JIMMY SERIES HYDRAULIC REBAR BENDERS — OPERATION AND PARTS MANUAL — REV. #9 (01/04/08) — PAGE 20

PREVENTIVE MAINTENANCE

Preventive maintenance should be performed on a daily or

weekly basis depending on the amount and working use. A

higher than normal operating pressure could indicate a need

for immediate maintenance.

A clean well lubricated rebar bender will operate faster and

smoother and will allow for more accurate readings from

pump pressure gauges.

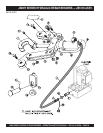

PUMP MAINTENANCE (Cleaning and Lubrication)

1. Remove the side plates on the rebar bender to expose

moving parts. Clean all moving parts with a clean rag

and solvent.

2. Check the cylinder on all models for leaks.

3. Lubricate all moving parts with

high pressure grease

.

4. For rebar bender models with cables (Models JB11090

and JB9180), lubricate the five grease fittings daily or

after approximately 50 rebar bend operations. Check

hydraulic cables daily for fraying.

4. For rebar models JB135 and JB7135, visually check for

dents or cracks in the side plates. Replace plates

immediately if damaged. Clean and lubricate both rollers

to insure smooth rotation.

5. Check hydraulic oil every 40 hours of operation. Add

hydraulic oil if necessary. Oil can be added by removing

the vent cap. Use a funnel.

ADDING HYDRAULIC OIL

1. Make sure electric motor is OFF.

2. Depressurize system by placing pump control lever in

the

neutral

position. Disconnect hydraulic hose from

port A of system.

3. Remove

vent cap

on top plate of reservoir. Visually

inspect to see if oil level is low. Oil level should be about

2 inches (50 mm) from top of reservoir plate.

4. Using a funnel, add oil to about 2 inches (50 mm) from

top of reservoir plate.

JIMMY SERIES HYDRAULIC REBAR BENDERS — MAINTENANCE

STORAGE

When the rebar bender and electric hydraulic pump are not

used, please store in a clean dry location out of the reach of

children and away from unauthorized personnel.

Be sure that all dust caps are attached to their respective

hoses and the hand-held remote control cable and pump

power cord are neatly wrapped.

CHANGING HYDRAULIC OIL

1. Change hydraulic oil

once a year

.

2. Remove drain plug, tilt the pump, then pour used fluid

into a sealable container.

3. Dispose the hydraulic fluid in accordance with local

regulations.

4. Install drain cap.

5. Remove vent cap and fill with recommended type

hydraulic oil.

NOTE

Completely change hydraulic oil

every

300 hours

of operation.

Change the oil more frequently when

pump is used in an extremely dusty

environment or when the oil has

been overheated.

NOTE

Use only good quality hydraulic oil.

Multiquip recommends Mobil DTE

15M or equivalent. NEVER use

brake fluid, transmission fluid,

turbine oil, motor oil alcohol glycerin

etc. Use of other than the

recommended hydraulic oil will void warranty and damage the

pump and hydraulic hose used in the rebar bending application.