28

NOTE: DIAGRAMS & ILLUSTRATIONS NOT TO SCALE.

The manufacturer reserves the right to make changes at any time, without notice, in design, materials, specifications, prices and also to discontinue colors, styles and products.

Consult your local distributor for fireplace code information.

LHP

1110 West Taft Avenue • Orange, CA 92865

Printed in U.S.A. © 2002 by Lennox Hearth Products

P/N 700,001M REV. H 09/2005

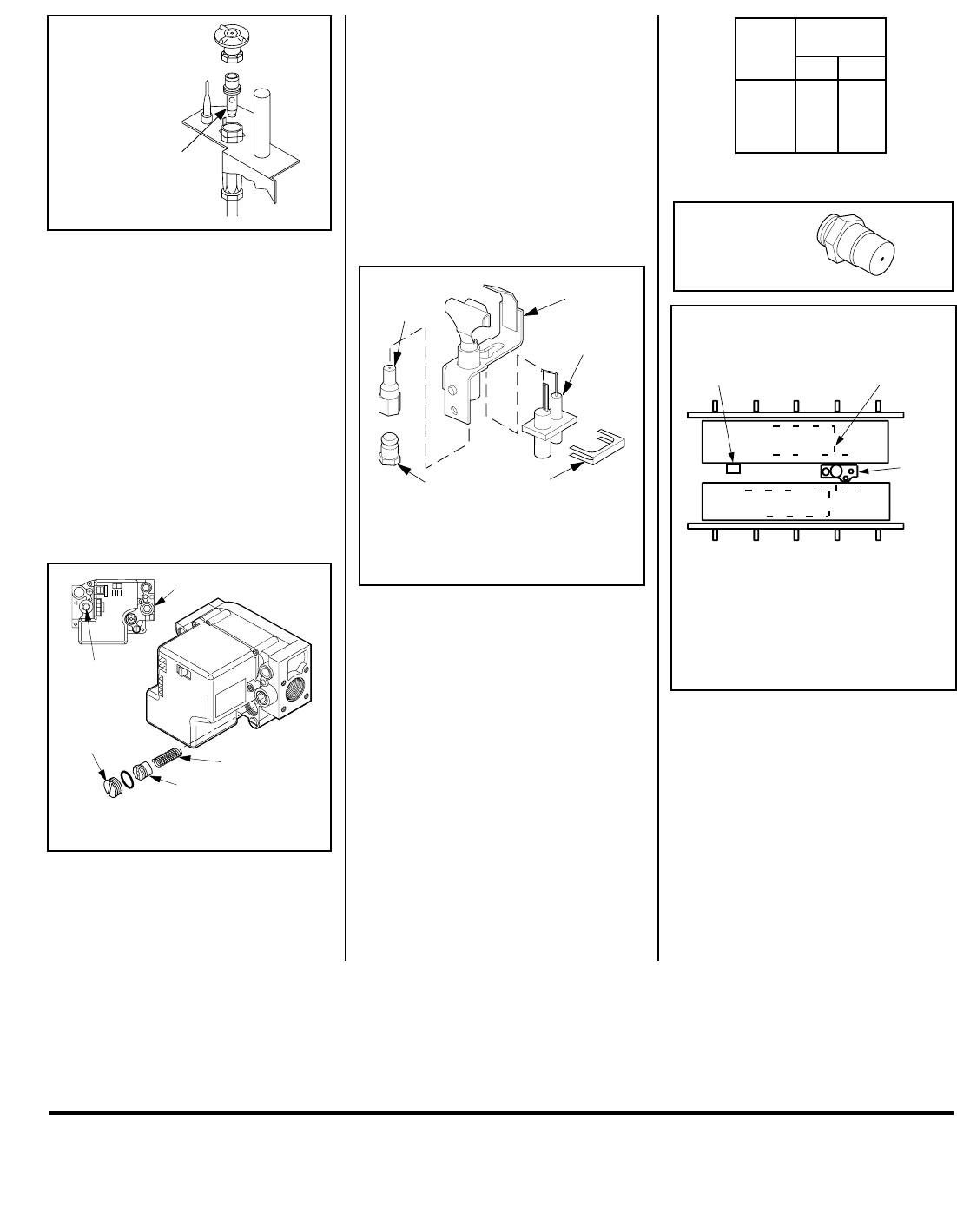

Pilot

Orifice

Retaining

Clip

Ignitor

Assembly

Pilot

Assembly

Pilot

Orifice

Flare Nut

Note: If the ignitor is damaged, a replacement

kit is available, order Catalog No. 87L54.

BURNER POSITIONING

REAR BURNER

FRONT BURNER

PILOT

BURNER

Note: The burners are not identical. Position them so

that the circular burner ports run as shown. Note

especially the vertical run of ports relative to the pilot

burner. Bracket A on the rear burner will interfere with

the pilot burner if an attempt is made to install the

rear burner in the front burner’s position.

BRACKET A

BURNER

PORTS

NOTE: INSTALL REAR BURNER FIRST,

THEN FRONT BURNER.

Spring

Adjusting

Screw

Slotted

Cap

PSI

OFF

I

ON

CONTROL

IG

N

ITE

Manifold

Pressure

Test Port

Inlet Pressure Test Port

ledoM

.oN

*ezisecifirO

.taN.porP

TSDC

FPDC

RCDC

LCDC

44#55#

Figure 67

Figure 66

Figure 68

Figure 65

Figure 69

Remove the screw securing the pilot assembly

to its mounting bracket. Back off the flare nut

at the end of the pilot gas line to free the pilot

assembly from the gas line. Remove the pilot

orifice and replace it with the one provided with

the conversion kit. Reinstall the pilot assembly

by reversing the steps detailed here.

When reinstalling the ignitor assembly, use

extreme care to prevent damage and break-

age. Do not apply any leverage to the ignitor

assembly while restoring the retainer clip to

its original position.

* Each model has two burners. Each burner contains

one of these orifices.

NOTE: DIAGRAMS & ILLUSTRATIONS NOT TO SCALE.

Electronic Appliances

Step 7. Honeywell Electronic Valves - See

Figure 66

and the instructions provided with

the kit. Remove the slotted cap screw, o-ring,

pressure-regulating adjusting screw and

spring. Retain all parts for possible later use.

Install new components from the kit. Black

cap and red spring for propane gas units.

Silver cap and stainless steel spring for natural

gas units. Before installing the cap, attach

manometer to the manifold side pressure test

fitting and adjust screw until pressure reads

3.5 inches water column (0.87 kPa) for natural

gas, and 10.0 inches water column (2.49 kPa)

for propane gas.

Step 9. Reassemble the remaining compo-

nents by reversing the procedures outlined in

the preceding steps. Use pipe joint compound

or Teflon tape on all pipe fittings before install-

ing (ensure propane resistant compounds are

used in propane applications, do not use pipe

joint compounds on flare fittings).

Step 10. Attach the conversion label provided

in the conversion kit to the rating plate on the

appliance.

Step 11. Turn on gas supply and test for gas

leaks.

See

Figure 67

and replace the pilot orifice as

follows: Remove the ignitor assembly retainer

clip, and carefully remove the ignitor assembly.

Exercise extreme care to prevent damage to

or breakage of the ignitor assembly.

All Models

Step 8. (Refer to

Figure 63 on page 27

)

A. Remove the two orifices from the manifold

and replace them with the ones provided in the

kit. The following table shows the orifice sizes

for natural and propane models

. Figure 68

illustrates the orifice.

B. Install rear burner first, followed by front

burner, as shown in

Figure 69

. Ensure that the

arm of the venturi of each burner is hooked

onto the air shutter adjustment lever (refer to

Figure 63 on page 27).

The primary air open-

ing can be adjusted by rotating the adjustment

lever from beneath the firebox floor. Refer to

Figure 58 on page 23

for the recommended

minimum primary air opening setting.