43

A.0500.551 – IM-TGMAG/02.00 EN (02/2008)

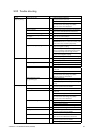

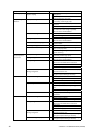

Symptom Cause Remedy

Pump leak O-rings, sealing rings or gasket damaged

or not correctly assembled

41 • Check condition of O-rings and assemble them

correctly or replace them

• Check condition and clean/repair sealing faces

• Replace gasket under top cover or safety relief

valve and/or sealing rings under plugs

Note! If symptoms persist, the pump must be taken out of service immediately. Contact your distributor.

3.20.1 Instructions for re-using and disposal

3.20.1.1 Re-use

Re-use or putting the pump out of service should only be undertaken after complete draining and

cleaning of the internal parts.

Note! When doing so, observe adequate safety regulations and take environmental

protection measures.

Liquids should be drained and following local safety regualtions the correct personal equipment

should be used.

3.20.1.2 Disposal

Disposal of the pump should only be done after it has been completely drained. Proceed according

to local regulations.

Where applicable please disassemble the product and recycle the parts’ material.

3.21 Maintenance instructions

3.21.1 General

This chapter only describes operations that can be performed on-site for normal maintenance.

For maintenance and repair requiring a workshop contact your distributor.

• Insufcient,wrongand/orirregularmaintenancecanleadtomalfunctionsinthepump,high

repair costs and long-term inoperability. Therefore, you should carefully follow the guidelines

given in this chapter.

During maintenance operations on the pump due to inspections, preventive maintenance or

removal from the installation, always follow the prescribed procedures.

Non-compliance with these instructions or warnings may be dangerous for the user and/or

seriously damage the pump/pump unit.

• Maintenanceoperationsshouldbeperformedbyqualiedpersonnelonly.Alwayswearthe

required safety clothing, providing protection against high temperatures and harmful and/or

corrosive fluids. Make sure that the personnel read the entire instruction manual and, in

particular, indicate those sections concerning the work at hand.

• SPXProcessEquipmentisnotresponsibleforaccidentsanddamagecausedbynon-

compliance with the guidelines.

• Personnelwhocarryacardiacpacemakershouldnotbeallowedtoworkonapumpequipped

with magnetic coupling!. The magnetic field is sufficiently strong to affect the proper operation

of a pacemaker, so keep a safe distance of at least 3 m.

• Donotcomeclose(notlessthan1m)tothemagneticcouplingwithsubjectsequippidwith

magnetic data carrier such as cheque cards, computer disks, watches etc. to avoid damage

and/or loss of information.

3.21.2 Preparation

3.21.2.1 Surroundings (on site)

Because certain parts have very small tolerances and/or are vulnerable, a clean work environment

must be created during on site maintenance. Particularly remove metallic chips or any dirt which

could be attracted by the components of the magnetic coupling.