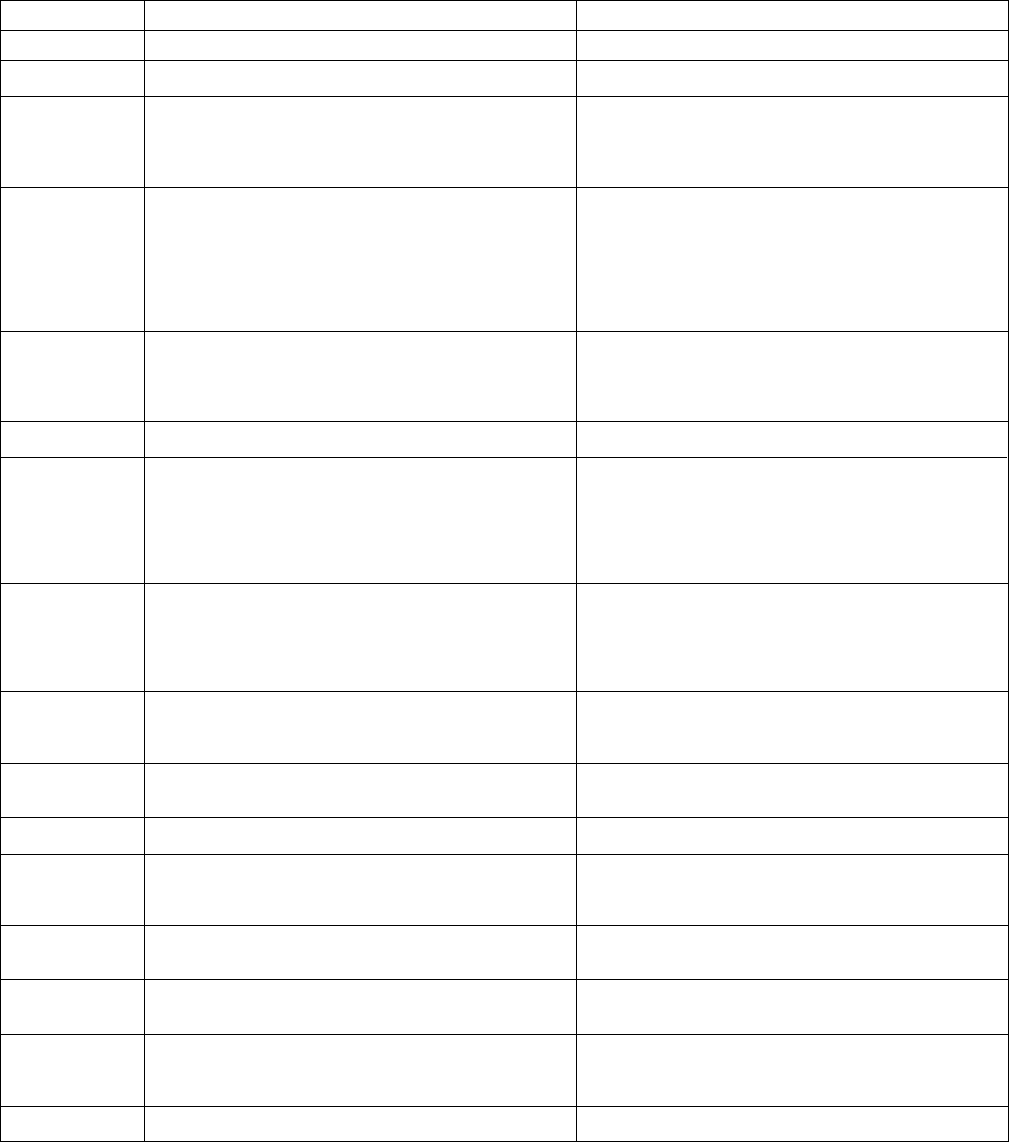

38

Table 10B - Troubleshooting with LED Indicator Assistance for Honeywell Control Board

Not Applicable

Not Applicable

1. Check pressure switch to see if open to start, if not

replace switch.

2. Air fl ow switch jumpered. Remove jumper and check

operation.

1. Look for obstruction or restrictions in appliance air

intake or fl ue outlet that are preventing proper

combustion airfl ow.

2. Moisture or debris in tube that connects pressure

switch and draft inducer.

3. Check spud on power venter housing. Make sure it is

clear.

1. Open manual reset rollout switch.

2. Gas pressure is too high, over fi red condition.

3. Incorrect airfl ow due to blockage or fan motor not

operating.

1. Flame probe miswired or shorted.

1. Gas supply off or gas pressure too low.

2. Flame sense rod contaminated or loose wire.

3. Gas valve switch is off or wires are not connected.

4. Broken or cracked porcelain on spark ignitor

allowing spark to jump to ground and not between

end of probes.

1. Open manual reset rollout switch.

2. Gas pressure too high, over fi red condition causing

high limit to open.

3. Incorrect airfl ow due to blockage or fan motor not

operating.

1. Check pressure from drafter and see if it reads above

set point on pressure switch. Replace bad pressure

switch.

1. Check sensor wire and make sure it is connected

properly.

1. Check for short. If no short replace fuse and start unit.

2. If no short is found, check gas valve for possible over

amp. condition. Replace gas valve.

1. Check transformer for proper voltage. Replace

transformer if not correct.

1. Switch off power and check fl ame rod wiring.

1. Turn unit off and back on. If fault code fl ashes again

check gas valve for problem. If problem found replace

gas valve.

1. Reset board. If code fl ashes again replace board.

Control powered (without call for Heat)

Call for Heat: normal operations

Pressure Switch failed closed

Pressure Switch failed open

Limit circuit open

Flame sensed out of sequence - fl ame still present

Softlockout: Failed to light in four ignition trials

Softlockout: Limit circuit opened during run

(recycle counter at its maximum)

Softlockout: Pressure Switch opened during run; did not

reclose within 2 seconds (fl ame lost and recycle at its

maximum)

Softlockout: Flame failed during run

(recycle at its maximum)

Flame sensed while out of sequence and is now gone

Lockout: Bad fuse detected.

Lockout: Low voltage on 24VAC input

Lockout: Flame Rod shorted to ground or there is a big

leakage from fl ame rod to ground

Lockout: Gas Valve fault

Lockout: Internal Hardware error detected

PATTERN

STATUS CHECK/REPAIR

Short Flash

Heartbeat

2

3

4

5

6+1

6+2

6+3

6+4

6+5

7+1

7+2

7+4

7+5

7+6