10 WSHP-SVN08B-EN

FLOOR

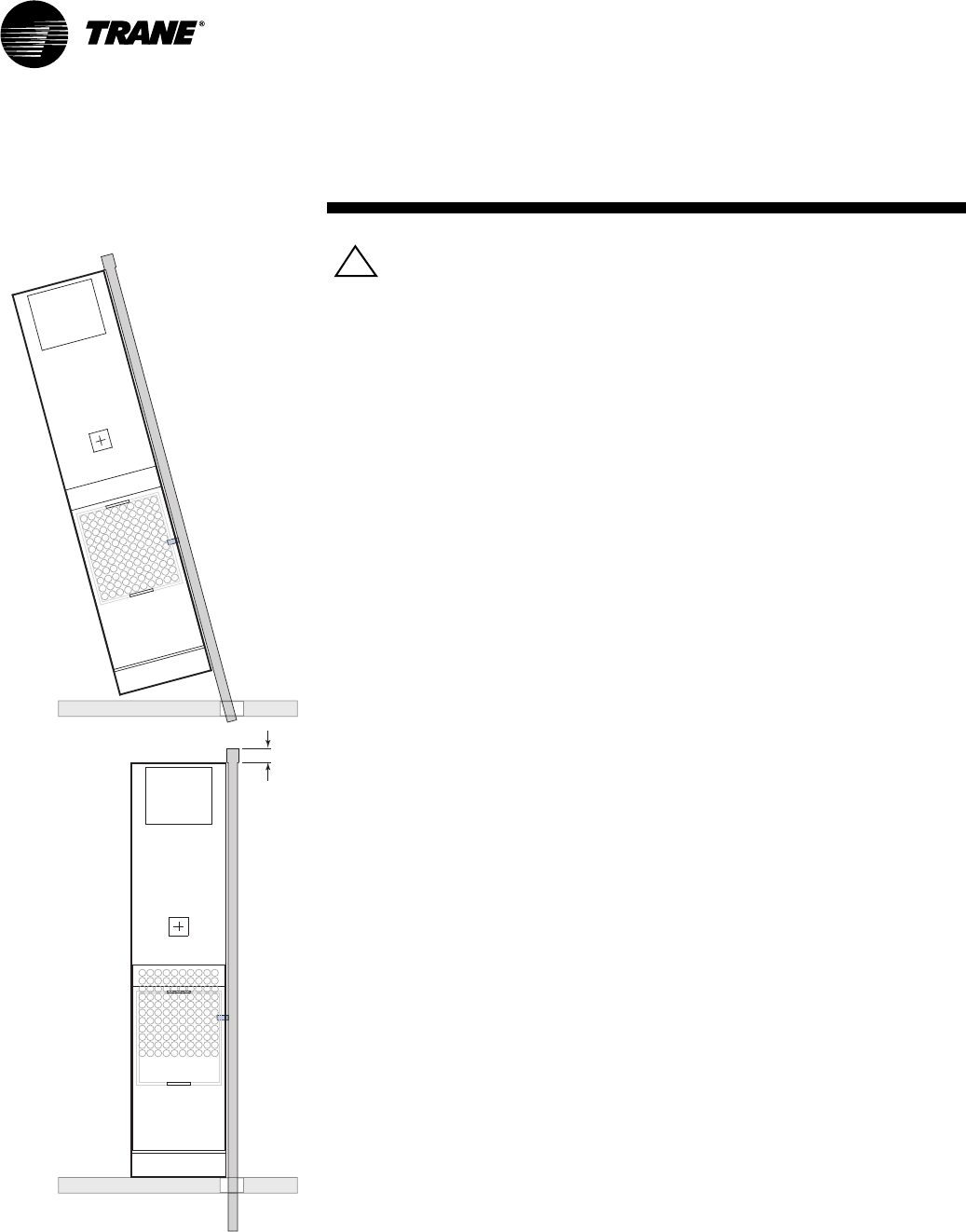

FLOOR

3" SWAGE

WARNING

Improper Unit Lift!

Test lift unit approximately 24

inches to verify proper center of

gravity lift point. To avoid

dropping of unit, reposition lifting

point if unit is not level. Failure to

properly lift unit could result in

death or serious injury or possible

equipment or property-only

damage.

Unit Placement

If unit cabinet assembly includes fac-

tory provided risers, and "no" field

provided between-the-floor riser ex-

tensions, please move to Step 1.

Note: Risers are designed to accom-

modate a maximum of 1 1/2" to 3" ex-

pansion and contraction. If the total

calculated riser expansion exceeds 3",

expansion devices must be field pro-

vided.

If unit cabinet assembly includes fac-

tory provided risers and field provided

between-the-floor riser extensions are

required, install the extensions before

installing the cabinet.

1 Install drain valve, shut-off/balanc-

ing valves, flow indicators and

drain at the base of each supply and

return riser to enable system flush-

ing at start-up, balancing and ser-

vice/maintenance.

2 Lift cabinet into space while align-

ing it into the 3"swage of the riser

below.

Note: Take extra care as not to scrape

or dent risers during positioning. The

riser should fall approximately 2" into

the 3" swage. This will allow for the

variation in floor-to-floor dimensions,

and keep the riser joints from bottom-

ing out.

3 Level the cabinet.

4 Plumb risers in two planes to as-

sure proper unit operation and con-

densate drainage.

5 Anchor all units into place.

6 For field provided risers, center the

supply/return stubouts into the unit

expansion slots. The stubouts

should be perpendicular to the cab-

inet panel.

7 Verify all risers are vertical and that

they penetrate the swaged joint at

least 1". Riser should not be al-

lowed to bottom out.

8 Braze riser joints. Soft solder or

low-temperature alloys should not

be used in this application.

9 If risers are field provided, it is rec-

ommended that the risers be an-

chored to the building structure

with a minimum of one contact

point. For expansion and contrac-

tion reasons, do not fasten risers

rigidly to the building.

10 Seal access holes made through the

cabinet for piping with suitable ma-

terial to help eliminate air leakage.

11 See page 14 for system flushing.

Water Connection

For vibration isolation, it is recom-

mended that flexible steel braided

hoses be installed instead of hard pip-

ing between the vertical risers and the

unit chassis.

Trane offers 4-types of hose kit varia-

tions:

• Stainless steel braided flexible

hose with manual shut-off (ball)

valves

• Stainless steel braided flexible

hose with manual deluxe shut-off

(ball) valves

• Stainless steel braided flexible

hose with manual circuit-setter

valve

• Stainless steel braided flexible

hose with automatic balancing

valve

Additional accessories, such as a

strainer are recommended for use to

eliminate contaminants from entering

the co-axial water-to-refrigerant heat

exchangers.

Installation

Figure 2: Stacking illustration

!