6

W415-0580 / C / 04.07.08

*

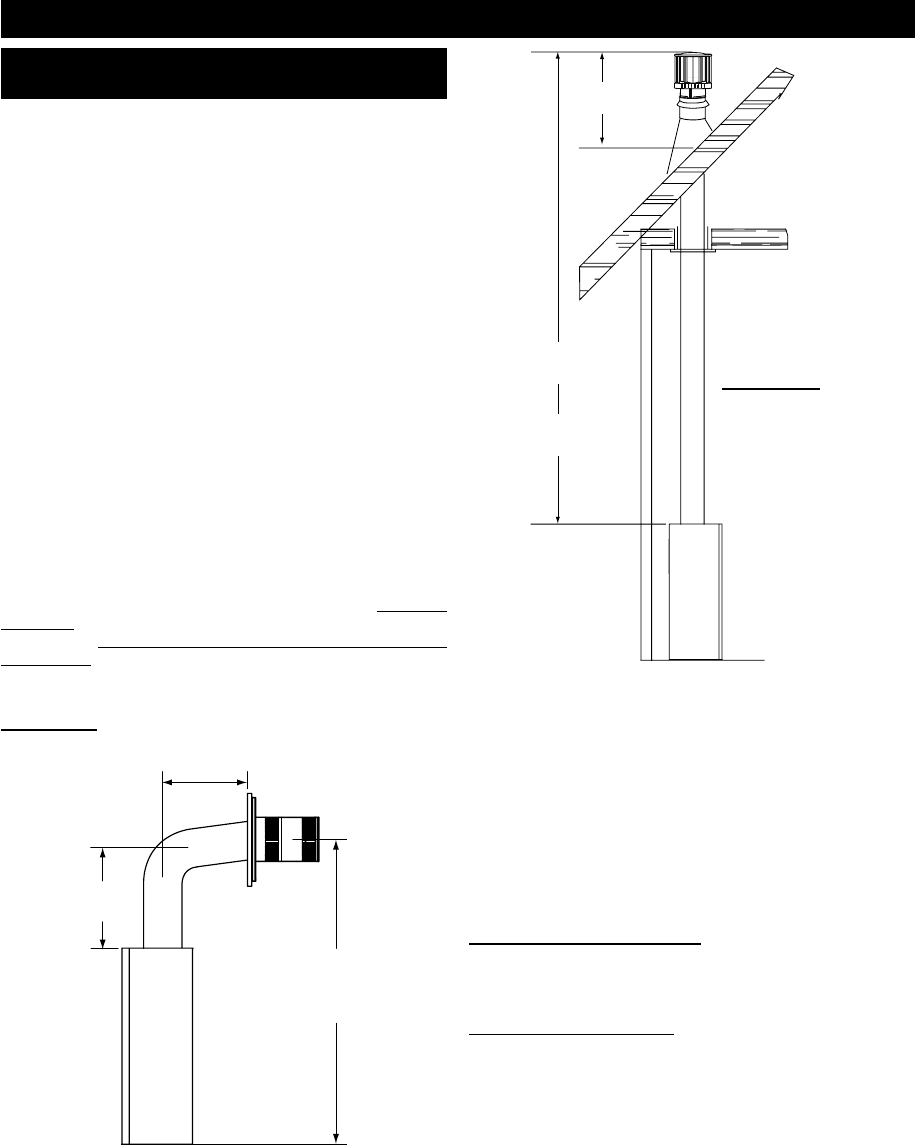

16”

MINIMUM

40 FEET

MAXIMUM

3 FEET

MINIMUM

FIGURE 3b

When using Wolf Steel Ltd.venting components, use only approved

Wolf Steel Ltd. fl exible vent components with the following termina-

tion kits: WALL TERMINAL KIT GD622, or 1/12 TO 7/12 PITCH

ROOF TERMINAL KIT GD610, 8/12 TO 12/12 ROOF TERMINAL KIT

GD611, FLAT ROOF TERMINAL KIT GD612. With fl exible venting, in

conjunction with the various terminations, use either the 5 foot vent

kit GD620 or the 10 foot vent kit GD630. These vent kits allow for

either horizontal or vertical venting of the fi replace.

The maximum allowable vertical vent length is 40 feet. The

maximum number of allowable 8” vent connections is three hori-

zontally or vertically (excluding the fi replace and the air terminal

connections).

For optimum fl ame appearance and fi replace performance, keep the

vent length and number of elbows to a minimum. The air terminal must

remain unobstructed at all times. Examine the air terminal at least

once a year to verify that it is unobstructed and undamaged.

When venting, the horizontal run must be kept to a maximum

of 20 feet. If a 20 foot horizontal run is required, the fireplace

must have a minimum vertical rise immediately off the fire-

place of 57“. When terminating vertically, the vertical rise is

a minimum 3 feet and a maximum 40 feet above the fireplace.

FIGURES 3a-b.

VENTING

VENTING LENGTHS AND AIR TERMINAL

LOCATIONS

* For optimum performance, it is recommended that all hori-

zontal runs have a minimum ¼“ rise per foot.

Provide a means for visually checking the vent connection to

the fireplace after the fireplace is installed.

Do not allow the inside liner to bunch up on horizontal or vertical

runs and elbows. Keep it pulled tight. A 3/4” air gap between the

inner and outer liner all around is required for safe operation.

Use a firestop when penetrating interior walls, floor or ceil-

ing.

For safe and proper operation of the fireplace follow the venting

instruction exactly.

If vertical rises greater than 57“ are necessary, the increased

rise must be deducted from the horizontal run.

HORIZONTAL VENT SECTIONS: A minimum clearance of 2” all

around the vent pipe on all horizontal runs to combustibles is required

except for clearances in fi replace enclosures**. Use fi restop spacer

assembly W010-1797 (supplied).

VERTICAL VENT SECTIONS: A minimum of 1” all around the vent

pipe on all vertical runs to combustibles is required except for clear-

ances in fi replace enclosures**. Use fi restop spacer W615-0075

(not supplied).

** Horizontal and vertical sections require 5” and 9” clearance from

combustibles, respectively. See minimum enclosure clearances

section.

For safe and proper operation of the fi replace follow the venting

instructions exactly.

Deviation from the minimum vertical vent length can create diffi culty

in burner start-up and/or carboning.

Provide a means for visually checking the vent connection to the

fi replace after the fi replace is installed.

Vent lengths that pass through unheated spaces (attics, garages,

crawl spaces) should be insulated with the insulation wrapped in a

protective sleeve to minimize condensation.

71

3

/4”

MINIMUM

PLUS RISE*

24” MAXIMUM

13

1

/2”

MINIMUM

FIGURE 3a