23

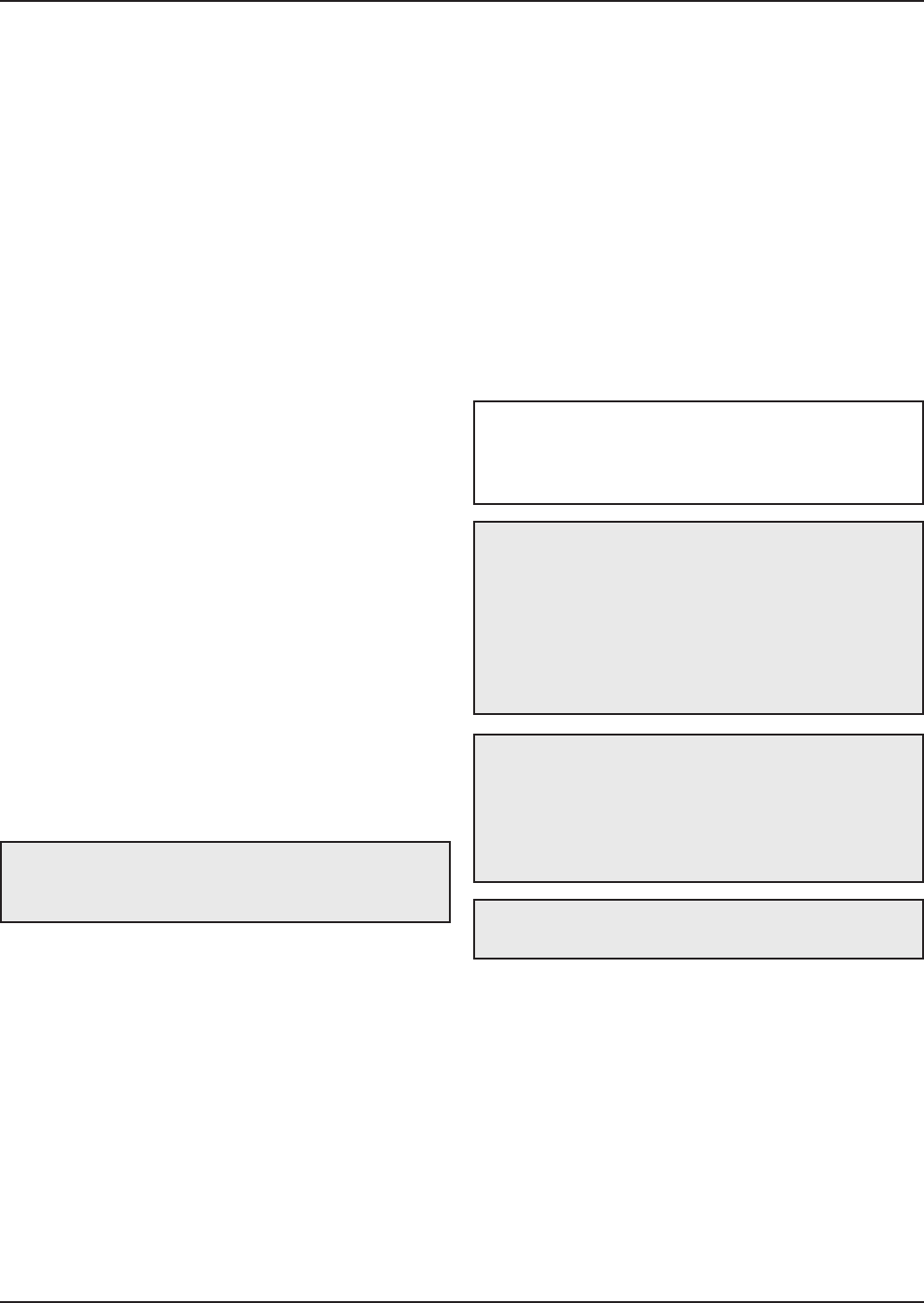

Cascade Follower Pump

and Sensor Wiring

1

. Connect the boiler pump to the terminals marked

BOILER PUMP NEUT (#6), BOILER PUMP HOT

(

#5), and GROUND (#4) at the rear terminal strip.

2. If you are using an indirect fired water tank con-

nected directly to the follower boiler, connect the

pump for it to the terminals marked DHW PUMP

NEUT (#8), DHW PUMP HOT (#7), and GROUND

(#3) at the rear terminal strip.

If you desire, an alarm bell or light can be connected

to the alarm contacts of the follower boiler. Optionally,

the normally-closed alarm contact may be used to turn

a device off if the boiler goes into lockout mode. The

alarm contacts are rated 5 amps at 120 VAC.

To connect an alarm device, connect the power for the

device to the ALARM COM terminal. Connect the

alarm device hot wire to the ALARM NO terminal.

Connect the neutral or return of the alarm device to the

neutral or return of the power for the alarm device.

To connect a device that should be powered off during

a boiler lockout condition, follow the same instructions

as above except use the ALARM NC terminal rather

than the ALARM NO terminal.

Note that in a cascade system the alarm output of the

boiler addressed as #1 will also be active if the master

boiler has a lockout condition. The alarm output of boil-

ers addressed as 2–7 will only sound if a lockout

condition occurs on that specific boiler.

Venting

General

Appliance Categories

Heaters are divided into four categories based on the

pressure produced in the exhaust and the likelihood of

condensate production in the vent.

Category I – A heater which operates with a non-pos-

itive vent static pressure and with a vent gas

temperature that avoids excessive condensate pro-

duction in the vent.

Category II – A heater which operates with a non-pos-

itive vent static pressure and with a vent gas

temperature that may cause excessive condensate

p

roduction in the vent.

C

ategory III – A heater which operates with a positive

vent pressure and with a vent gas temperature that

avoids excessive condensate production in the vent.

Category IV – A heater which operates with a positive

vent pressure and with a vent gas temperature that

may cause excessive condensate production in the

vent.

See Table K for appliance category requirements.

Use only approved PVC or CPVC vent materials (in

Canada, ULC-S636 approved plastic materials must

be used) or special gas vent pipes listed for use with

Category IV gas burning heaters, such as the AL29-4C

stainless steel vents offered by Heat Fab Inc. (800-

772-0739), Protech System, Inc. (800-766-3473),

Z-Flex (800-654-5600) or American Metal Products

(800-423-4270). Pipe joints must be positively sealed.

Follow the vent manufacturer’s installation instructions

carefully. Vent installations shall be in accordance with

Part 7, Venting of Equipment, of the NFGC, ANSI

Z223.1/NFPA 54, Section 7, Venting Systems and Air

Supply for Appliances, of the B149 Code, or applicable

provisions of the local building codes.

NOTE: For additional information on appliance

categorization, see the ANSI Z21.13 Standard and

the NFGC (U.S.), or B149 (Canada), or applicable

provisions of local building codes.

CAUTION: Condensate drains for the vent piping

are required for installations of the XFyre. Follow

vent manufacturer instructions for installation and

location of condensate drains in the vent.

Condensate drain traps must be primed with water to

prevent gas flue leak and must be routed to an

appropriate container for neutralization before dis-

posal, as required by local codes.

CAUTION: Proper installation of flue venting is

critical for the safe and efficient operation of the

boiler.

WARNING: Contact the manufacturer of the vent

material if there is any question about the appliance

categorization and suitability of a vent material for

application on a Category IV vent system. Using

improper venting materials can result in personal

injury, death or property damage.

CAUTION: Raypak recommends the use of a con-

densate neutralizer, sales order option Z-12.