- 25 -

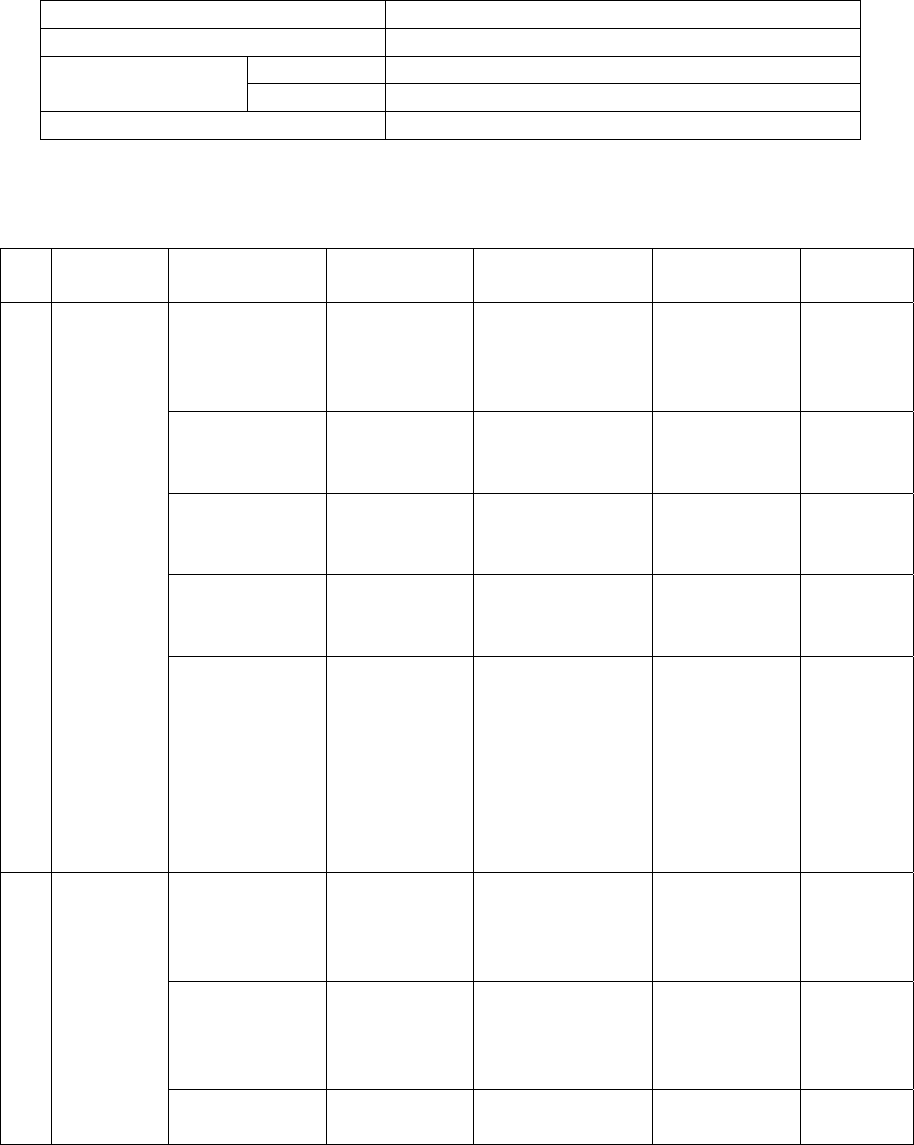

Table 7 Inspection Frequency

Type of inspection Inspection frequency

Patrol Inspection Once every 6 months

Periodic Inspection Normal Once every 1 to 3 years or every 3,000 operations

Detailed Once every 6 years

Unscheduled Inspection As needed

6.4 Periodic Inspection Checkpoints

Table 8 Periodic Inspection Checkpoints

No. Location Item Inspection

method

Criteria Disposition Remarks

1 Operating

mechanism

Loose bolts,

nuts or screws

Tighten using

screwdriver or

wrench.

Make sure all

bolts, nuts and

screws are tight.

Tighten if

loose.

See Table

6 for

tightening

torque.

Dust or foreign

matter inside

Visual

inspection.

Make sure there is

no dust or foreign

matter.

Wipe with a dry

cloth.

Indicator

operation

Visual

inspection.

Make sure

switching status is

properly displayed.

Check the

cause and

repair.

Part warping Visual

inspection.

Make sure no

parts are warped

or missing.

Check the

cause and

repair.

Smooth action Manual

operation.

Visual

inspection

or touch.

See

Lubrication

Manual

Make sure action

is smooth and

shafts turn

smoothly.

If action is not

smooth, apply

a small amount

of lubricant.

2 Main circuit Discoloration

due to heat from

conducting parts

Visual

inspection.

Make sure there is

no discoloration.

Check the

cause and

repair.

Loose bolts,

nuts or screws

Tighten using

a wrench.

Make sure all

bolts, nuts and

screws are tight.

Tighten if

loose.

See Table

6 for

tightening

torque.

Dust on surface

of interrupter

Visual

inspection.

Make sure there is

no surface dust.

Wipe with a

clean dry cloth.