27

Maintenance

reverse. When fastening the motor mount mechanism to the torque tube,

rst insert the fasteners closest to the access panel that acts as a hinge.

After tightening this hardware, swing the motor in and attach it to the torque

tube. Due to the weight of the motor cantilevered on the hinge, the motor

mechanism may sag. When attaching to the torque tube, it may be neces-

sary to align the holes with the jacking screw shown in the image.

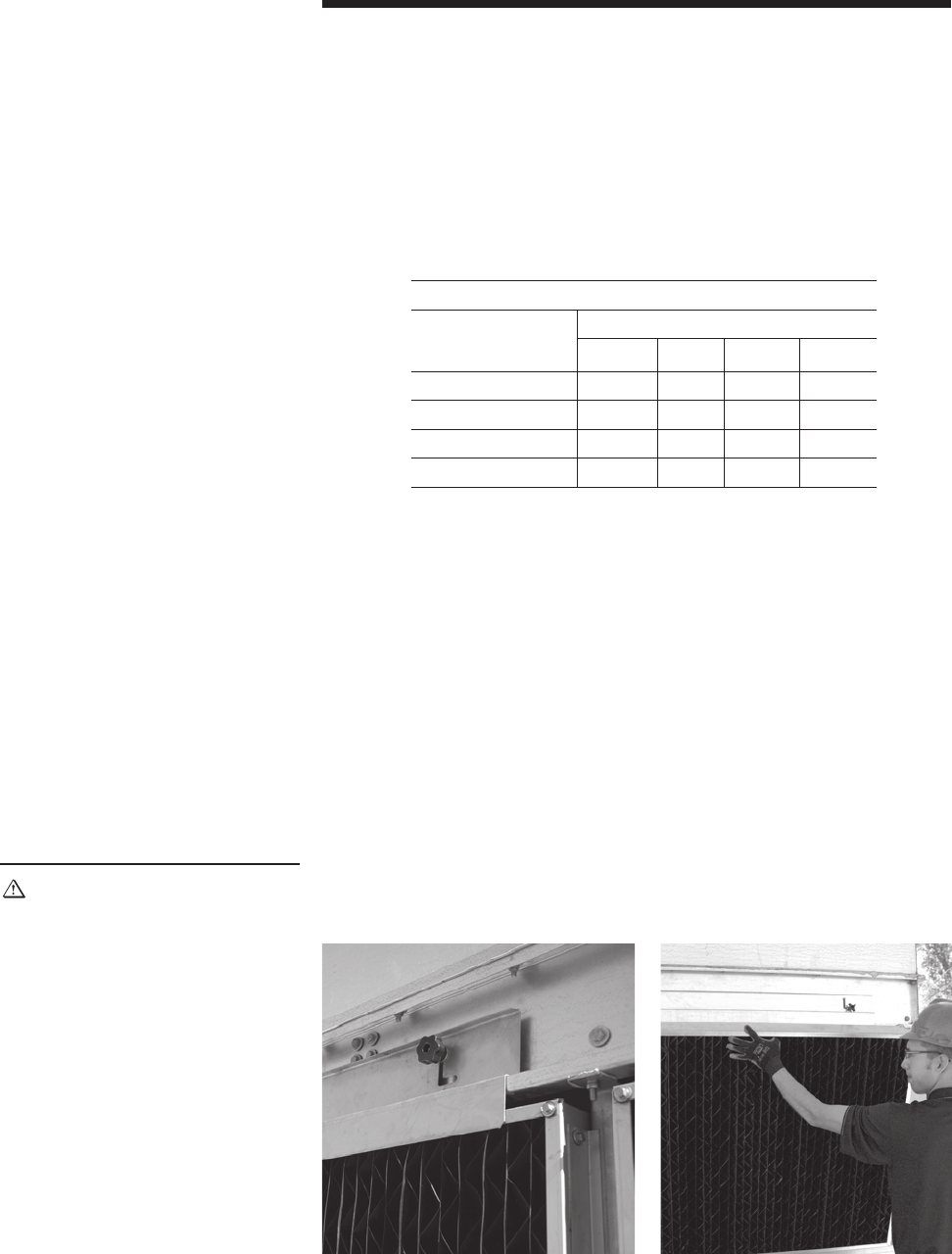

Cold Water Basin Access / Air Inlet Louver Removal

Some maintenance procedures require access to components located

in the cold water collection basin. All maintenance procedures can be

performed from the perimeter of the tower therefore there is no reason to

enter basin. To access the basin, one of the air inlet louver frames must

be removed. To remove, loosen the thumbscrews indicated in the image

below and push the louver retaining bracket up and to the left to move out

of the way of the louver frame. Tip the top of the frame out from the tower,

then remove. Louver frames are not the same size, if more than one louver

frame is removed, the original location should be noted.

Collection basing oor has uneven surfaces and has the potential to

be slippery. Care should be taken if entering the basin.

Motor Mounting Bolt Torque

Machine Bolt Size

Galvanized Stainless

ft·lb

ƒ

N·m ft·lb

ƒ

N·m

10mm 15 20 30 40

12mm 25 35 50 65

16mm 65 85 120 160

20mm 125 170 230 315

Caution