Page 21

Gas supply piping is to be sized and installed properly in order to provide a

supply of gas sufficient to meet the maximum demand without undue loss of

pressure between the meter and the boiler. Consult with the National Fuel Gas

Code ANSI Z223.1 for proper sizing of gas piping for various lengths and diameters.

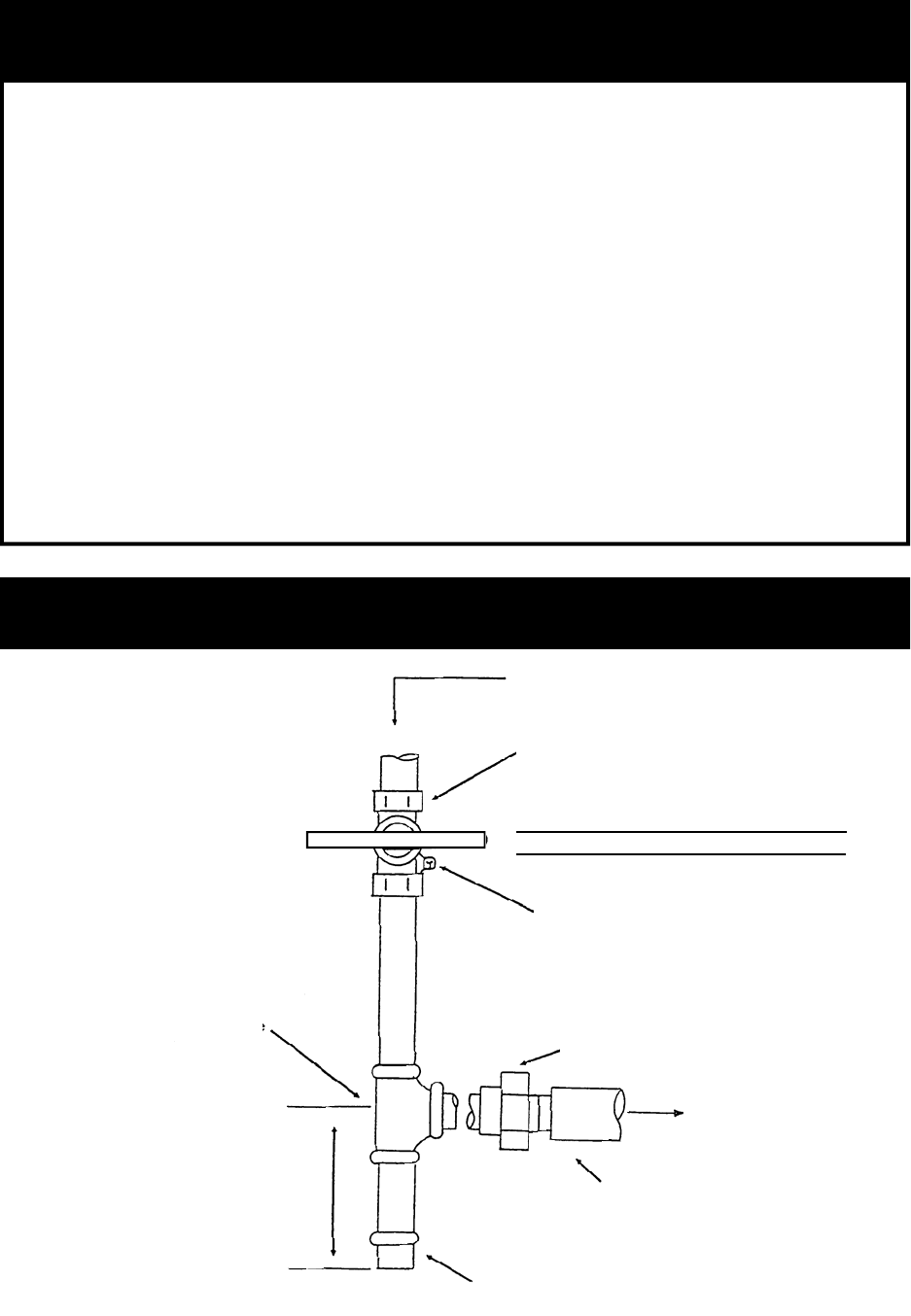

Locate a drop pipe adjacent to, but not in front of the boiler. Locate a tee in the

drop pipe at the same elevation as the gas inlet connection to the boiler. Extend the

drop line with a nipple towards the floor and cap to form a sediment trap. Install a

shut off valve before the tee with sediment trap and a union after the tee before the

combination gas valve.

When installing the boiler, make sure a pipe compound resistant to the action of

liquefied petroleum is used. Check piping for leaks. Always check leaks with a water

and soap solution. DO NOT USE A FLAME FOR CHECKING GAS LEAKS

The boiler and its individual shut-off valve must be disconnected from the gas

supply piping during any pressure testing of that piping at test pressures in excess of

1/2 psi.

To check for gas

leaks, use a gas detec-

tor or apply a soap

solution to the joints.

DO NOT USE AN

OPEN FLAME!

Direction of flow

Manual Shutoff Valve

Height of shutoff valve above ground

level to conform to local codes, if any.

Note: Massachusetts state code requires

gas shutoff to be a tee handled gas cock.

Pressure Gauge Port

(1/8” NPT plugged)

1” X 1” X 3/4” Tee

Male Union 3/4” NPT

Burner Gas Train

Pipe Cap

3” MINIMUM

9. Gas Line Piping

INSTALLATION OF SEDIMENT TRAP AND BURNER SUPPLY