9

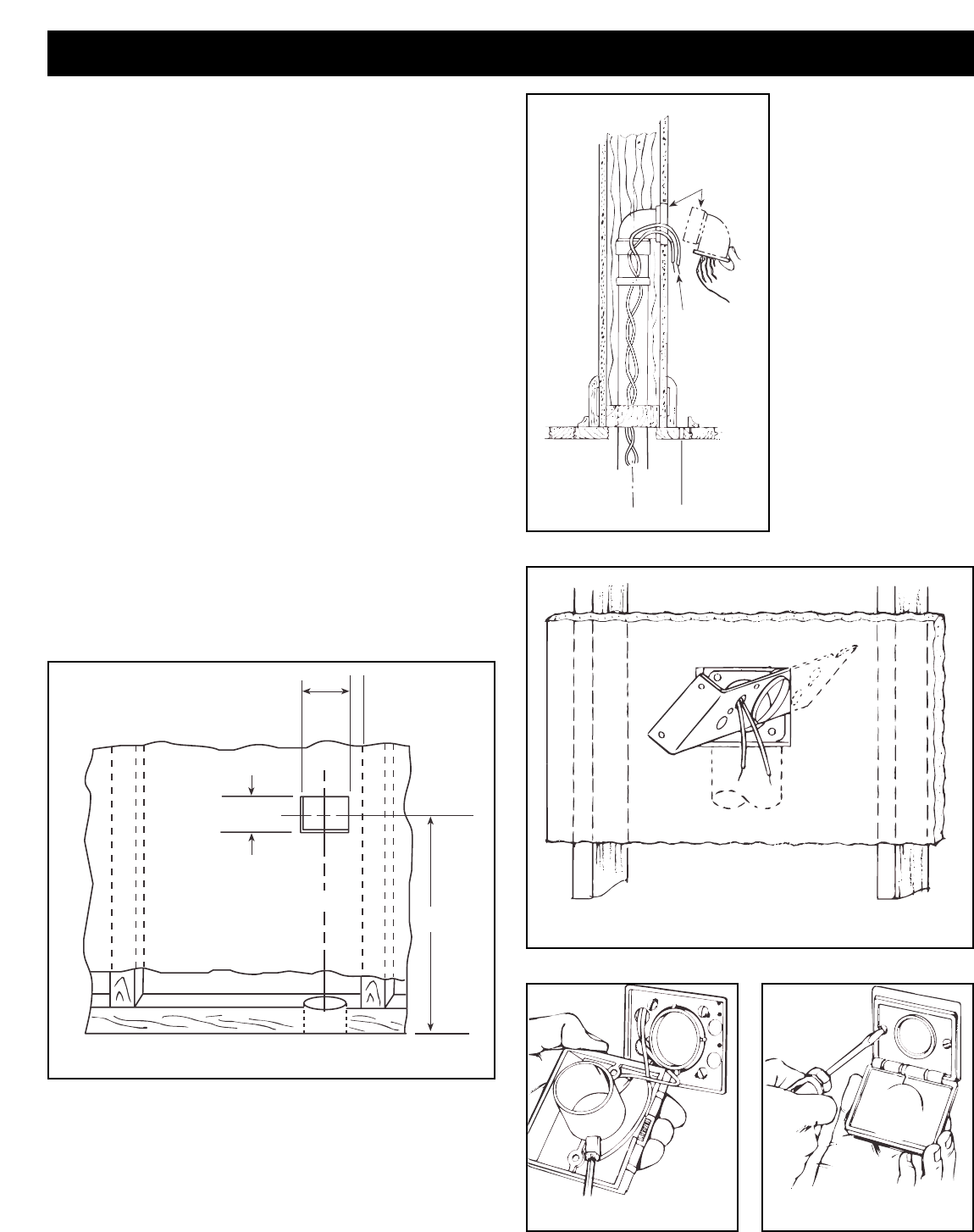

4. Be sure tubing hole is centered in sole plate and directly in

line with proposed wall inlet cutout.

NOTE: If 330 wall inlet is being used refer to Model 330 Wall

Inlet Installation on next page.

5. If area is clear, cut an inlet opening in the wall approximately

18" above the floor. Make sure wall opening and 2

1

⁄2" tube

hole line up (Figure 25).

6. Cut a length of tubing that will extend from inlet opening to a

point below floor level (or above ceiling level in attic

installation). Tape low voltage wire to tube and insert tube

through predrilled hole to a level opposite the wall opening.

7. Apply cement to tube and install flanged wall fitting. Make

sure fitting is well seated and sealed (Figure 26).

8. Remove plaster frame from mounting bracket. Pull low

voltage wire through hole in bracket and insert bracket into

cutout. Secure bracket to flanged fitting with four screws

provided. Be sure seal is secure between flange fitting and

mounting bracket (Figure 27).

9. Starting from farthest wall inlet location, install each inlet as

described above. Working back toward power unit, connect

each branch line into main trunk line. Complete low voltage

wiring as main trunk line is continued back to power unit.

10. Attach the low voltage wires to terminal screws on back of

wall inlet (Figure 28).

11. Insert wall inlet into bracket and secure with the two screws

provided (Figure 29).

12. Mount power unit and complete wiring. See page 7.

2

1

/2"

2

9

/16"

3

1

/16"

18"

FIGURE 25

FIGURE 27

FIGURE 28 FIGURE 29

LOW

VOLTAGE

WIRING

FLANGED

FITTING

FIGURE 26

NOTE: If the wall for mounting the Model 360 inlet is less

than

1

⁄2", a spacer must be used. See Figure 5A as a

guide.