23

Maintenance

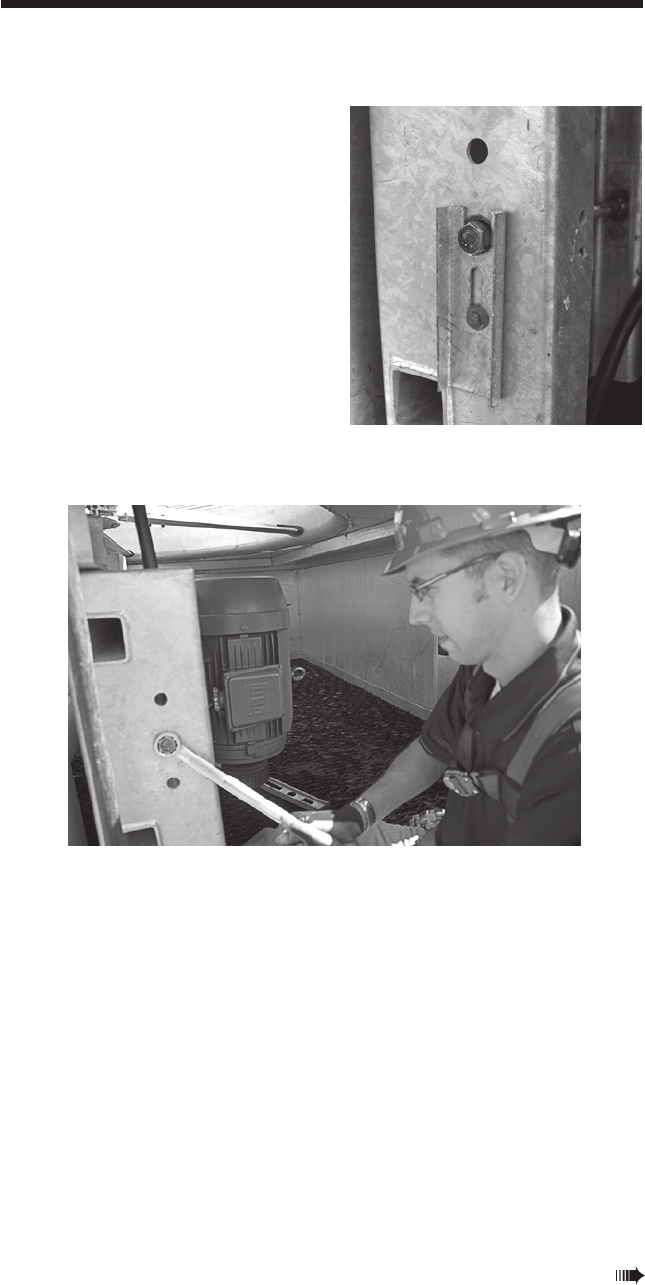

the plenum the rod retention is held in

place with fasteners. Loosen fastener

and slide the bracket away from the

adjusting rod. Turn the rod clockwise

to drive the motor away from the fan

(tighten belts) or counterclockwise to

drive the motor toward the fan (loosen

the belts). There is no need to loosen

any other hardware to adjust the belt

tension. After belt tension is adjusted

to a satisfactory position, install the rod

retention bracket with the thumbscrew

and replace any safety hoods.

Ideal tension is the lowest tension at which the belt will not slip under peak

load conditions. Check tension frequently during the rst 24-48 hours of run-

in operation. Overtensioning shortens belt and bearing life. Keep belts free

from foreign material which may cause slipping. Never apply belt dressing

as this will damage the belt and cause early failure. Specic tools are made

to measure the tension of a V-belt drive system. A Dodge® V-Belt Tension

Tester, Browning® Belt Tension Checker or equivalent an alternative should

be used for tensioning V-belts. Check with you local belt supplier.

Belt tension is measured by applying a force perpendicular to the belt at the

center point between motor and fan sheaves. The belt should deect

1

⁄64 of

the entire span, (measured sheave centerline to sheave centerline) when

the pressure shown in the table below is applied. Because belt tension is a

function of the motor sheave diameter, it is necessary to inspect the motor