41

A.0500.551 – IM-TGMAG/02.00 EN (02/2008)

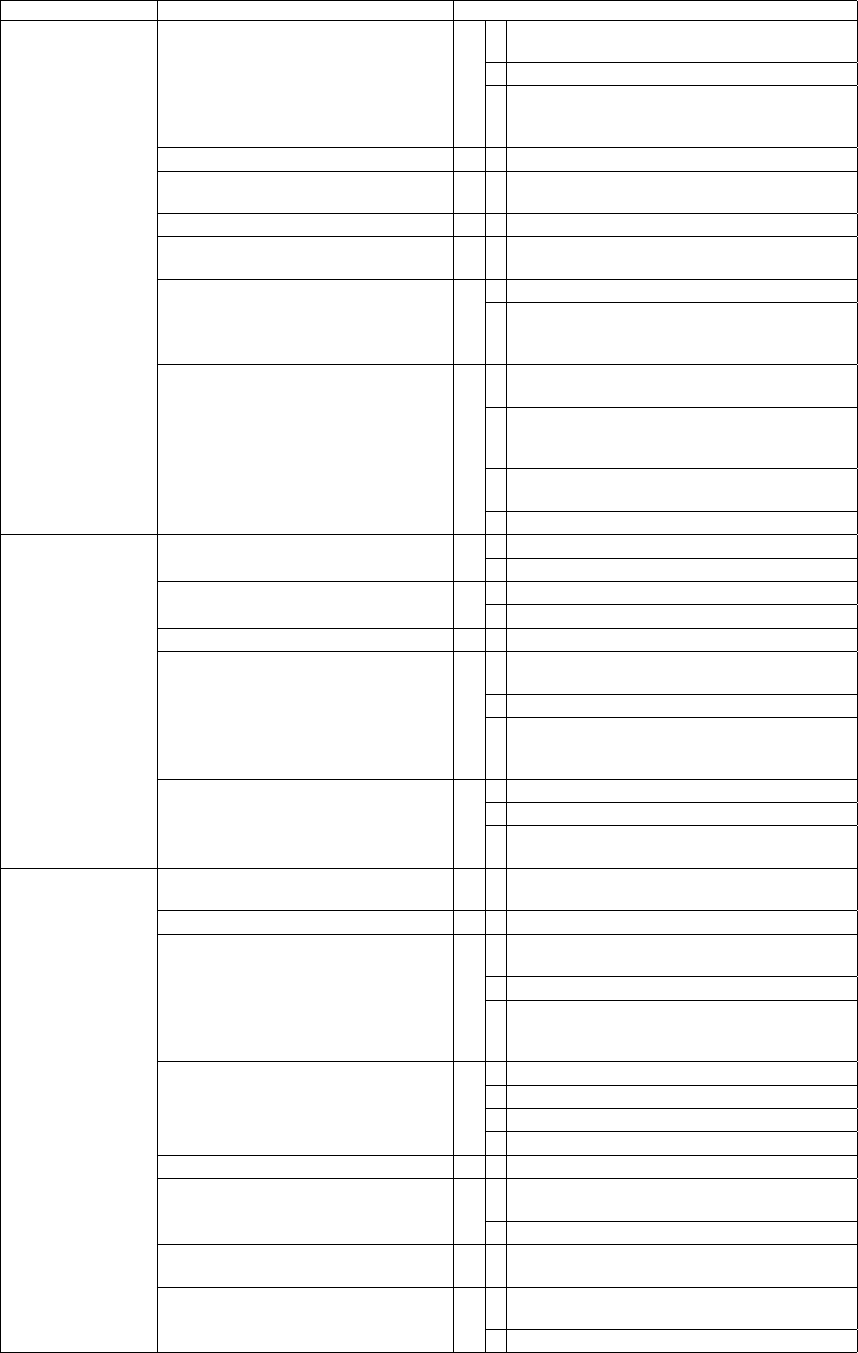

Symptom Cause Remedy

No flow

Pump not priming

Suction lift too high 1 • Reduce difference between

pump and suction tank level.

• Increase suction pipe diameter.

• Reduce length and simplify suction pipe (use as

few elbows and other fittings as possible).

Also see section 3.18 Installation.

Air leak in suction line 2 • Repair leak.

Very low viscosity 3 • Increase pump speed and reduce axial clearance

(see section 3.21 Maintenance instructions).

Suction strainer or filter clogged 4 • Clear suction strainer or filter.

Pump casing incorrectly installed

after repair

5 • Install pump casing correctly.

See section 3.18 Installation.

Wrong direction of rotation of motor 6 • For 3-phase drivers change 2 connections.

• Change suction and discharge opening.

(Attention! Check the location of the safety relief

valve and correct circulation pump insert).

Magnetic coupling is slipping 7 • Check/correct assembly of rotor shaft and bear-

ings and magnetic coupling

• Check start-up conditions for the magnetic cou-

pling in combination with applied electrical motor

if necessary add fly-wheel or apply soft start.

• Check operating parameters against break-away

torque of the magnetic coupling.

• Check if the pump is blocked, remove blockage.

Irregular flow Liquid level in suction tank falls too low 8 • Correct liquid supply

• Provide a liquid level switch

Output too high 9 • Reduce pump speed/or install a smaller pump.

• Install by-pass line with check-valve.

Air sucking 10 • Repair leak in suction line.

Cavitation 11 • Reduce difference between pump and suction

tank level.

• Increase suction pipe diameter.

• Reduce length and simplify suction pipe (use as

few elbows and other fittings as possible).

Also see chapter 3.18 Installation.

Liquid vaporises in pump

(e.g. by heating up)

12 • Check temperature.

• Check vapour pressure of liquid.

• Reduce pump speed. If necessary install a larger

pump.

Not enough capacity Pump speed too low 13 • Increase pump speed. Attention! Do not exceed

maximum speed and check NPSHr.

Air sucking 14 • Repair leak in suction line.

Cavitation 15 • Reduce difference between pump and suction

tank level.

• Increase suction pipe diameter.

• Reduce length and simplify suction pipe (use as

few elbows and other fittings as possible).

Also see section 3.18 Installation.

Back pressure too high 16 • Check discharge pipe.

• Increase pipe diameter.

• Reduce working pressure.

• Check accessories (filter, heat exchanger, etc.).

Safety relief valve set too low 17 • Correct pressure setting.

Viscosity too low 18 • Increase pump speed. Attention! Do not exceed

maximum speed and check NPSHr.

• If necessary, install a larger pump.

Axial clearance 19 • Check axial clearance and correct.

See section 3.21 Maintenance instructions.

Gases come free 20 • Increase pump speed. Attention! Do not exceed

maximum speed and check NPSHr.

• Install a larger pump

3.20 Trouble shooting