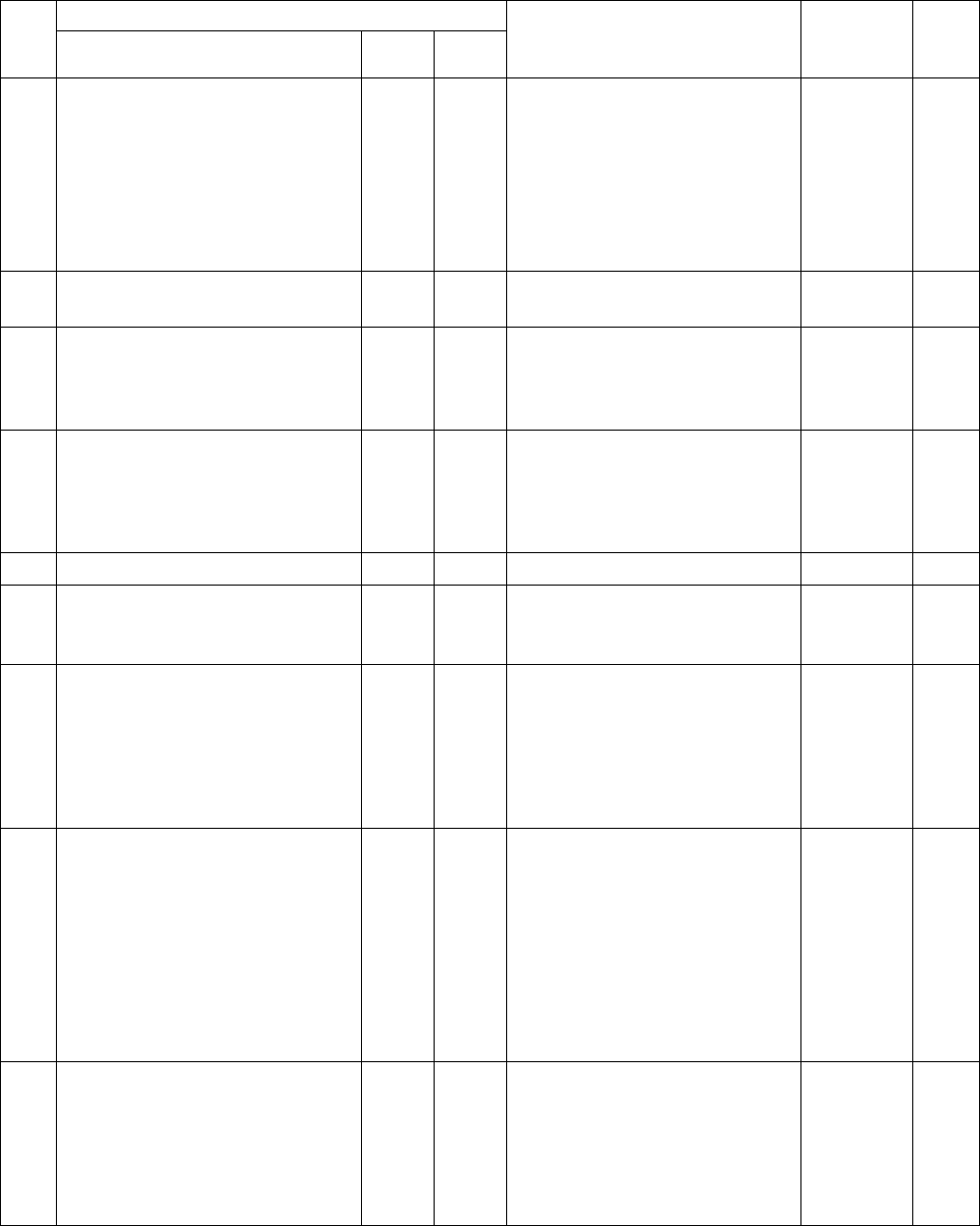

71

Toshiba

H04

Operation of case thermostat

When the case thermostat exceeds

125°C.

O

×

1.Check the refrigeration cycle (gas

leak).

2.Check the case thermostat and

connector.

3.Check that the service valve is fully

open.

4.Defect of the pulse motor valve.

5.Check for a kinked piping.

492

L10

Unset service PC board jumper

Jumpers J800-J803 have not been cut.

O

× 1.Cut J800-J803. 1 92

L29

The communication between the

outdoor PC board MUCs error

No communication signal between IPDU

and CDB.

O

× 1.Replace the outdoor control board. 1 93

P03

The outlet temperature error

When the discharge temperature sensor

(TD) exceeds 111°C.

O

×

1.Check the refrigeration cycle (gas

leak).

2.Defect of the pulse motor valve.

3.Check the resistance value of the

discharge temperature sensor (TD).

494

P04 The high pressure switch error O

× 10 94

P05

The power supply voltage error

When the power supply voltage is

extremely high or low.

O

×

1.Check the power supply voltage.

(AC230 V±23 V)

494

P07

Overheating of heat-sink error

When the heat-sink exceeds 105°C.

O

×

1.Check the thread fastening and

heat-sink grease between the

outdoor control board and the heat-

sink.

2.Check the heat-sink fan duct.

3.Check the resistance value of the

heat-sink temperature sensor (TH).

495

P15

Detection of gas leak

When the discharge temperature sensor

(TD) exceeds 106°C for consecutive 10

min.

When the suction temperature sensor

(TS) exceeds 60°C for cooling or 40°C

for heating for 10 consecutive min.

O

×

1.Check the refrigeration cycle (gas

leak).

2.Check that the service valve is fully

open.

3.Defect of the pulse motor valve.

4.Check for a kinked piping.

5.Check the resistance value of the

discharge temperature sensor (TD)

and the suction temperature sensor

(TS).

495

P19

The 4-way valve inversion error

When the heat exchange temperature

sensor (TE) exceeds 30°C or the suction

temperature sensor (TS) exceeds 50°C

during the heat pump operation.

O

×

1.Check the operation of the 4-way

valve unit or the coil characteristics.

2.Defect of the pulse motor valve.

3.Check the resistance value of the

heat exchange temperature sensor

(TE) and the suction temperature

sensor (TS).

496

Check

code

Diagnostic functional operation

Determination and action

Number of

abnormalities

for

confirmation

Detailed

item

Operational cause

Backup

present

Automat

ic reset

+00A09-002_01EN_SVM_ALL_Air_to_Water.book Page 71 Monday, October 5, 2009 2:09 PM