44

w

ith the blower suction within the tolerances spec-

ified in Table T, contact the factory. The reference

amp draw reading may help to indicate if there is

a problem with the system or if blower adjustment

i

s required.

Manifold Check

1. Check manifold gas pressure at the gas valve out-

let pressure tap (connection “D” in Fig. 48). This

pressure should read per the values in Table X for

natural and propane gas.

2. If the pressure reading differs by more than ± 0.2

in. WC, STOP – Call the factory for directions

on what to do next!

Safety Inspection

1. Check all thermostats and high limit settings.

2. During the following safety checks leave manome-

ters hooked up, check and record.

3. If other gas-fired appliances in the room are on the

same gas main, check all pressures on the MVB

with all other equipment running.

4. Check thermostats for ON-OFF operation.

5. Check high limits for ON-OFF operation.

6. While in operation, check flow switch operation.

7. Check the low gas pressure switch (if provided).

(For proper adjustment, use the attached

manometers, if available, to set pressure. The

scales on the switch are approximate only.) Low

gas pressure switch (if provided) must be set at

3.0 in. WC for natural gas and propane gas.

8. Make sure that the high gas pressure switch (op-

tional) is set to 3.0 in. WC for both natural gas and

propane gas.

Follow-Up

Safety checks must be recorded as performed.

Turn heater on. After main burner ignition:

1. Check manometer for proper readings.

2. Cycle heater several times and re-check readings.

3. Remove all manometers and replace caps and

screws.

4. Check for gas leaks one more time.

Finishing

1

. Record all data on the “Start-up Checklist” located

at the back of this manual.

2. Disconnect the manometers and reconnect the

cap on the fan pressure switch tee and reinsert the

sealing screws into the bleedle valves.

3. Start-up is complete and the heater should be

operating properly.

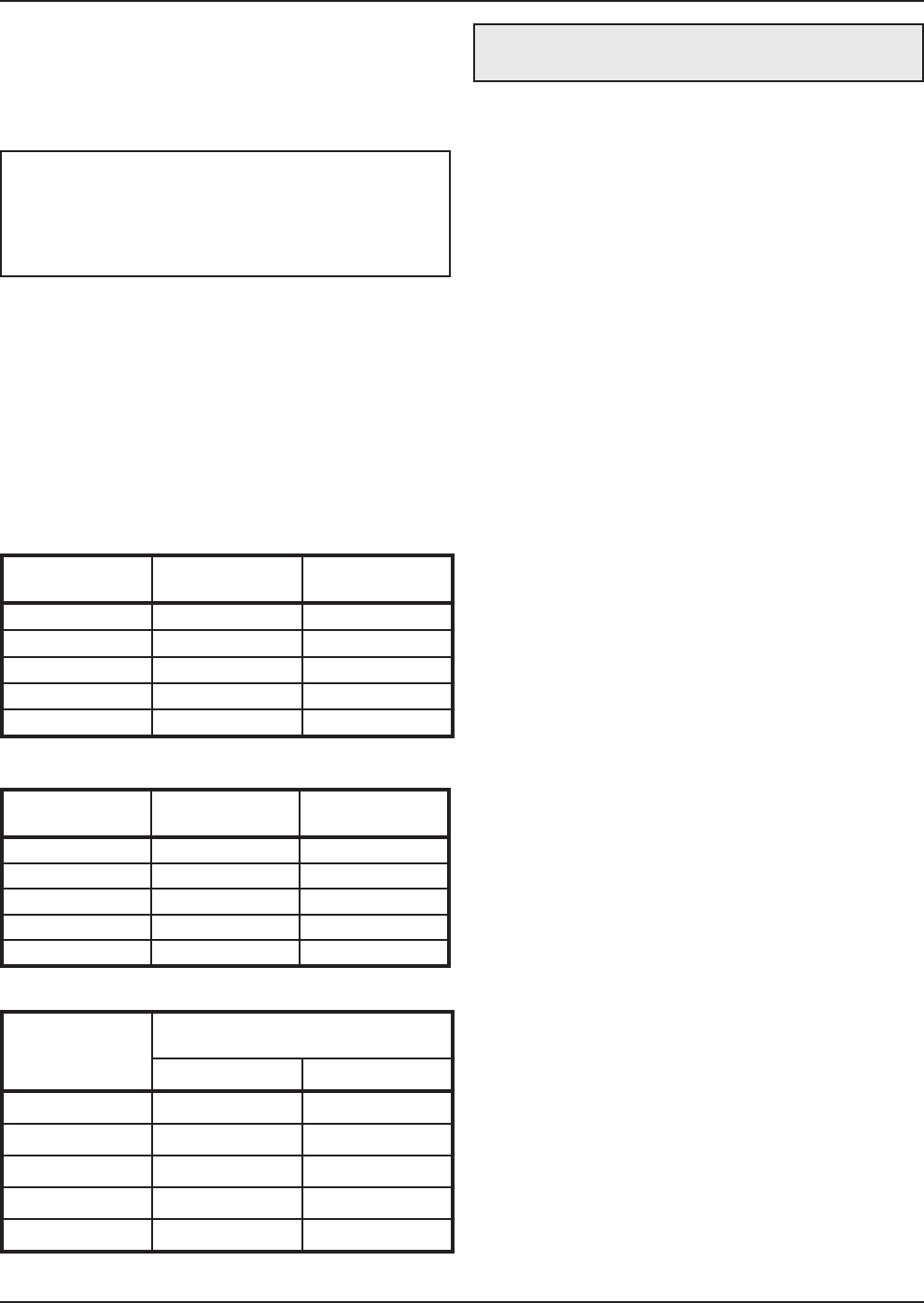

Model No.

Air Pressure

Setting (in. WC)

Setting

Tolerance

504 -2.3 ± 0.2 in. WC

754 -2.9 ± 0.2 in. WC

1104 -4.0 ± 0.2 in. WC

1504 -4.0 ± 0.2 in. WC

2004 -4.1 ± 0.2 in. WC

Table V: MVB Air Pressure Settings

Model No. Amp Draw

Setting

Tolerance

504 1.9 +0.0/-0.2

754 2.9 +0.0/-0.2

1104 5.5 +0.0/-0.2

1504 8.1 +0.0/-0.2

2004 13.0 +0.0/-0.5

Table W: MVB Amp Draw (Reference Only)

Model No.

Manifold Gas Pressure Setting

High Fire Values (in. WC)

Natural Gas Propane Gas

504 -0.1 -0.1

754 -0.4 -0.1

1104 -1.0 -0.2

1504 -2.4 -0.6

2004 -1.0 -0.5

Table X: MVB Manifold Pressure Settings

NOTE: Most commercially available amp probes

are not accurate enough and/or are not shielded well

enough to read accurately in the heater

environment. Blower amp draw readings are for

reference only.

CAUTION: Special manifold and air settings may

be required.