8

INSTALLATION IN EXISTING CONSTRUCTION

LAYOUT AND PLANNING

The general layout and planning and the component locations

are the same for existing construction.

See pages 2 and 3.

LOCATING ACCESS KEYS

Unless your home is a ranch-style house where a single trunk

line can run directly through the attic or basement, you should

first investigate your house to find the “key” to running your

tubing from level to level. What you're looking for is an accessible

area that is free from obstructions and will accommodate the

2" tubing.

Let's say, for example, you have a two-story house and you

want to locate the power unit in the basement. The first floor

inlets can easily be connected to a trunk line which runs along

the basement ceiling. However, you can't find interior walls on

both the first and second floors which line up and are free from

obstacles. How do you get from the basement to the attic?

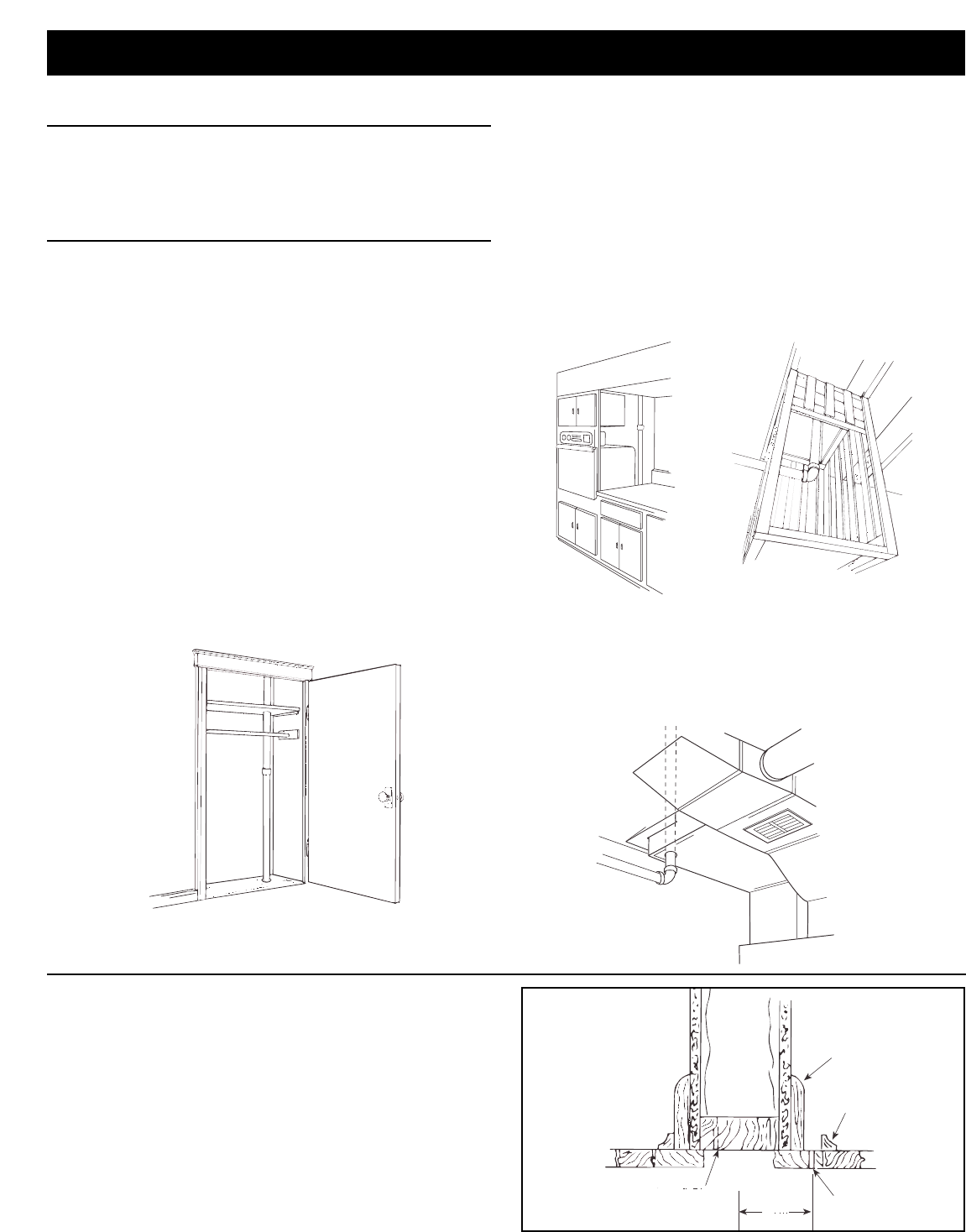

Some of the “keys” you might find in your home are illustrated

here.

Stacked Closets. Many homes will have an upstairs closet

located directly above a downstairs closet. It is easy to run the

tubing from one floor level to another inside these stacked

closets. In these installations the tubing is often left exposed

inside the closets. See Fi

Built-In Appliances. In a home where the kitchen features

built-in appliances, you'll often find a hollow space behind these

appliances. If this space lines up with an obstruction-free interior

wall above or a closet, this might be a “key” to your installation.

In a ranch-style home, this “key” would provide access to run

tubing from a basement located power unit to an attic trunk line.

You may also want to consider running exposed tubing through

cabinets or cupboards. See Figure 22.

Laundry Chute. Pictured here is tubing run from the basement

to the attic through a laundry chute. A dumb-waiter would serve

the same purpose. See Figure 22.

Cold-Air Return. A cold-air return often provides a straight run

from basement to other levels of the house. The ductwork is

easily cut for access. Seal around the tube when completing the

installation. See Figure 23.

FIGURE 21

FIGURE 22

FIGURE 23

WALL INLET INSTALLATION

Use the following procedures for installation in existing

construction.

1. See Figure 24. A small “Pilot” or “Locating” hole can be

drilled behind baseboard toe strip to determine proper

location of 2

1

⁄2" diameter tubing hole in sole plate.

2. Measure the total thickness of the wall, including baseboard.

One half of this wall thickness measured from the Pilot Hole

(dimension “X”) will determine the proper location of the 21/2"

tubing hole in the sole plate.

3. See Figure 24. Once desired inlet locations have been

determined, cut a 2

1

⁄2" hole in soleplate directly in line with

proposed inlet location. Check through tubing hole to be sure

no obstruction exists.

BASEBOARD

TOE STRIP

PILOT HOLE

“X”

SOLE PLATE

FIGURE 24