42

A.0500.551 – IM-TGMAG/02.00 EN (02/2008)

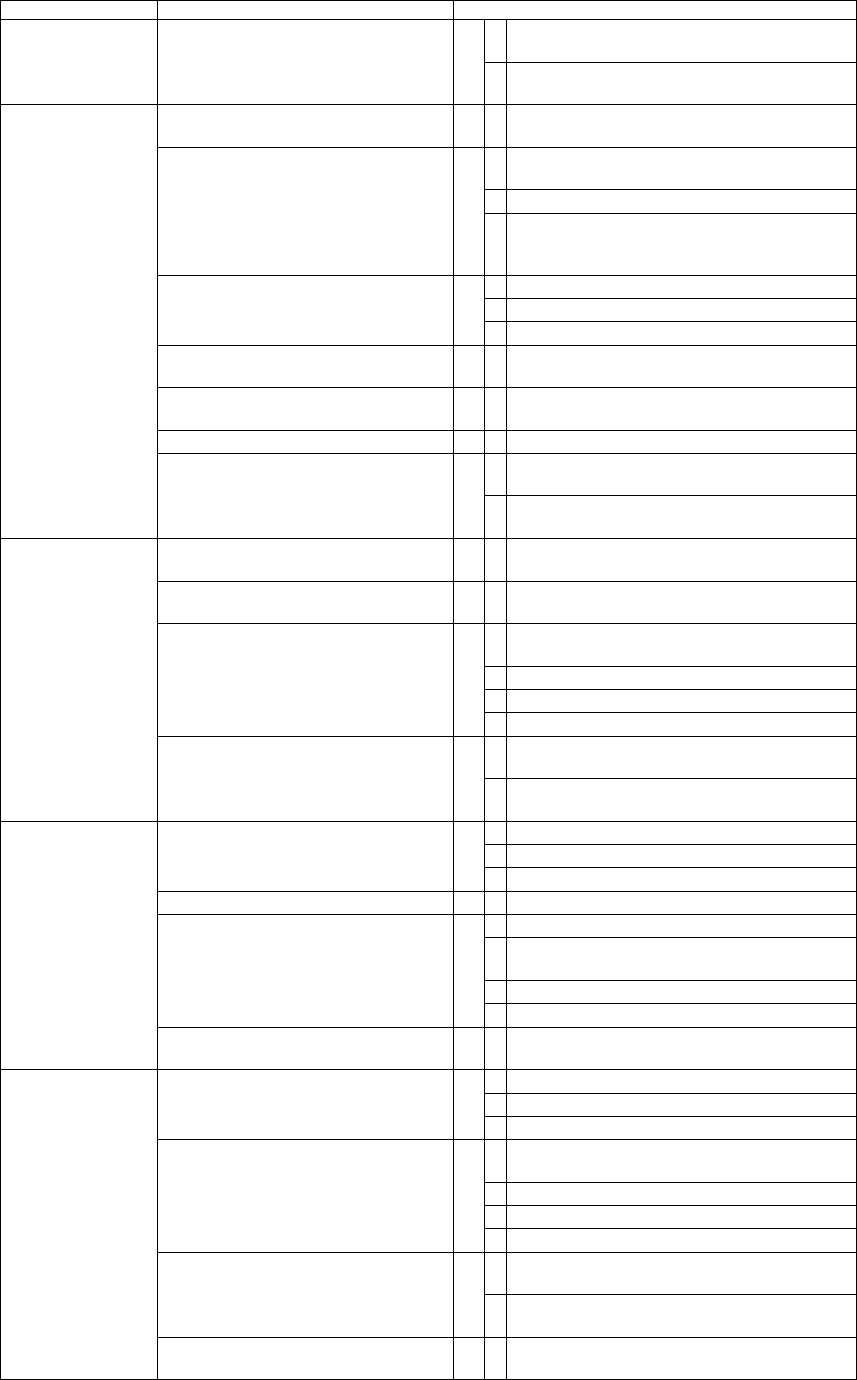

Symptom Cause Remedy

Not enough capacity Liquid leaking back to suction over the

magnetic coupling

21 • Check/correct assembly of the circulation pump

arrangement

• Check/adjust axial clearance of the circulation

pump and rear face of the rotor

Pump too noisy

Vibrations

Pump speed too high 22 • Reduce pump speed.

If necessary, install a larger pump.

Cavitation 23 • Reduce difference between pump and suction

tank level.

• Increase suction pipe diameter.

• Reduce length and simplify suction pipe (use as

few elbows and other fittings as possible).

Also see section 3.18 Installation.

Backpressure too high 24 • Increase pipe diameter.

• Reduce working pressure.

• Check accessories (filter, heat exchanger, etc.).

Coupling misalignment 25 • Check and correct alignment.

Also see section 3.18 Installation.

Vibration of base plate or pipings 26 • Make base plate heavier and/or affix baseplate/

pipework better.

Ball bearings damaged or worn 27 • Replace ball bearings.

Un-balance of the outer magnetic rotor 28 • Check/correct assembly of the outer magnetic

rotor on the pump shaft

• Check correct tightening of bolts, secure bolts

against loosening.

Pump consumes

too much power or

becomes hot

Pump speed too high 29 • Reduce pump speed.

If necesary, install a larger pump.

Coupling misalignment 30 • Check and correct alignment.

Also see section 3.18 Installation.

Viscosity too high 31 • Increase axial clearance.

See section 3.21 Maintenance instructions.

• Heat pump.

• Reduce pump speed.

• Increase discharge pipe diameter.

Excessive friction losses inside rotor shaft

/ bearing arrangement

32 • Check/correct axial clearance of circulation pump

and rear face of the rotor

• Check axial clearance of the plain bearing ar-

rangement replace bearing if necessary

Rapid wear Back pressure too high 33 • Increase pipe diameter.

• Reduce working pressure.

• Check accessories (filter, heat exchanger, etc.)

Solid matter in liquid 34 • Filter liquid.

Pump runs dry 35 • Correct liquid supply.

• Provide liquid level switch or dry running protec-

tion.

• Heat up liquid.

• Stop or reduce air sucking.

Corrosion 36 • Change pump materials or application

parameters.

Motor overloading Back pressure too high 37 • Increase pipe diameter.

• Reduce working pressure.

• Check accessories (filter, heat exchanger, etc.).

Viscosity too high 38 • Increase axial clearance.

See section 3.21 Maintenance instructions.

• Heat pump.

• Reduce pump speed.

• Increase discharge pipe diameter.

Excessive friction losses inside rotor shaft

/ bearing arrangement

39 • Check/correct axial clearance of circulation pump

and rear face of the rotor

• Check axial axial clearance of the plain bearing

arrangement replace bearing if necessary

Rotor shaft runs against pump cover 40 • Check axial axial clearance of the plain bearing

arrangement replace bearing if necessary