30

Maintenance

Distribution System Maintenance

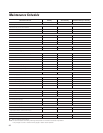

To keep your MD cooling tower operating at peak performance, it may be

necessary to clear the spray system of debris or sediment. To access the

spray system, remove the drift eliminators as explained in the previous

section. Observe the spray system with full ow on the unit. Each nozzle

should produce a cone pattern spray which overlaps the adjacent nozzle

patterns—see image.

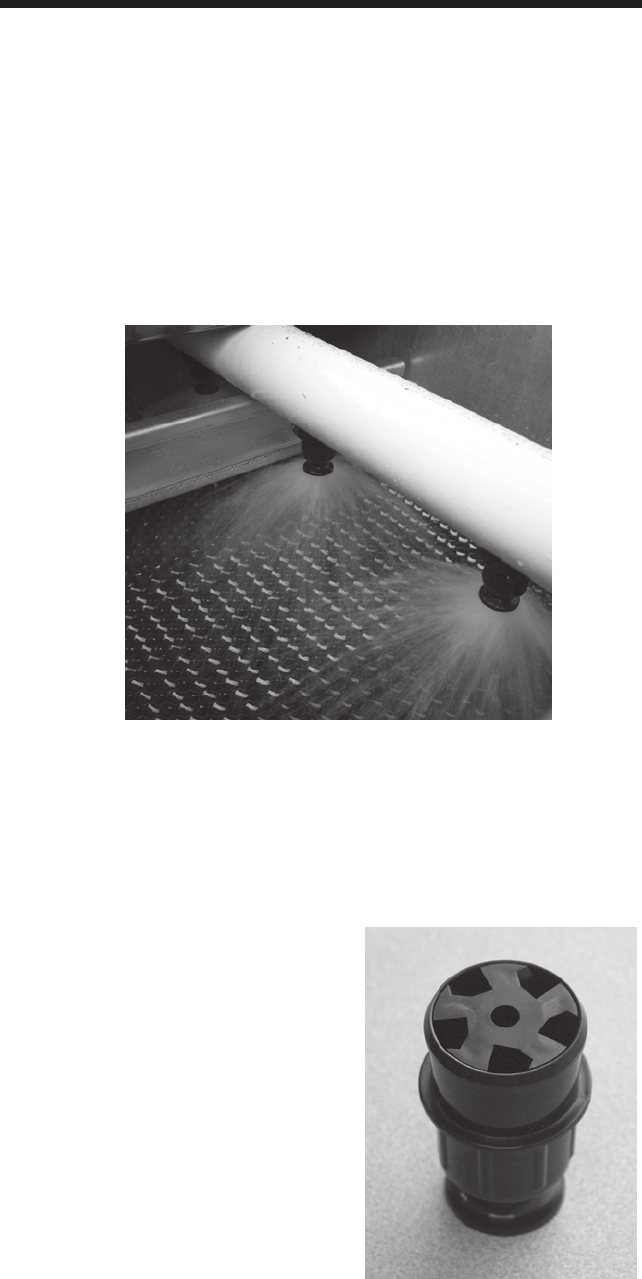

If a nozzle appears clogged or is not producing a cone patter, remove the

nozzle and clean all surfaces. To remove the nozzle, pull down sharply on

the plastic component, leaving the rubber grommet seated in the PVC pipe.

Inspect the nozzle for cleanliness or broken pieces. Each nozzle should

have a turbulator inside the outer shell—see image. If the nozzle appears

broken or damaged, consult your Marley representative for replacement

parts. Insert the nozzles by pressing it

back into place inside the rubber grom-

met. It may be necessary to wet the nozzle

and grommet to facilitate assembly.

It may also be necessary to remove an

entire branch arm from the spray system.

Each arm is held in place with a retention

strap bolted to the branch arm supports.

Remove the bolts attaching the strap to

the support and pull sharply on the branch

arm to disengage from the header box.

It may be necessary to rotate the branch