SECTION 7 I OTHER THINGS TO KNOW

SWEAT SOLDERING TIPS

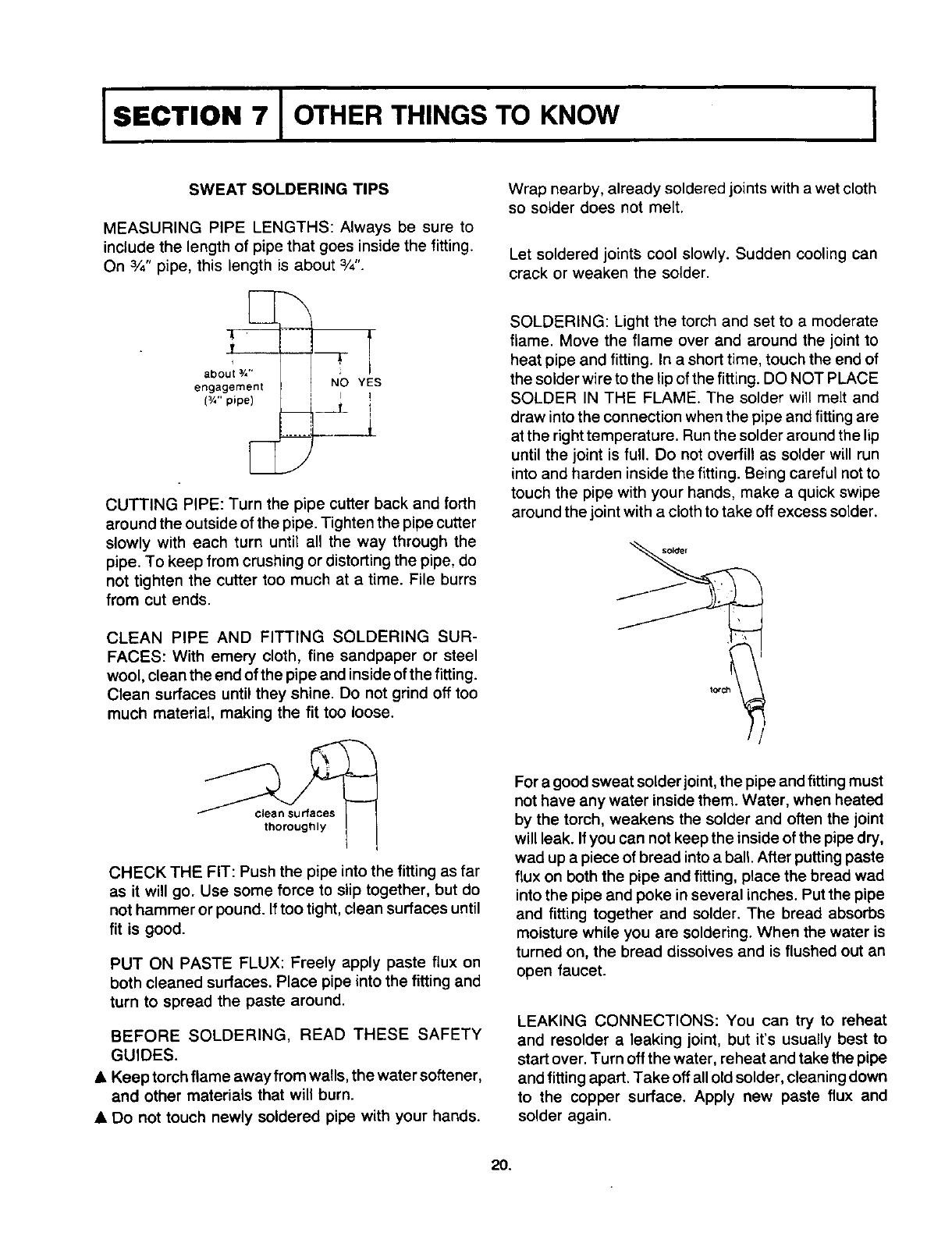

MEASURING PIPE LENGTHS: Always be sure to

include the length of pipe that goes inside the fitting.

On 3/4"pipe, this length is about 3/4".

about 3/,- : I

engagement NO YES

_i i

CUTTING PIPE: Turn the pipe cutter back and forth

around the outside of the pipe. Tighten the pipe cutter

slowly with each turn until all the way through the

pipe. To keep from crushing or distorting the pipe, do

not tighten the cutter too much at a time. File burrs

from cut ends.

CLEAN PIPE AND FITTING SOLDERING SUR-

FACES: With emery cloth, fine sandpaper or steel

wool, clean the end of the pipe and inside of the fitting.

Clean surfaces until they shine. Do not grind off too

much material, making the fit too loose.

Wrap nearby, already soldered joints with a wet cloth

so solder does not melt.

Let soldered joint_ cool slowly. Sudden cooling can

crack or weaken the solder.

SOLDERING: Light the torch and set to a moderate

flame. Move the flame over and around the joint to

heat pipe and fitting. In a short time, touch the end of

the solder wire to the tip of the fitting. DO NOT PLACE

SOLDER IN THE FLAME. The solder will melt and

draw into the connection when the pipe and fitting are

at the rig ht temperature. Run the solder around the lip

until the joint is full. Do not overfill as solder will run

into and harden inside the fitting. Being careful not to

touch the pipe with your hands, make a quick swipe

around the joint with a cloth to take off excess solder.

clean surfaces

thoroughly

CHECK THE FIT: Push the pipe into the fitting as far

as it will go. Use some force to slip together, but do

not hammer or pound. If too tight, clean surfaces until

fit is good.

PUT ON PASTE FLUX: Freely apply paste flux on

both cleaned surfaces. Place pipe into the fitting and

turn to spread the paste around.

BEFORE SOLDERING, READ THESE SAFETY

GUIDES.

• Keep torch flame away from walls, the water softener,

and other materials that will burn.

• Do not touch newly soldered pipe with your hands.

For a good sweat solder joint, the pipe and fitting must

not have any water inside them. Water, when heated

by the torch, weakens the solder and often the joint

will leak. If you can not keep the inside of the pipe dry,

wad up a piece of bread into a ball. After putting paste

flux on both the pipe and fitting, place the bread wad

into the pipe and poke in several inches. Put the pipe

and fitting together and solder. The bread absorbs

moisture while you are soldering. When the water is

turned on, the bread dissolves and is flushed out an

open faucet.

LEAKING CONNECTIONS: You can try to reheat

and resolder a leaking joint, but it's usually best to

start over. Turn off the water, reheat and take the pipe

and fitting apart. Take off all old solder, cleaning down

to the copper surface. Apply new paste flux and

solder again.

20.