R

November 22, 2011

7036-135G

Page 11

Mt. Vernon Pellet Insert (AE)

• The fireplace must not be altered, except for the

exceptions listed below. Do not remove the bricks and

mortar from the existing fi replace.

The following modifi cations are permissible:

• Removal of damper or locked in open position

• Removal of smoke shelf or baffl e

• Removal of ember catches

• Removel of fi re grate

• Removal of view screen/curtain

• Removal of doors

• External trim pieces which do not affect the operation

of the fi replace may be removed providing they can be

stored on or within the fi replace for reassembly if the insert

is removed.

• The permanent metal warning label provided must be

attached to the back of the fi replace, with screws or

nails, stating that the fi replace may have been altered to

accommodate the insert, and must be returned to original

condition for use as a conventional fi replace. Figure

11.1

• If the hearth extension is lower than the fi replace opening,

the portion of the insert extending onto the hearth must

be supported.

• Manufacturer designed adjustable support kit can be

ordered from your dealer.

• Final approval of this installation type is contingent upon

the authority having jurisdiction.

I. Altering the Factory-Built Fireplace

WARNING! Risk of Fire!

Follow venting manufacturer’s clearances and instructions

when installing venting system.

NOTICE: In Canada when using a factory-built chim-

ney it must be safety listed, Type UL103 HT (2100

o

F)

[1149

o

C] CLASS “A” or conforming to CAN/ULC-

S629M, STANDARD FOR 650

o

C FACTORY-BUILT

CHIMNEYS.

NOTE: Refer to chimney liner manufacturer for recom-

mendations on supporting the liner. Installation into

fi replaces without a permit will void the listing

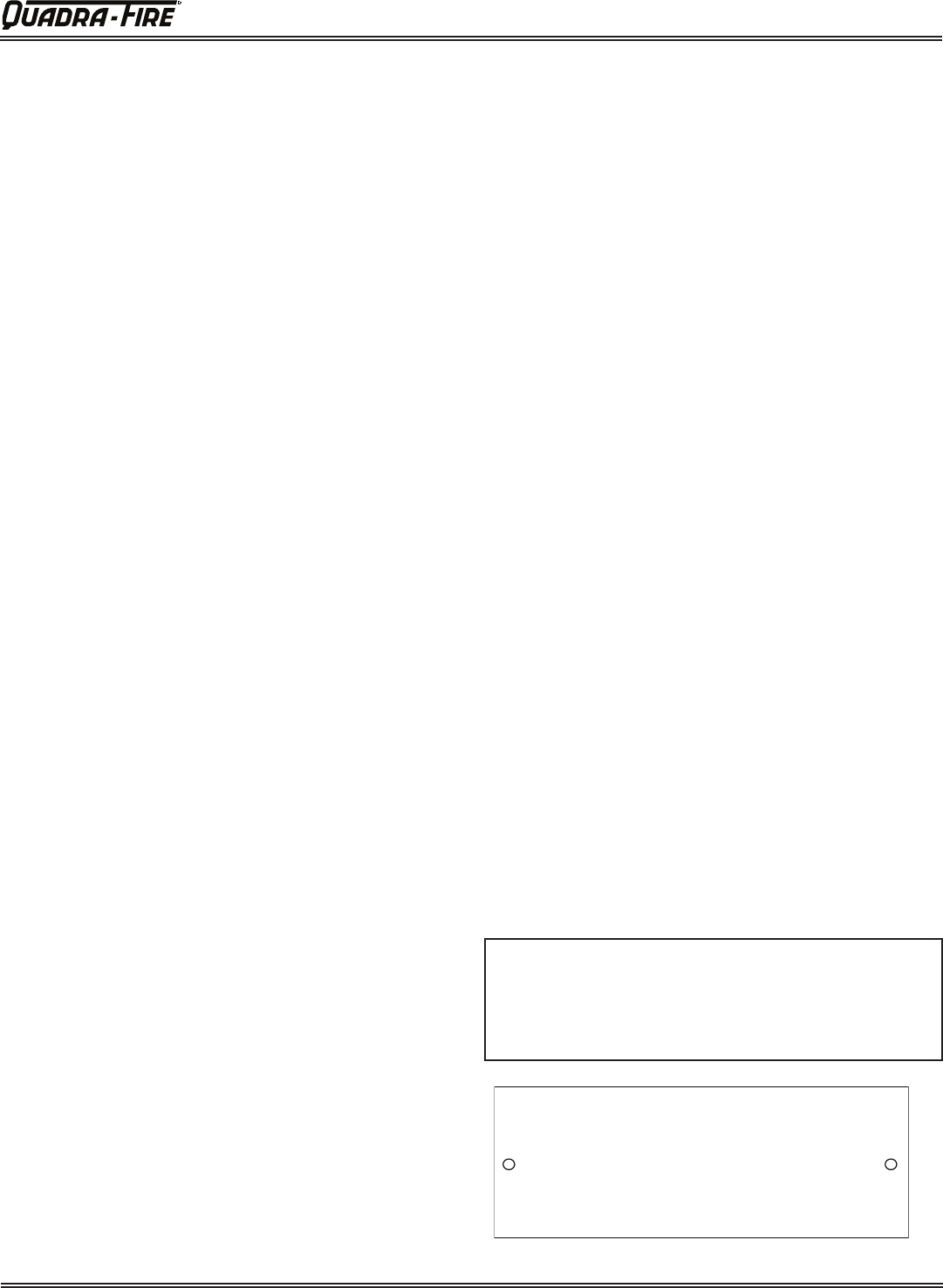

250-2061

WARNING

THIS FIREPLACE MAY HAVE BEEN ALTERED

TO ACCOMMODATE AN INSERT. IT MUST BE

RETURNED TO ITS ORIGINAL CONDITION

BEFORE USE AS A SOLID FUEL BURNING

FIREPLACE.

250-2061

Figure 11.1

H. Prefabricated Metal Chimney

The chimney can be new or existing, masonry or prefabricated

and must meet the following minimum requirements:

• Must be minimum 6 inch (152mm) inside diameter of

high temperature chimney listed to UL 103 HT (2100

o

F)

or ULC-S628.

• Must use components required by the manufacturer for

installation.

• Must maintain clearances required by the manufacturer

for installation.

• Refer to manufacturers instructions for installation

•This insert is listed to ASTM E 1509 Standard and is

approved for installation into listed factory-built zero

clearance fi replaces listed to UL 127 conforming to the

following specifi cations and instructions:

•The original factory-built clearance fi replace chimney

cap must be re-installed after installing the approved

chimney liner meeting type UL 103 HT requirements

(2100°F) per UL 1777.

•If the chimney is not listed as meeting HT requirements,

or if the factory built fi replace was tested prior to 1998, a

full height listed chimney liner must be installed from the

appliance fl ue collar to the chimney top.

•The liner must be securely attached to the insert fl ue collar

and the chimney top.

•The air fl ow of the factory-built zero-clearance fi replace

system must not be altered. The fl ue liner top support

attachment must not reduce the air fl ow for the existing

air-cooled chimney system.

•No dilution air is allowed to enter the chimney.

1. Secure the fi replace damper in the open position. If

this cannot be accomplished, it will be necessary to

remove the damper

2. Seal damper area of chimney around chimney

connector with a high temperature sealant or seal

insert against the face of the fi replace.

3. Both methods must be removable and replaceable

for cleaning and re-installation.