18

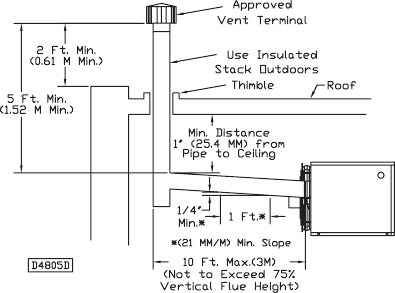

4. Slope horizontal runs upward

from the gas unit heater at least

1/4-inch per foot (21mm/m)

minimum. Horizontal Vent

Connector length should not

exceed 75% of the vertical

height of the vent pipe for single

wall, or 100% of the vertical

height for B-Vent connectors.

Maximum vent connector length

is 10 feet (3m). For exceptions

see Ch. 10 of the National Fuel

Gas Code, ANSI Z223.1.

Horizontal portions of the venting

system shall be supported

at minimum intervals

of

4 feet (1.2m) (in

Canada,

support at

3 foot intervals

(1m)

minimum intervals.

5. Use as few elbows as

possible.

6. Seal all vent pipe joints

and seams to prevent

leakage. Use General

Electric RTV-108, Dow-

Corning RTV-732, or

equivalent silicone

sealant with a temper-

ature rating of 500 deg. F,

HORIZONTALLY VENTED, CATEGORY I - Figure 13

Observe the following precautions

when venting the unit:

1. Use fl ue pipe of the size shown

on Table 5. All heaters must be

vented with a UL Listed, Type B

or single wall vent. Refer to Table

5 for dimensional restrictions.

2. Each unit must have an

individual vent pipe and vent

terminal. Unit must not be

connected to other vent systems

or to a chimney.

3. A minimum vertical rise is

required for Category I venting.

See Table 5 for specifications.

The vent terminal must be at

least 3 feet (1m) above grade,

or in snow areas, at least 3

feet (1m) above the snow line

to prevent blockage by snow.

Install a weather cap over the

vent opening. An Amerivent

Americap or Metalbestos

vent cap must be supplied by

the customer for each power

vented unit.

4. Through the wall venting for these

appliances shall not terminate

over public walkways, or over an

area where the condensate or

vapor could create a nuisance,

hazard, or could be detrimental to

the operation of regulators, relief

valves, or other equipment.

5. Seal all vent pipe joints and

seams to prevent leakage. Use

General Electric RTV-108, Dow-

Corning RTV-732, or equivalent

silicone sealant with a tempera-

ture rating of 500 deg. F, or 3M

# 425 aluminum foil tape (or

equivalent). The vent system

must be installed to prevent

collection of condensate. Pitch

horizontal pipes downward 1/4

inch per foot (21mm per meter)

toward the outlet for condensate

drainage. Install a tee with a

condensate drain at the low point

of the pipe (see Figure 13). As

an alternate, a 3/8 inch diameter

hole may be drilled at the low

point of the pipe for condensate

drainage.

6. Horizontal portions of the venting

system shall be supported at

minimum intervals of 4 feet (1.2m)

to prevent sagging (in Canada,

support at 3 foot (1m) minimum

intervals).

8. Avoid running vent pipe through

unheated spaces. When this

cannot be avoided, insulate the

pipe to prevent condensation of

moisture on the walls of the pipe.

VERTICALLY VENTED, CATEGORY I - Figure 12

Observe the following precautions

when venting the unit:

1. Use flue pipe of the same size

as the fl ue connection(s) on the

gas unit heater 4" (102mm). All

heaters must be vented with a

UL Listed, Type B or single wall

vent, a factory built chimney, or

a lined brick and mortar chimney

that has been constructed in

accordance with the National

Building Code. All tables and

dimensions assume B vent for

the fl ue and single wall pipe or B

vent for the connector.

2. Each unit must have an

individual vent pipe and vent

terminal. Unit must not be

connected to other vent systems

or to a chimney.

3. A minimum vertical rise of 5 feet

(1.5m) is required for Category

I venting. The top of the vent

pipe should extend at least 2

feet (0.61m) above the highest

point on the roof. Consideration

should be made for anticipated

snow depth. Install an Amerivent

Americap or Metalbestos vent

cap over the vent opening.

or 3M #425 aluminum foil tape (or

equivalent).

7. Avoid running vent pipe through

unheated spaces. When this

cannot be avoided, insulate the

pipe to prevent condensation of

moisture on the walls of the pipe.

Insulate vent pipe runs longer

than 10 ft (3m). Insulation should

be a minimum of 1/2" (12.7 mm)

thick foil faced.

Figure 12

STANDARD COMBUSTION