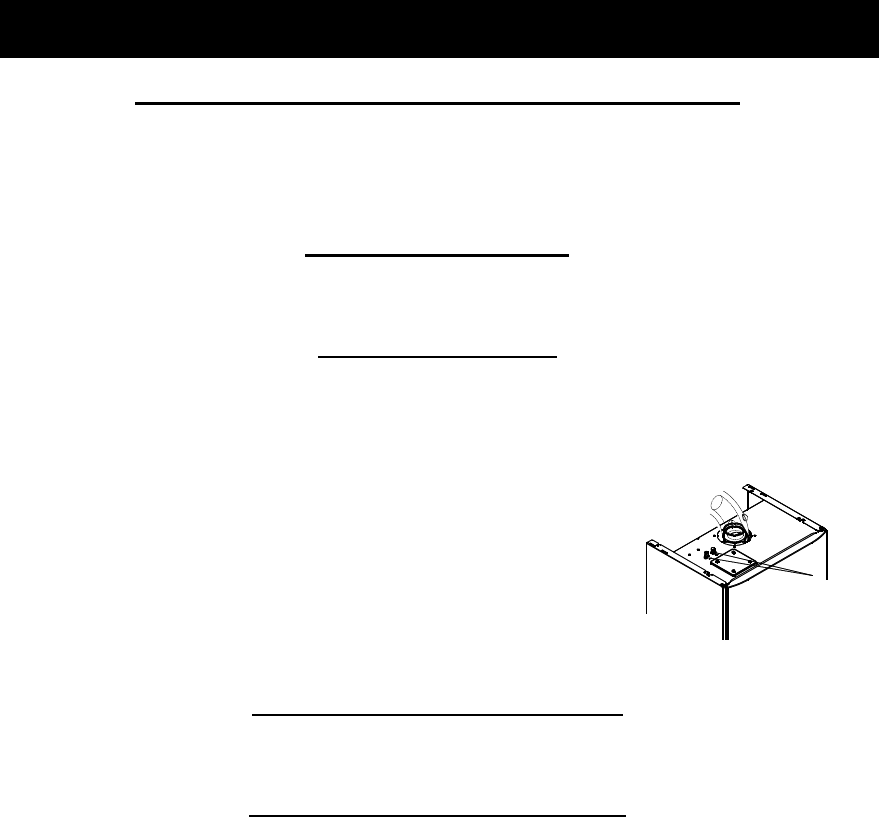

To check the pressure at the venturi device, use the test points (12 on page 11).

• Remove the caps of

the pressure test

points and connect a

differential pressure

gauge.

• Switch on the boiler

• Compare the value on

the gauge with the

minimum values of

venturi pressure

indicated in the

Section 2 on page 10.

Venturi test

points

Figure 17.4

17.8 Visual inspection of appliance:

Visually inspect all water joints, seals and connections for any evidence of leakage and

retighten, grease or replace them as necessary.

17.9 Gas pressures and soundness:

Check appliance for gas soundness. Recheck operational pressures and adjust as

necessary as described in Section 15.4 page 32 of this manual.

RIVA HEAT ONLY MANUAL - REV A

38