4. Place in operation the appliances being inspected.

Follow the manufacturer’s instructions for lighting

each appliance. Adjust thermostat so appliance

w

ill operate continuously.

5

. Check the pressure at a pressure tap located 12

in. above the bottom joint of the first vertical vent

pipe. Pressure should be anywhere between -0.01

and -0.08 in. WC.

6. After it has been determined that each appliance

remaining connected to the common venting sys-

tem properly vents when tested as outlined above,

return doors, windows, exhaust fans, fireplace

dampers and other gas burning appliances to their

previous conditions of use.

7. Any improper operation of the common venting

system should be corrected so that the installation

conforms with the NFGC (U.S.) or B149 (Canada).

When re-sizing any portion of the common venting

system, the common venting system should be re-

sized to approach the minimum size as

determined using the appropriate tables in Ap-

pendix G in the NFGC (U.S.) or B149 (Canada).

Engineered Vent Systems

Table M provides boiler discharge vent volumes of flue

products at full fire for the calculation of appropriate

vent sizing for common venting.

27

NOTE: Data for 100% firing rate.

Table M: Typical Volume of Flue Products

WARNING: Vent connectors serving any other

appliances shall not be connected into any portion of

mechanical draft systems operating under a positive

pressure. If an MVB heater is installed to replace an

existing heater, the vent system MUST be verified to

be of the correct size and Category. If it is NOT, it

MUST be replaced.

NOTE: For extractor sizing, typical CO

2

levels are

8.5% for natural gas and 9.5% for LP gas and flue

temperature of 350° F.

M

odel

No.

V

ent Size

(in.)

Volume of

Flue Products

(CFM)

504 8 170

754 10 260

1104 10 380

1504 12 510

2004 14 680

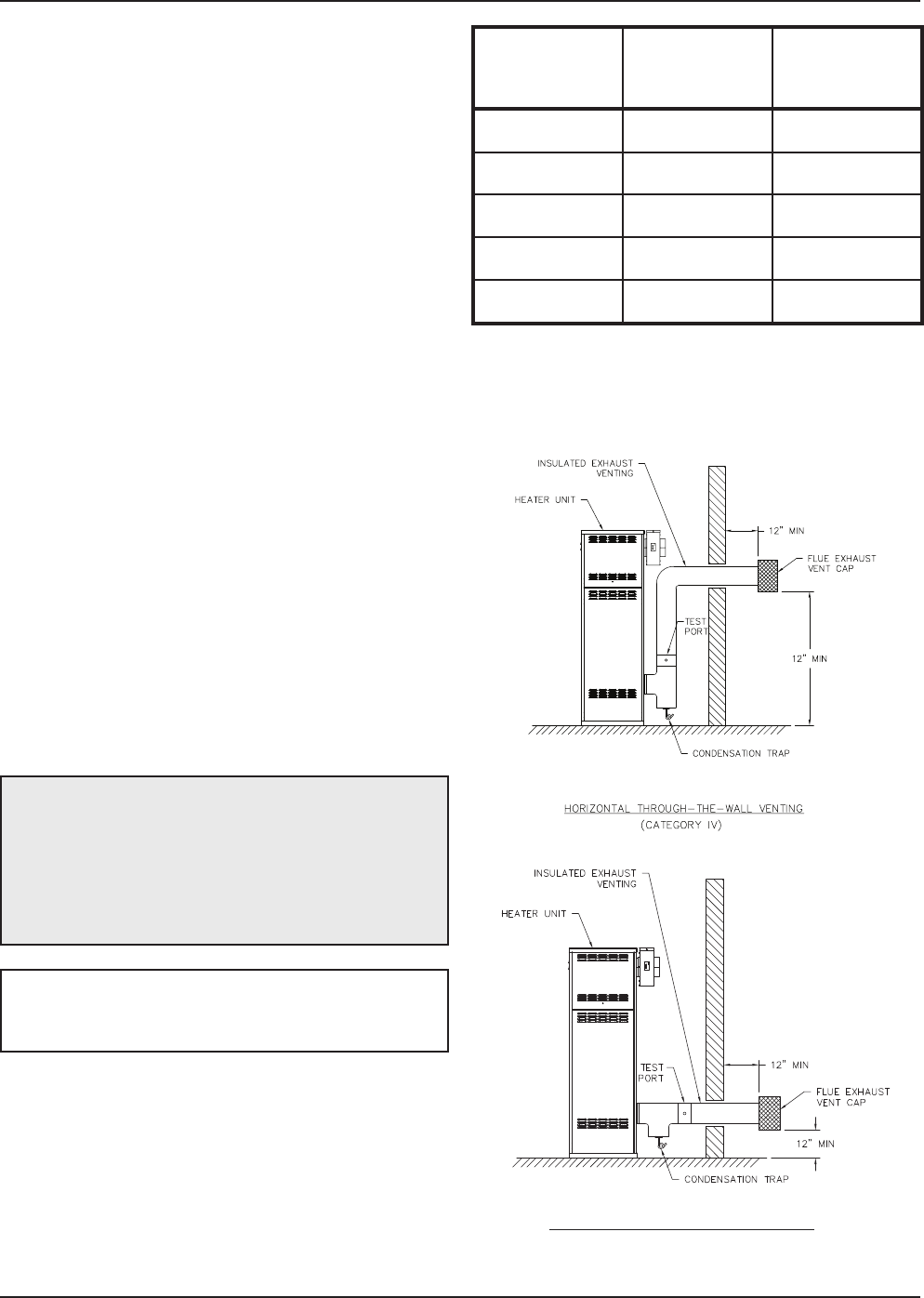

Horizontal Through-the-Wall Direct

Venting (Category III)

Fig. 25: Horizontal Through-the-Wall Venting

OPTIONAL HORIZONTALTHROUGH-THE-WALL VENTING

(CATEGORY IV)

Fig. 26: Alt. Horizontal Through-the-Wall Venting