19

PV500-46U 06/12

The following vent information is provided for use in design calculations, if needed.

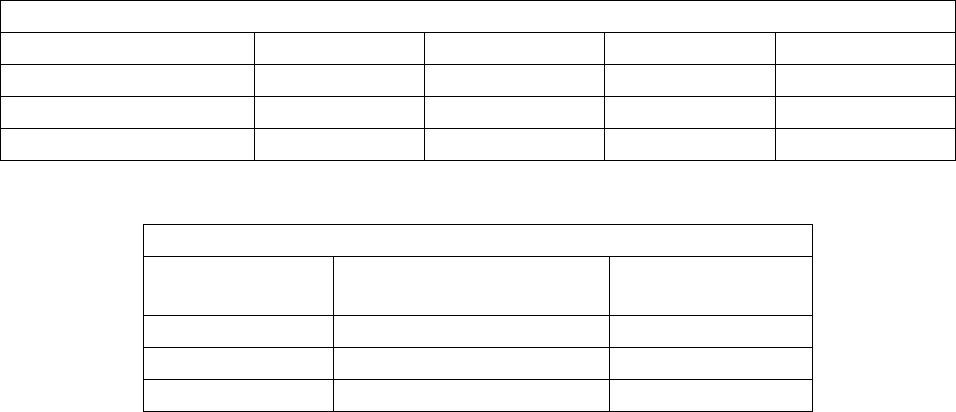

Venting Specifications

Input Mbtu

Products of Combustion

Volume (cfm)

Max Vent

Press. “W.C.

1500 350 1.7

1800 420 2.0

2000 467 2.0

9.4 CPVC Vent System Design, Construction and Assembly:

The Power VT Plus water heater can be vented either vertically, through a ceiling or roof, or horizontally through a

wall. The solid CPVC, (CPVC not allowed on models with “SANI” in the model number) or stainless steel venting

listed by a nationally recognized testing laboratory for Category IV positive pressure gas appliance venting can be

routed to the outdoors in any direction, from the flue outlet of the water heater economizer, except down. The vent

must be installed and supported every four feet to slope downward toward the water heater vent connection with at

least ¼ inch drop per linear foot of horizontal vent run, to allow proper drainage of accumulated condensation.

1. Read and follow the information, instructions and warnings in “VENTING” section.

2. Do not insulate the plastic vent pipe.

3. Clean and deburr all solid CPVC (plastic pipe not allowed for venting models with “SANI” in the model number)

pipe ends and the joint area and trial assemble the vent before joining with CPVC cement, following the CPVC

cement manufacturer’s instructions for making sound air and water tight joints.

4. Dry-fit a solid 6” CPVC pipe into the female economizer flue outlet. Remove the pipe and apply a liberal coating

of room temperature vulcanizing (RTV) adhesive to the inside of the stainless steel economizer flue outlet and

to the outside of the plastic pipe. Before the RTV sets, slide the plastic coupling or elbow back into the RTV

coated economizer flue outlet while rotating the pipe approximately 1/8 of a turn. Inspect and apply RTV to the

inside and outside of the plastic to stainless steel joints to provide a continuous water and gas tight assembly.

5. Drill a pilot hole through the top of the stainless steel economizer flue outlet and into the 6” CPVC pipe and

attach with a sheet metal screw (stainless steel screws are recommended). Repeat this step adding a sheet

metal screw to each side of this economizer flue outlet to positively attach the pipe to the flue outlet. Do not drill

or use a screw in the bottom of the flue connector or pipe, as condensate might drip from this point.

6. Vent support – The vent system must be supported at intervals no greater than four feet, to prevent sagging

and distortion.

7. Testing for leaks - All joints in the vent system must be air and water tight. After the vent is assembled, close

the end of the vent with a taped plastic bag or some other temporary closure. With the gas supply turned off,

energize the combustion blower to apply air pressure to the vent system. Spray each joint and vent connection

with commercially available leak detection liquid to confirm no air is escaping from any point. Repair any leaks

and retest. After testing is complete, de-energize the combustion blower, wipe clean the leak detection liquid

and REMOVE the temporary vent closure.

Vent Fitting Equivalent Length

Vent Pipe: 6” Vent 7” Vent 8” Vent 9” Vent

90º Elbow 8 feet 9 feet 10 feet 11 feet

90º Long Radius Elbow 5 feet 5 feet 5 feet 6 feet

45º Elbow 5 feet 5 feet 5 feet 5 feet