42

Preparation

Check Power Supply

With multi-meter at incoming power, check voltage

between:

Hot - Common (≈120 VAC)

Hot - Ground (≈120 VAC)

Common - Ground (< 1 VAC)

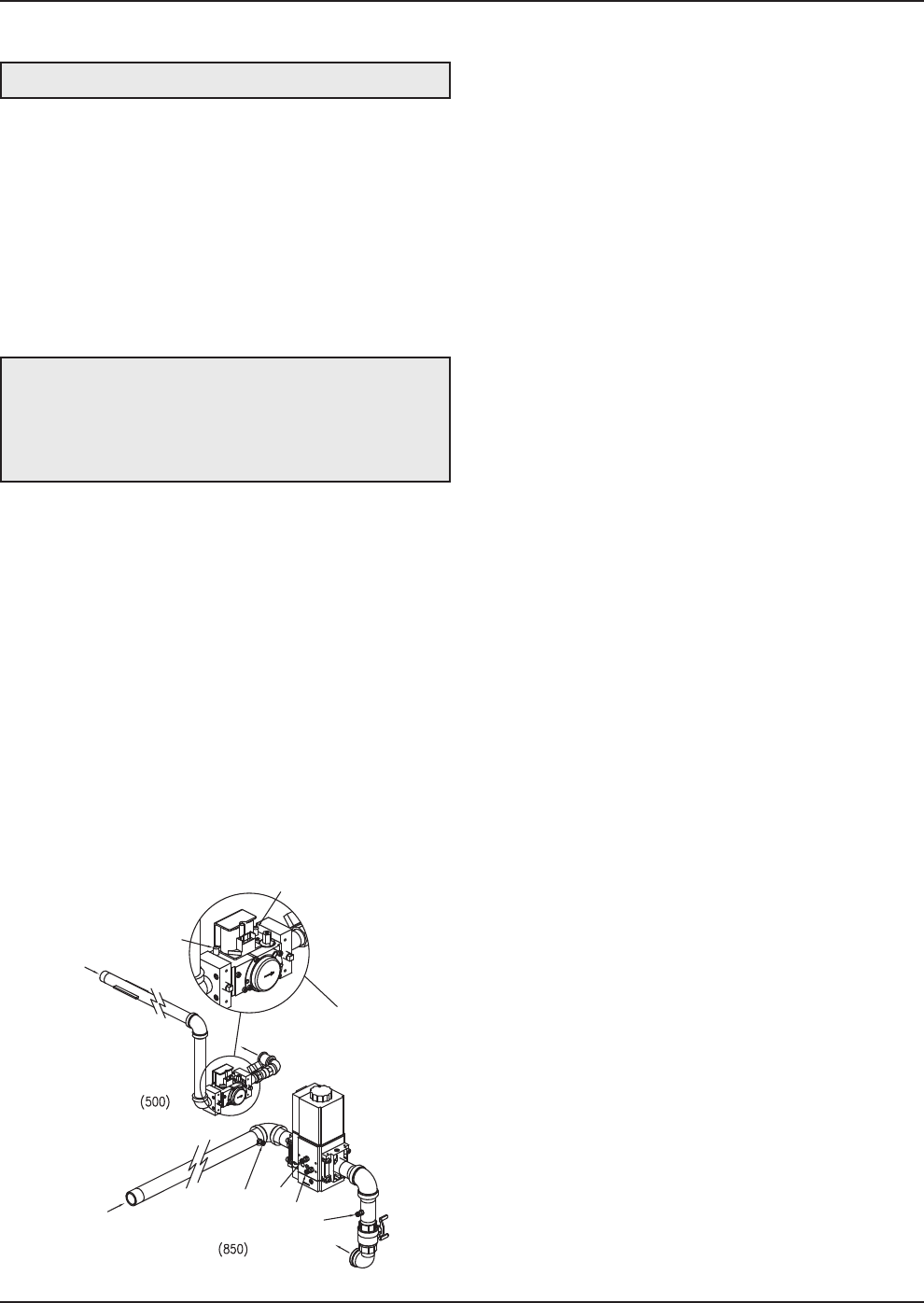

Attach Manometers to Measure Pressures

1. Turn off main gas valve.

2. Attach (1) 12” scale manometer to an upstream

bleedle valve on the gas supply pipe to the boiler

(Measure point “A” in Fig. 35).

3. Attach (1) 12” scale manometer to the manifold

pressure tap located downstream of the valve

(Measure point “D” in Fig. 35).

4. Attach (1) 12” scale manometer to the tapping on

the filter box. Pull black cap from air pressure

switch tee and connect the manometer. NOTE:

Retain caps for reinstallation later.

WARNING: If Common - Ground is > 1 VAC,

STOP: Contact electrician to correct ground failure.

Failure to do this may burn out 120V-24V

transformer, or may cause other safety control

damage or failure.

Start-Up

1. Turn power on.

2. Turn on the boiler, approximately 5 seconds after

the blower starts, the igniter should start to spark

(observable through the observation port located

at the front, bottom of the boiler) and the gas valve

will open. Look into the sight glass located at the

bottom of the front panel to check igniter opera-

tion.

3. The boiler ignites at 3000 RPM (as indicated on

the LCD display of the user interface).

4. This boiler is equipped with a standard four-try

ignition module, it will try for ignition up to four

times before going into lockout. If the boiler is

equipped with the optional single-try ignition mod-

ule, it will try for ignition one time before going into

lockout.

5. Wait until the controller indicates 100% on the fir-

ing rate display screen. This will take several

minutes if step modulation is enabled.

Blower Check

1. Check the high and low fire fan speed on the user-

interface. Enter the service mode by pressing the

UP arrow key and ENTER/MENU key simultane-

ously for 1 second. Verify that the min. and max.

fan speeds match Table R on the following page.

2. Note the high fire air intake pressure on the filter

box and compare to Table Q. Excessively high

pressures indicate an obstruction in the air intake

or undersized/too long air intake ducting. With a

clean air filter in place, record the intake air pres-

sure setting on the start-up checklist. Replace the

filter when the intake air pressure increases by

A

A

D

D

B

C

GAS

GAS

TO BURNER

TO BURNER

MODEL 300 VALVE

USES SAME POINTS

A & DAS MODEL 500

Fig. 35: Gas Pressure Measurement Locations

Check Gas Supply Pressure

1. Slowly turn on main gas shut-off valve.

2. Read the gas supply pressure from the manome-

ter; minimum supply pressure for natural gas is 4.0

in. WC, recommended supply is 7.0 in. WC, mini-

mum supply pressure for propane gas is 4.0 in.

WC, recommended supply is 11.0 in. WC (dynam-

ic readings, full fire input).

3. If the gas pressure is greater than 14.0 in. WC,

turn off the main gas shut-off valve.

WARNING: Do not turn on gas at this time.