Apply putty here

Tubing

Fig. 45

Fig. 44

Clamp

Insulated tubes

Insulation

Min.

5/16"

Thickness:

min. 5/16"

21

8-6. Connecting Tubing between Indoor and

Outdoor Units

a) Tightly connect the indoor side refrigerant tubing

extended from the wall with the outdoor side tubing.

(Fig. 41)

b) To fasten the flare nuts, apply specified torque as:

Table 6

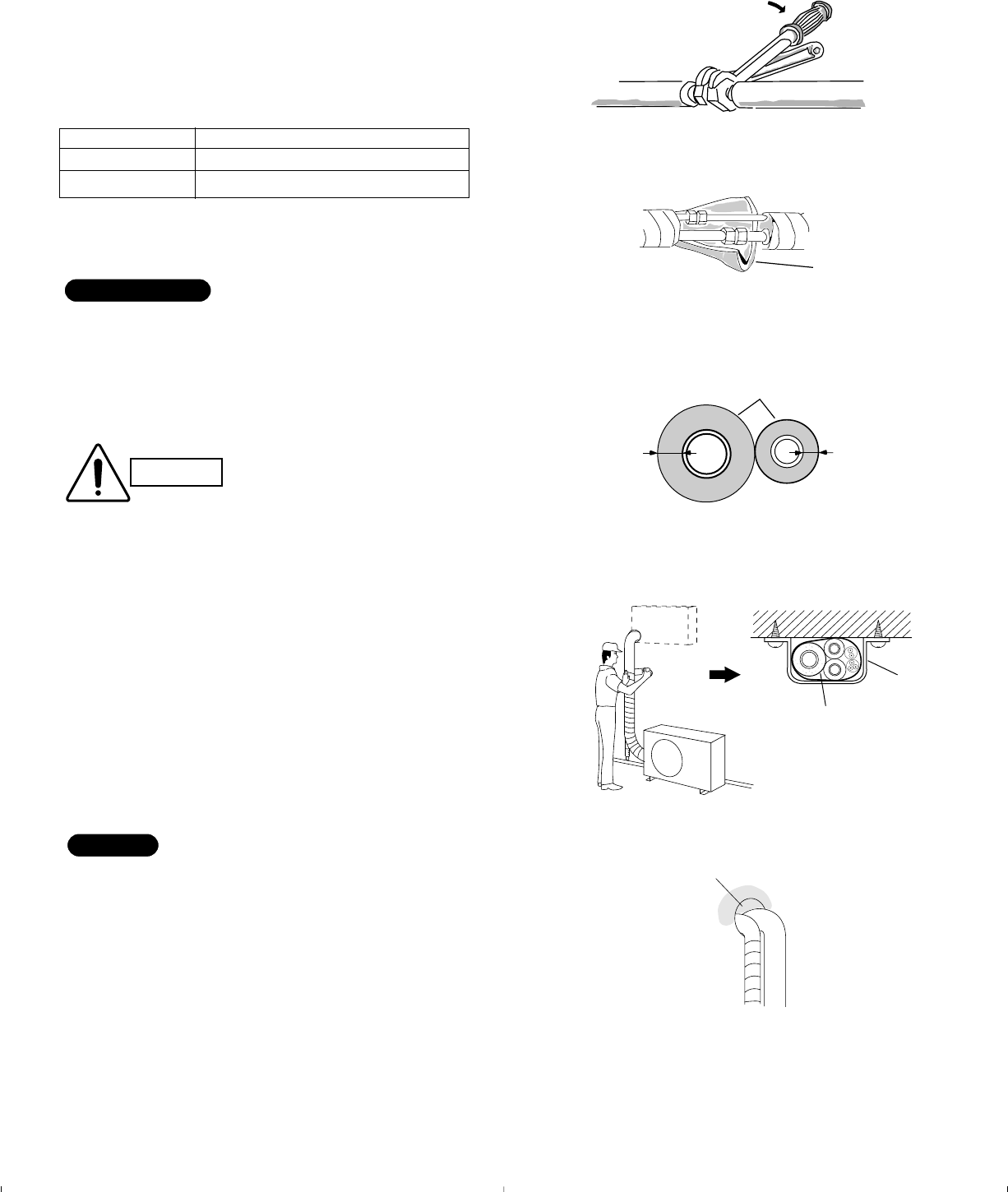

8-7. Insulation of Refrigerant Tubing

(For C2462R and CL2462R)

To prevent heat loss and wet floors due to dripping of

condensation, both tubes must be well insulated with

a proper insulation material. The thickness of the insu-

lation should be a minimum 5/16" (Fig. 43)

8-8. Taping the Tubes

(1) At this time, the 2 refrigerant tubes (and electrical wire

if local codes permit) should be taped together with

armoring tape. The drain hose may also be included

and taped together as 1 bundle with the tubing.

(2) Wrap the armoring tape from the bottom of the out-

door unit to the top of the tubing where it enters the

wall. As you wrap the tubing, overlap half of each

previous tape turn. (Fig. 44)

(3) Clamp the tubing bundle to the wall, using 1 clamp

approx. every 4 ft.

Do not wind the armoring tape too tightly since this will

decrease the heat insulation effect. Also be sure the

condensation drain hose splits away from the bundle

and drips clear of the unit and the tubing.

8-9. Finishing the Installation

After finishing insulating and taping over the tubing, use

sealing putty to seal off the hole in the wall to prevent

rain and draft from entering. Fig. 45 shows refrigerant

tubing taped separately from the drain hose.

NOTE

IMPORTANT

Indoor unit

Outdoor unit

Spanner

Torque wrench

Fig. 41

Insulation

(Field supply)

Fig. 42

Fig. 43

Tube Dia. Tightening Torque

3/8" Approx. 300 – 340 lbs.

.

in (35 – 40 N

.

m)

3/4" Approx. 870 – 1,040 lbs.

.

in (100 – 120 N

.

m)

CAUTION

After a tube has been insulated,

never try to bend it into a nar-

row curve, as this may cause

the tube to break or crack.